Metal Fabrication of Custom Steel Parts

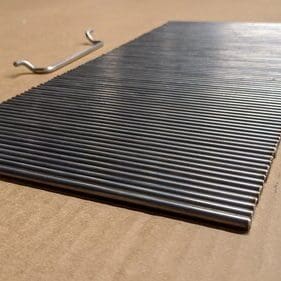

Approved Sheet Metal (ASM) is the fastest source of custom-formed steel sheet metal parts. Parts typically formed with this material are from the Galvenneal and Galvanized grades of steel, we also work in many other different grades as well. Steel is a great option for appearance as well as structural parts. We manufacture a variety of custom sheet metal parts, such as covers, shields, plates, fixtures, brackets, consoles, chassis, and more, in 2-10 days, in both prototype (1) to low volume production (up to 5,000) quantities. Steel is a very popular choice for sheet metal fabrication, we have what it takes to get your parts on your dock on time and right the first time!

Steel parts are used in a variety of industries including electrical, medical, robotics, instrumentation, aerospace, and many more. Fabricating customer steel parts to order is a well-established process in the metal industry. In most cases, steel metal parts are produced by cutting, bending, and then welding them together. The cutting process can be done using a variety of methods, including laser cutting, waterjet cutting, and plasma cutting. Once the steel sheet metal parts have been cut to size, they are then bent into shape using a press brake. Finally, the parts are welded together using either TIG or MIG welding. This entire process can be completed in-house at a metal fabrication like Approved Sheet Metal.

Whether you need one part or one hundred, we can help you obtain the perfect steel part for your project. Contact us today to learn more about our steel fabrication services or request a quote.