How Approved Sheet Metal collaborated with a renewables & environment customer to save them time and money on high-quality parts.

The Company

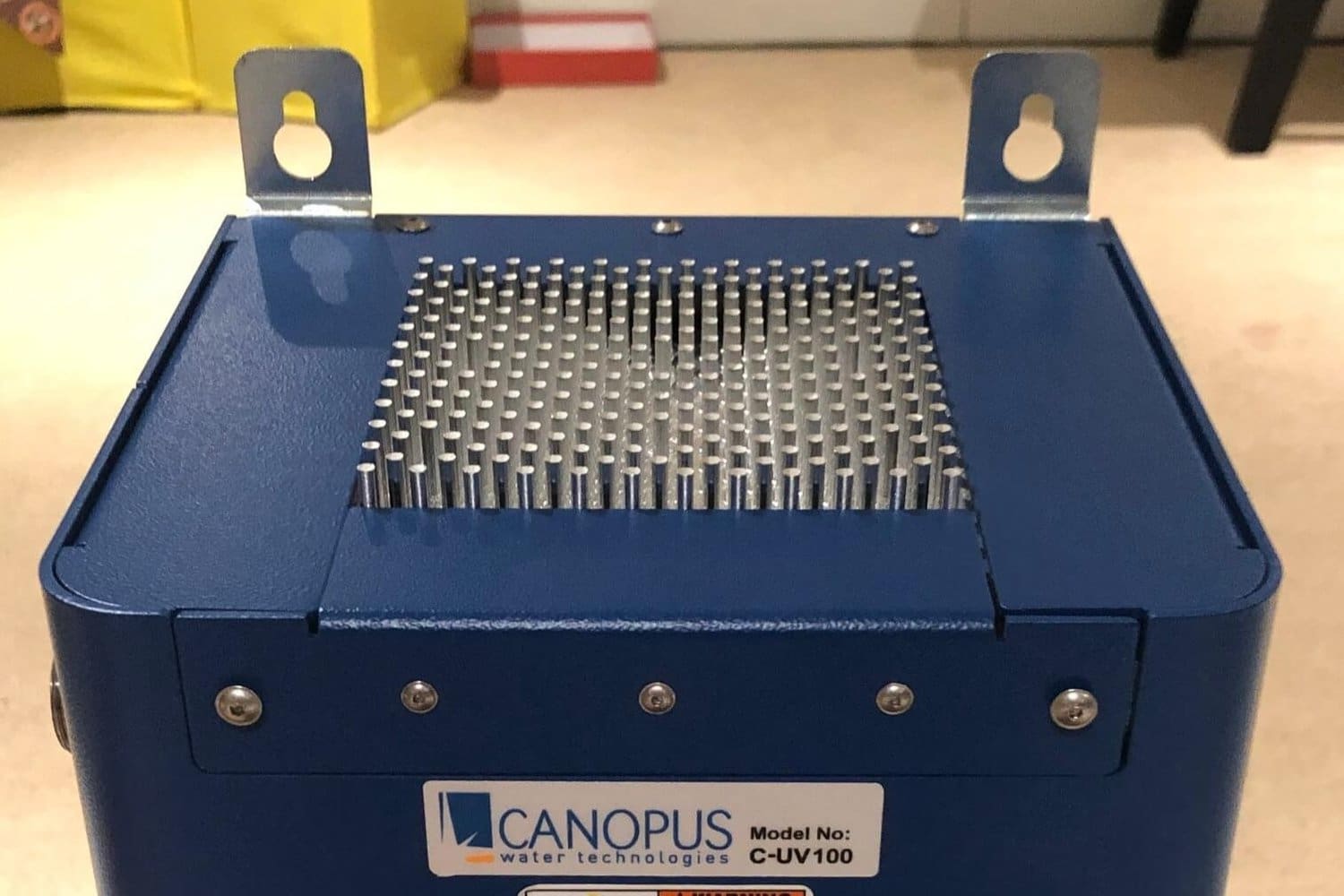

Canopus Water Technologies Inc. is a developer and manufacturer of non-chemical water disinfection products for residential, industrial, and commercial applications. The Canopus technology development team brings a unique systems approach to a market in dire need of innovation.

Industry: Renewables & Environment

Location: Windham, New Hampshire

The Project

The Challenge:

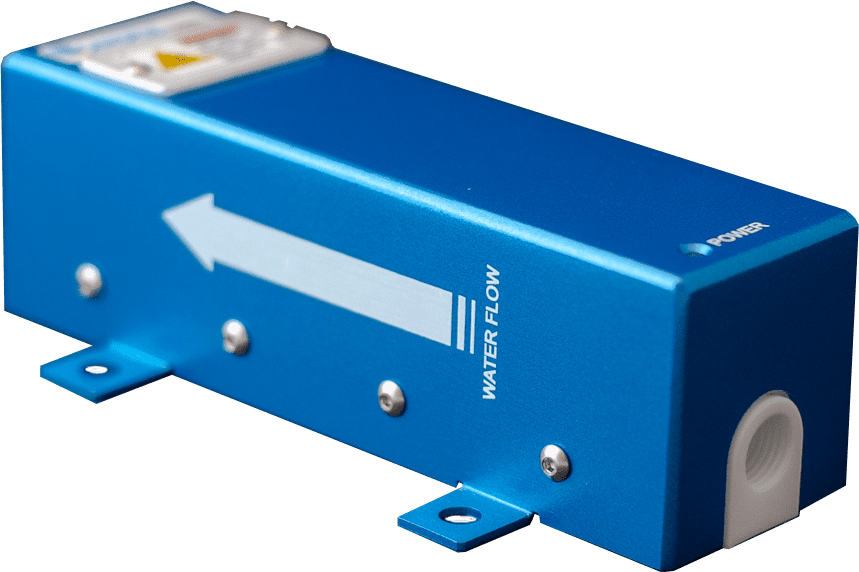

Canopus needed 12 unique parts for their C-UV100 chemical-free water purification device turned around as quickly as possible.

The Solution:

Approved Sheet Metal collaborated with Canopus to design and fabricate the parts they needed quickly and cost-effectively.

The Outcome:

Approved Sheet Metal delivered 12 unique parts to Canopus within 7 days.

Quick Response and Good Communication

Canopus was looking for a sheet metal fabrication company to make an assembly of parts for their chemical-free water purification device. They came across Approved Sheet Metal in an online search, reached out for a quote, and were surprised to receive such a fast response.

“The fast response was key for us. We’re a startup company, so our lives are counted by minutes, not by weeks and months,” said Souheil Benzerrouk, President & CEO of Canopus. “It’s the nature of our business to have to turn parts around quickly, whether a customer needs a specific part or we’re trying to secure limited space in a lab for testing and evaluations.”

Souheil was immediately impressed during his initial conversation with Steve Lynch, Company Leader at Approved Sheet Metal.

“Knowing what to expect from a vendor is huge. We can’t let our customers down, which means we expect our partners not to let us down,“ said Souheil. “Steve was very personable. He communicated clearly and effectively to let us know exactly what he could do for us and what timeframe we were looking at.”

Effective Collaboration and Expert Recommendations

Canopus decided to partner with Approved Sheet Metal, and the two teams collaborated during the design phase. They had to consider factors like cost and the volume of parts that needed fabrication. Souheil drove the assembly of parts over to Approved Sheet Metal’s facility in Hudson, NH, so the two companies could determine how to make it better and more cost-effective.

“That support was significant for us,” said Souheil. “My team has mechanical engineering expertise, but we don’t have sheet metal expertise. Approved Sheet Metal provided the sheet metal expertise we needed.”

Knowing that cost and speed were major concerns for Souheil, Steve recommended powder coating the parts instead of using wet paint.

“I knew that switching from wet paint to powder coating would guarantee high-quality, durable parts, while also saving Canopus time and money,” said Steve.

Canopus had such a great experience during this project that they have made Approved Sheet Metal a preferred vendor for sheet metal fabricated parts.

“We enjoyed working with Canopus on this fun project and aligning ourselves with their mission to promote water safety without the use of chemicals,” said Steve.

Key Differentiators

Formed in 2020, Approved Sheet Metal was built by leaders in the sheet metal fabrication industry. They leverage technology to get parts quoted, fabricated, and delivered faster than anyone. They are dedicated to their craft and proud to be making parts in America.

Precision Prototype Sheet Metal from Conception to Completion

Approved Sheet Metal takes hand sketches, detailed prints, and CAD models requiring first article inspection to turn ideas into physical sheet metal parts. They understand how important it is to hit deadlines and are committed to supporting customers’ journeys from conception to completion.

Wide Range of Capabilities

Approved Sheet Metal has 30+ years of experience, 20,000+ sq. feet of manufacturing space, and state-of-the-art processes and equipment from quoting and programming to punching, forming, hardware insertion, welding, finishing, and inspection.

Quick Turnaround Time

Approved Sheet Metal responds to all quotes within 4 hours and turns around rapid prototypes in record time. They also have a same-day rush service for flat sheet metal parts.