Laser Cutting Sheet Metal Parts

At Approved Sheet Metal, we offer laser cutting services to provide custom parts for a variety of industries. Our laser cutting technology allows for precise cuts with minimal material waste, saving our clients time and money in the production process. In addition, laser cutting offers flexibility in design and the ability to handle a range of material types and thicknesses. Whether it is small precision parts or larger components, our laser cutting services can meet our clients' needs. With fast turnaround times and exceptional attention to detail, laser cutting provides an efficient and cost-effective solution for custom parts. Contact us today to learn more about the value of laser cut parts from Approved Sheet Metal.

Our laser operators have 15+ years of experience in laser cutting prototype to low volume production quantities. In addition to laser cutting, other sheet metal fabrication capabilities that Approved Sheet Metal has extensive experience in include:

- Punch Forming

- Forming

- Welding

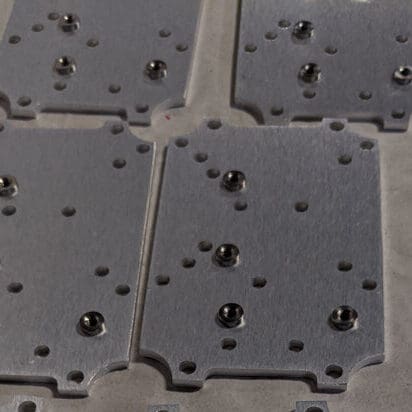

- Hardware Insertion

- Assembly

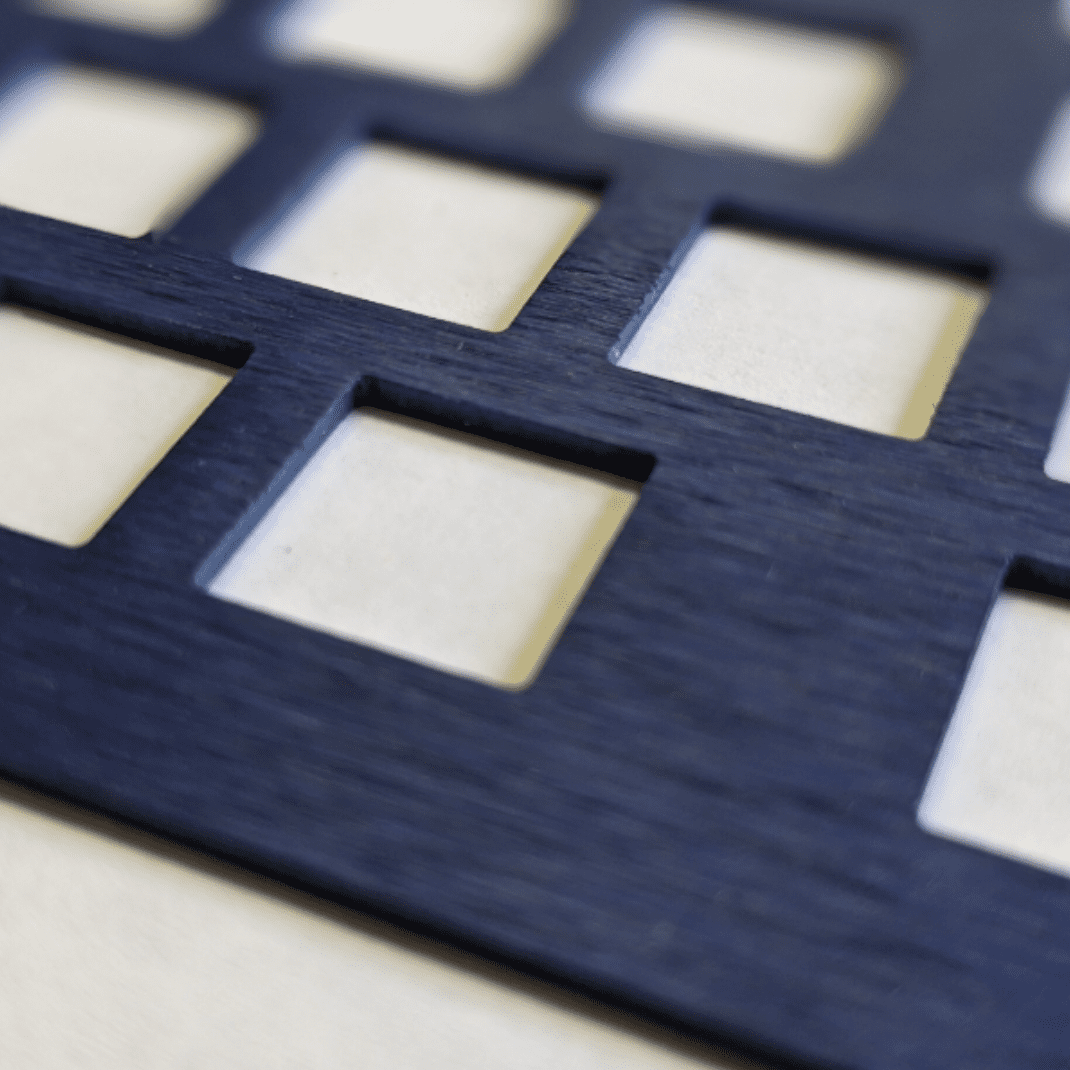

- Powder Coating, Silk Screening, Plating and more.

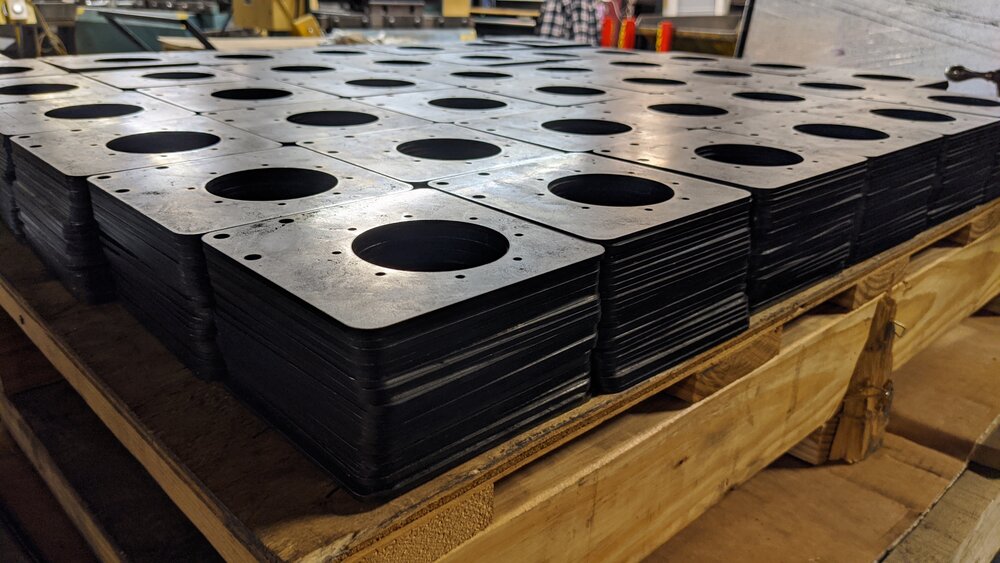

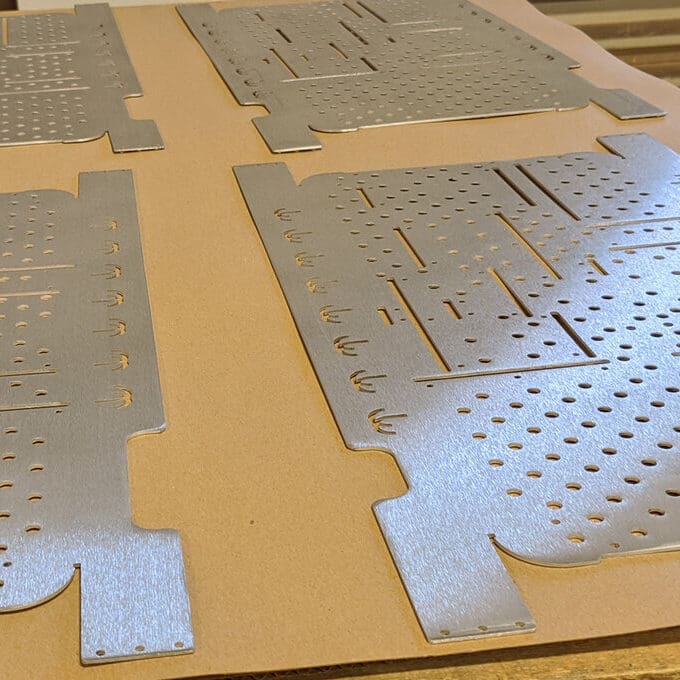

Check out the gallery below to see what we can do for you!

Laser Cutting Design Guidelines

| Maximum Size |

|

| Minimum Part Size | 0.25 in. x 0.25 in. |

| Material Thicknesses | 0.024 in. - 0.250 in. |

| Tolerances |

|

| Material | Grade | Thicknesses Available |

| Aluminum |

| 0.025 in. - 0.250 in. (0.635mm - 6.35mm) |

| Steel |

| 0.025 in. - 0.250 in. (0.635mm - 6.35mm) |

| Stainless Steel |

| 0.025 in. - 0.250 in. (0.635mm - 6.35mm) |

| Copper |

| 0.025 in - 0.125 in. (0.635mm - 3.175) |

| Brass |

| 0.025 in. - 0.125 in. (0.635mm - 3.175) |

Frequently Asked Questions (FAQS)

What is your lead time for flat parts?

We can ship parts as fast as same day! For more details check out our Same Day Rush page.

What tolerances can you achieve for laser cut parts?

We can achieve tolerances of +/- 0.003”

What considerations should I think about when designing parts?

There are ways to design parts, and specific features, that will help reduce back-and-forth and ensure that you get what you need out of your part. Take a look at our Sheet Metal Design for Manufacturing eBook to see best practices - See the eBook