Last updated on January 2nd, 2025 at 11:04 am

Do you know what type of finish your custom sheet metal part needs?

If you’re like many customers, you might not even know what your options are!

As leaders in metal fabrication, we’re well-versed in the different classes of finishing options and can provide you with the information you need to make an informed decision.

Table of Contents

- 1 The 3 Classes of Sheet Metal Finish

- 2 Recommended Default Sheet Metal Tolerances

- 3 Sheet Metal Finishes FAQ

- 3.0.1 What are the different classes of sheet metal finish?

- 3.0.2 What is a Class A sheet metal finish and when is it used?

- 3.0.3 What is a Class B sheet metal finish and what are its variations?

- 3.0.4 What is a Class C sheet metal finish and when is it used?

- 3.0.5 How can Approved Sheet Metal help determine the right finish for my part?

The 3 Classes of Sheet Metal Finish

There are many different ways to classify finishes for custom sheet metal parts. At Approved Sheet Metal, we’ve streamlined the options and made an easy-to-follow framework. Request your sheet metal finished as either A, B, or C—the grades correspond to "best, better, and good" in terms of quality:

- Class A has the best, finest finish and is always the most expensive option

- Class B yields a slightly less fine finish and is a more economical option

- Class C is the most basic finish and is the least expensive option

While some finishes can impact lead times slightly, cost and quality are the major differentiators to consider. Customers should expect a ± 8% price difference between each of the finish classes.

Wondering which class of finish suits your project's requirements? Let's take a closer look at all of them.

Class A

Described as a "cosmetic finish," a class A finish is free of any surface imperfections or press brake marks.

Class A finishes are typically reserved for external facing parts, such as medical devices and food-grade products. Parts that will be anodized also require a Class A finish.

To achieve such a light grain finish, we use a Timesavers or a stroke sander to remove all surface imperfections. When packaging parts for shipment, we layer each one in paper to protect the surface.

Class B

Class B is often referred to as the "standard" finish class. These finishes are not considered cosmetic, so you can expect some surface imperfections, including press brake marks. Typically, parts that are plated fall into this class.

Class B finishes are further narrowed down into three categories, defined by their processes:

- B-1 indicates a standard finish achieved with a Timesavers. All sharp edges are removed, and the parts have a light grain linear finish.

- B-2 indicates a manual dual action (DA) or orbital sand finish. All sharp edges are removed, and parts have an orbital or nonlinear finish.

- B-3 is also known as a "tumble finish." Parts are put into a vibratory tumbler machine to achieve a uniform, smooth, nonlinear finish. At our metal fabrication shop, we reserve this type of finish for small parts due to the size limitations of our Timesavers.

Class C

Also known as a "mill finish," Class C is the default finish at most sheet metal fabrication shops, including Approved Sheet Metal.

Parts with a Class C finish are smooth enough that they won’t cut anyone, and there won't be a heavy burr, but there will be some surface imperfections, such as press brake marks. We don't employ our Timesavers machines or conduct any DA sanding.

Class C is our shop standard for parts that will be painted or powder coated, as both treatments are thick enough to cover Class C surface imperfections.

Industry Standards and Specifications

Understanding and adhering to industry standards is crucial in sheet metal fabrication to ensure quality, safety, and compatibility. Key standards include:

- ASTM International Standards: ASTM provides widely recognized standards for materials and processes in sheet metal fabrication. For instance, ASTM A480 outlines the general requirements for flat-rolled stainless and heat-resisting steel plate, sheet, and strip, including finish designations.

- ISO Standards: The International Organization for Standardization (ISO) offers standards like ISO 9001 for quality management systems, ensuring that fabricated parts meet customer and regulatory requirements.

- ANSI Standards: The American National Standards Institute (ANSI) oversees standards for products, services, and systems in the U.S., ensuring consistency and safety in sheet metal fabrication.

Adhering to these standards ensures that fabricated parts meet industry benchmarks for quality and performance.

Design Considerations and Limitations

When designing sheet metal parts, several factors influence manufacturability and functionality:

- Material Selection: Choosing the appropriate material affects the part's strength, weight, and corrosion resistance. Common materials include aluminum, stainless steel, and mild steel, each with distinct properties.

- Thickness Constraints: Material thickness impacts the bending process and the achievable bend radius. For example, in certain finishing processes like tumbling, stainless steel parts must be at least 0.030" thick to withstand the process without deformation.

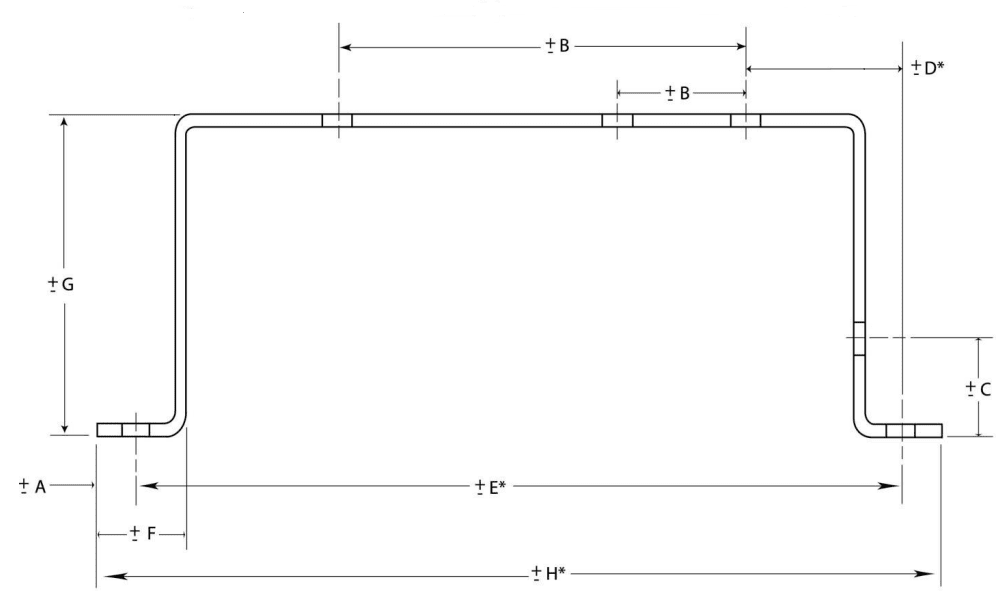

- Bend Radii: Maintaining appropriate bend radii prevents material cracking and ensures structural integrity. It's essential to follow guidelines specific to the chosen material and thickness.

- Tolerance Specifications: Defining acceptable tolerances is vital for parts that require precise fits, especially in assemblies where multiple components interact.

- Finishing Processes: The chosen finish can affect both aesthetics and functionality. Options include powder coating, anodizing, and plating, each offering different levels of protection and appearance.

Considering these factors during the design phase can lead to more efficient manufacturing processes and higher-quality end products.

Approved Sheet Metal Can Help Determine the Right Finish for Your Part

Still not sure which finish is suitable for your part? Don't worry—we can help! We just need some basic information about the end use application.

Is it an internal part that will never be seen or touched? Will it be painted or powder coated? In either of these cases, we’ll recommend a class C finish to save you money.

Are you taking a part on the road to a trade show or conducting a demonstration in a conference room? A class-A finish will give your part a polished look and help you wow prospective customers.

If these details aren’t on your print, share them with us when you request a quote. If you don't specify a finish, we'll leverage our understanding of your project and our years of experience to make the best determination and contact you with any questions.

Our goal is to deliver superior sheet metal parts to your desk quickly and make the entire process easy for you. Ready to tackle your next metal fabrication project? Get started today by requesting a quote.

Sheet Metal Finishes FAQ

The different classes of sheet metal finish are A, B, and C. These grades correspond to "best, better, and good" in terms of quality.

A Class A finish is a "cosmetic finish" that is free of surface imperfections or press brake marks. It is typically used for external-facing parts, such as medical devices and food-grade products, as well as parts that will be anodized.

Class B is the "standard" finish class and may have some surface imperfections, including press brake marks. It is often used for plated parts. Class B finishes are further categorized as B-1, B-2, and B-3:

- B-1: Achieved with a Timesavers, it has a light grain linear finish.

- B-2: Achieved with manual dual action (DA) or orbital sanding, it has an orbital or nonlinear finish.

- B-3: Known as a "tumble finish," it is achieved using a vibratory tumbler machine, resulting in a uniform, smooth, nonlinear finish.

Class C, also known as a "mill finish," is the default finish at most sheet metal fabrication shops. It has some surface imperfections, such as press brake marks, but is smooth enough to prevent cutting. Class C is commonly used for parts that will be painted or powder coated, as these treatments can cover the surface imperfections.

Approved Sheet Metal can assist in determining the right finish based on the end use application of the part. By understanding whether the part will be seen or touched, if it will be painted or powder coated, or if it will be used for showcasing purposes, they can recommend the appropriate finish. If these details are not specified, their experience and understanding of the project will be used to make the best determination, and they will reach out with any questions.