How Approved Sheet Metal supported an information technology and services company during product development and fabricated quick-turn prototypes to meet all critical requirements.

The Company

Gradient Technologies’s mission is to secure the connected world, deploying to anything that runs code.. Gradient has developed a solution called Security Mesh to continually protect IT, OT, and IoT critical infrastructure assets of enterprises against ransomware and malware.

Industry: Information Technology and Services

Location: Boston, Massachusetts

The Project

The Challenge:

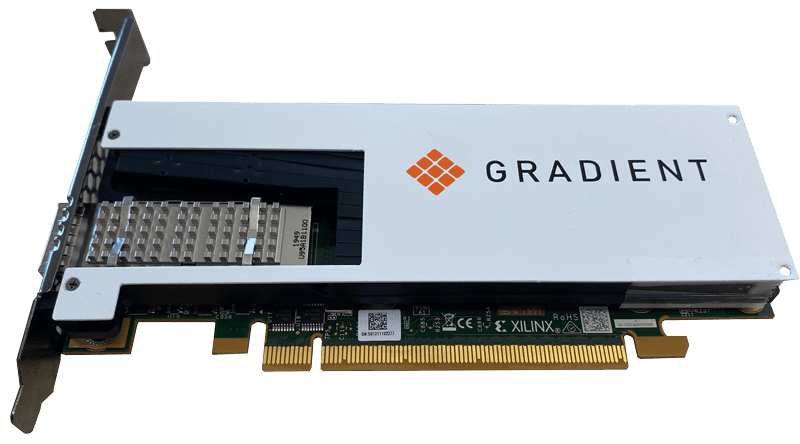

Gradient Technologies needed to brand both a PCI card and a server-based appliance. As a startup, their existing team had minimal experience designing and purchasing sheet metal components.

The Solution:

Approved Sheet Metal worked closely with Gradient during the product development phase of their process to help propose, develop, and finalize designs before fabricating physical prototypes.

The Outcome:

Known for providing quick-turn sheet metal fabrication services, Approved Sheet Metal delivered prototypes that met all specifications and then made a small production run. The prototypes exceeded Gradient’s expectations as Approved Sheet Metal, not only incorporated colors and logo but also elements of Gradient’s branding into the sheet metal design while still meeting mechanical requirements (such as air flow).

From Cybersecurity to Sheet Metal

Cybersecurity breaches pose a growing risk to organizations all over the world, with global

spending on cybersecurity products and services projected to exceed $300 billion in2024.exceed $300 billion in 2024.

Despite these investments, the pace, sophistication, and impact of ransomware and malware attacks have increased. Recent high-profile breaches like the SolarWinds and Colonial Pipeline cyber attacks, with the latter forcing a six-day pipeline shut down that affected gas availability in 17 states and disrupted airlines, have been impossible to ignore, demonstrating just how vulnerable government and private industries are in the face of these risks.

Gradient is responding to the growing demand for better cybersecurity. They build innovative software solutions incorporating Zero Trust Architecture and new technologies that mitigate the credential compromises and malware driving today’s sophisticated ransomware. Together these capabilities not only detect and monitor cybersecurity threats, but they also prevent these incidents from occurring in the first place.

Part of this ambitious approach involves building appliances that enable customers to operate this software in specialized on-premise environments where they may not have easy access to publicly available servers.

Partnering with Approved Sheet Metal

When Gradient was ready to brand an appliance and a PCI card to market to their customers requiring an on-premises solution, they knew they needed to find the right sheet metal fabrication shop for the job.

“We were looking for a real partner to work with us. We needed more than just a shop that could manufacture these components. We needed a shop that could step up and support us during product development,” said George Harper, VP Product & Partnerships at Gradient.

Gradient learned about Approved Sheet Metal through a colleague that had worked with the shop before. He reached out to the shop’s Company Leader Steve Lynch to schedule a meeting.

Key Differentiators

Formed in 2020, Approved Sheet Metal was built by leaders in the sheet metal fabrication industry. They leverage technology to get parts quoted, fabricated, and delivered faster than anyone. They are dedicated to their craft and proud to be making parts in America.

Precision Prototype Sheet Metal from Conception to Completion

Approved Sheet Metal takes hand sketches, detailed prints, and CAD models requiring first article inspection to turn ideas into physical sheet metal parts. They understand how important it is to hit deadlines and are committed to supporting customers’ journeys from conception to completion.

Wide Range of Capabilities

Approved Sheet Metal has 30+ years of experience, 20,000+ sq. feet of manufacturing space, and state-of-the-art processes and equipment from quoting and programming to punching, forming, hardware insertion, welding, finishing, and inspection.

Quick Turnaround Time

Approved Sheet Metal responds to all quotes within 4 hours and turns around rapid prototypes in record time. They also have a same-day rush service for flat sheet metal parts.

An Efficient, Collaborative, Creative Partnership

Since Gradient didn’t have onsite expertise designing 3D CAD models, they knew they needed Approved Sheet Metal’s help during the design phase. They sent their ideas over in a PowerPoint presentation, providing sample measurements of their existing PCI cards and appliances. The two teams collaborated efficiently to further develop the concept and determine ideal materials and finishing.

“Steve quickly grasped what we were trying to achieve. He really stepped up to support us in areas that most vendors would have pushed back on,” said George.

Approved Sheet Metal prepared the 3D CAD model and submitted it to Gradient for final approval. Once it was approved, the shop turned around unfinished prototypes in 7 days so Gradient could test-fit the pieces.

Testing revealed that some of the measurements were off, so Approved Sheet Metal quickly made the required changes and fabricated the final products. This process involved some light assembly work (e.g. attaching screws and mounting plates), which Approved Sheet Metal completed in-house.

Approved Sheet Metal delivered the initial prototypes for the products, then made a small production run.

“It was a pleasure working with Approved Sheet Metal. They were responsive and fast. Most importantly, the results exceeded our expectations as they cleverly incorporated elements of the brand, beyond just colors and logo, into the sheet metal design itself without impacting key mechanical requirements, such as air flow,” said George.

“Rapid sheet metal prototypes and low-volume production sheet metal fabrications are our sweet spot here at Approved Sheet Metal. We were happy to put our expertise to work for Gradient,” said Steve.