The most common sheet metal fabrication materials used in forming custom sheet metal parts

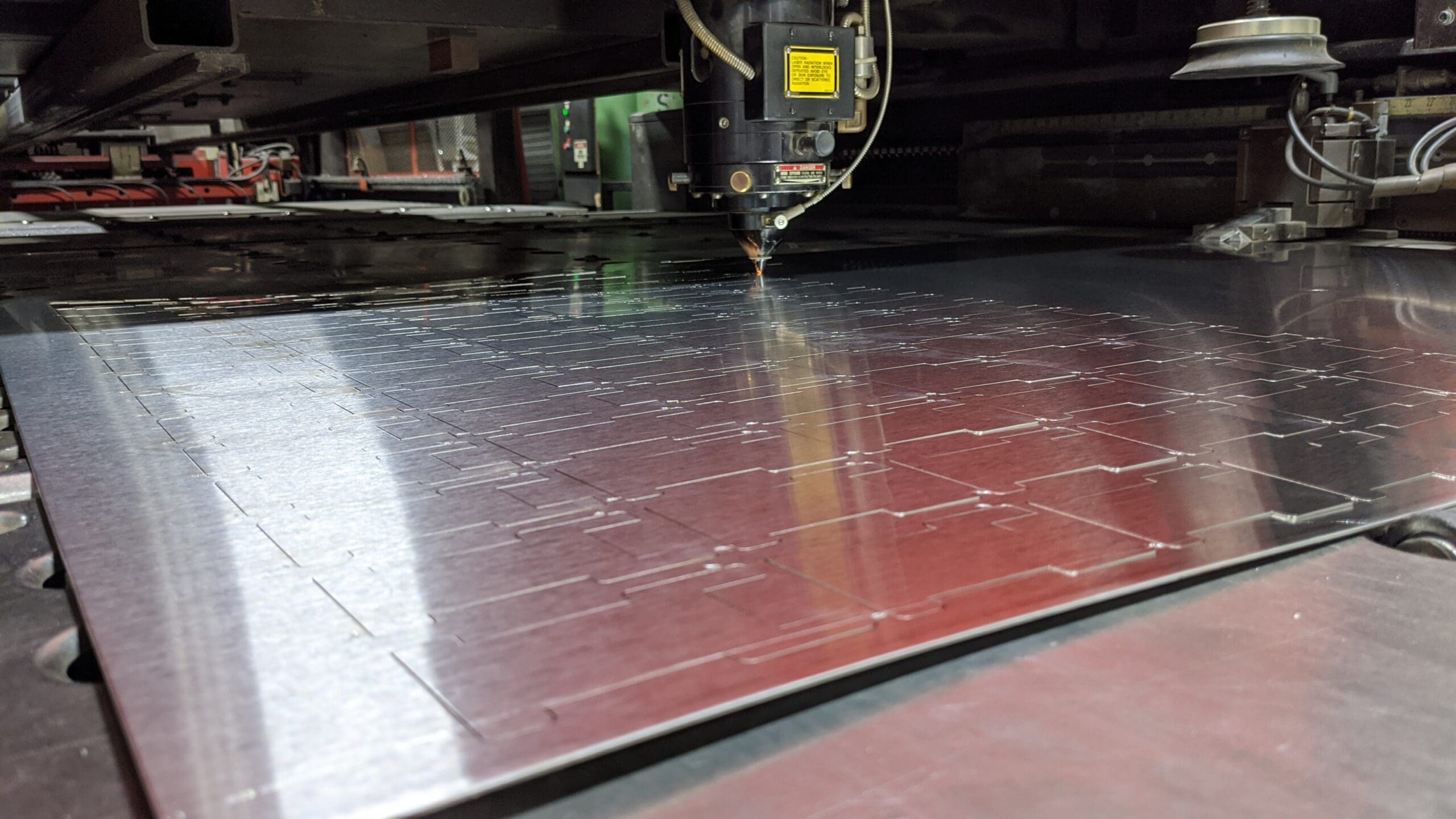

At our state-of-the-art facility, we are able to fabricate precision sheet metal parts out of a variety of materials, including aluminum, cold-rolled steel, stainless steel, and copper.

Our highly skilled team has the experience and expertise to work with even the most challenging specifications. In addition, we utilize the latest computer-aided design and manufacturing technology to ensure that every part meets the highest standards of quality. Whether you need a single prototype or a large production run, we are confident that we can exceed your expectations.

Aluminum

Parts typically formed with this material are from the 5052-H32 grade of aluminum, we also work in many other different grades as well. Stock thicknesses for our Aluminum 5051-H32 range from 0.020” to 0.125”

Stainless Steel

Parts typically formed with this material are from the 304/304L & 316L grades of stainless steel, we also work in many other different grades as well. Stainless steel is a great option for appearance parts.

Cold Rolled Steel

Parts typically formed with this material are of the 1008 alloy. Cold rolled steels come in a variety of thicknesses and provide excellent flatness tolerance, surface finish, and press brake formability.

Copper

ASM has over three decades of sheet metal fabrication experience, copper is a popular choice for the fabrication of custom bus bars and custom-formed electrical contacts, we have what it takes to get your parts on your dock on time and right the first time!

Steel

Approved Sheet Metal (ASM) is the fastest source of custom-formed steel sheet metal parts. Parts typically formed with this material are Galvenneal and Galvanized grades of steel, we also work in many other different grades as well. Give us a shot on your next project!