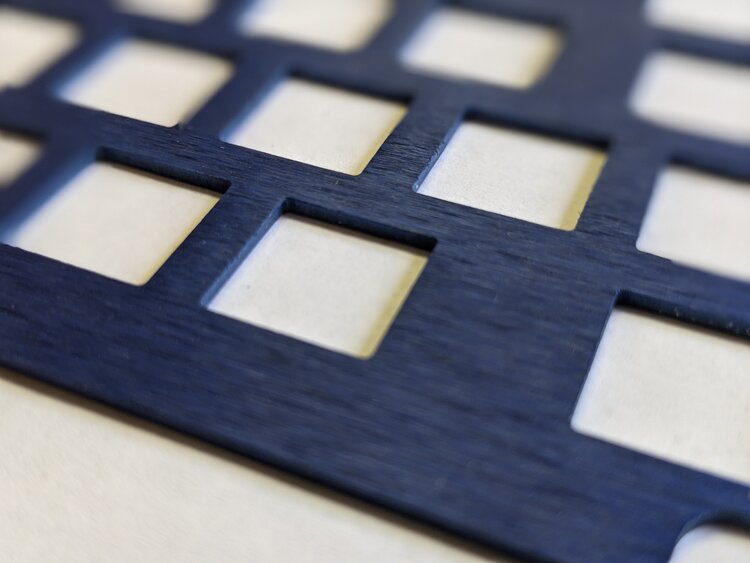

Color Anodize Sheet Metal for Beautiful Parts

When you color anodize sheet metal it adds a thicker, oxide layer over the aluminum to protect it from rust and wear. Anodizing not only protects aluminum alloys from weather and the elements, it can also provide electrical insulation. It’s especially important for parts that are routinely or constantly submerged in water.

When you anodize, you also get a better-looking product: it gives aluminum a smoother, scratch-free surface with no nicks or bumps.

At Approved Sheet Metal, we make great parts, but we like to have a little fun, too. And what better way to dress up your next project than with color-anodizing? The oxide layer created during anodization is porous, which allows for the introduction of color. For you creative types out there, that means aluminum parts can be more exciting than your standard metal, black, or clear finishes.

Images Courtesy of US Specialty Color Corporation

Black BK Excel

Blue 4A

Blue A

Bordeaux R

Bronze 2LN

Brown BL

Brown CAMO

Brown GL

Copper BF

Deep Red L

Fast Blue 2LWN

Fast Blue GN

Fast Gold LN

Gold EAN

Golden Orange RLW

Gold N (F.A.O.)

Gold S

Green AEN

Green B Conc

Green SG-S

Grey BL

Grey NLN

Neon Pink

Olive Drab

Olive EG

Orange 2B

Orange 3A

Teal

Turquoise PLWN

Violet 3D

Violet DS

Violet MRB

Yellow 3GL

Yellow 4A

Yellow D

Why Color-Anodize?

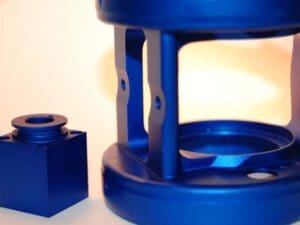

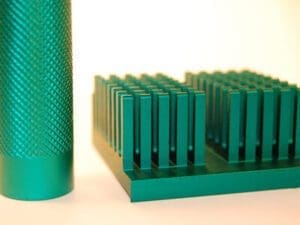

There’s a huge range of colors available for color anodizing. Make your next part stand out with one of these hues:

- Blue

- Green

- Red

- Orange

- Purple

- Teal

- Brown

- Gold

- Grey

- Pink

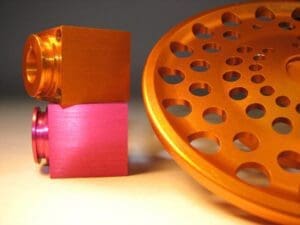

When to Color-Anodize

Color anodize if you want your part to grab attention (if it’s part of an emergency feature, for example), coordinate different pieces for ease of assembly, or simply stand out.

Perfect for products like:

Aluminum Artwork | Aluminum Signages | Communication Tools

Automotive Parts | Medical Devices | Educational Instruments

Dock Components