Last updated on June 25th, 2024 at 09:58 am

At Approved Sheet Metal, we aim for total transparency when providing a lead time with your quote, even if the news isn’t ideal.

When we received a recent quote request for parts requiring custom machining, we had to tell the customer that their request would involve external vendors and that their lead time would be five weeks—significantly longer than our average turnaround time.

But it didn’t have to be that way. In this particular case, avoiding custom machining would have brought the customer’s lead time into the 2-3 week range that they desired. In many cases, our custom fabrication shop can expedite quick-turn flat parts in as little as one day!

Table of Contents

How to Get Custom Sheet Metal Parts Rapidly

By paying close attention to four key factors, you can reduce or eliminate the need for outside services, ensure your parts are easy to make, and enjoy the fastest possible delivery timeline. Here’s a closer look at what to do.

Hack #1: Specialized machining processes

Like most sheet metal fabrication companies, our shop doesn’t offer custom machining in-house. Our focus is on precision sheet metal fabrication services for production volumes of up to 5,000 parts, and our fastest turnarounds are for parts that remain within that scope.

*****UPDATE DECEMBER 2023*****

Approved Sheet Metal has acquired a CNC Machine Shop to provide complementary machining services for sheet metal fabrication projects, learn more here.

Hack #2: Complicated finishing requirements

Our custom fabrication shop offers powder coating services through an in-house partner vendor located in our building. And our plating partners typically have lead times of only a few days. But other finishing services that come from outside the ASM family can take notably longer. We recommend avoiding finishing services requiring significant coordination with outside vendors when possible.

If you need finishing services like powder coating or wet paint, keep in mind that requesting custom colors can make an otherwise simple request much more complicated. Custom colors can be difficult to source in a timely manner and may have a minimum purchase price. You can reduce your lead time by selecting a stock color and texture.

Hack #3: Custom hardware

Approved Sheet Metal offers hardware insertion for your sheet metal parts—a relatively quick process for metal fabrication companies as long as the hardware is readily available!

When designing your part, do your research to ensure your preferred hardware is in stock and quick to ship; otherwise, you may face a long lead time and minimum purchase requirements.

We recommend these vendors for obtaining non-custom hardware without extensive wait times:

Hack #4 Time-consuming welding services

The Approved Sheet Metal team offers in-house welding, but certain welding services are faster than others. The type of welding you request will impact your lead time. For example, consider whether you really need TIG welding (a cleaner yet slower process) or if MIG welding will do the trick (not as neat, but very fast)!

Simple Solutions for Fast Parts from Approved Sheet Metal

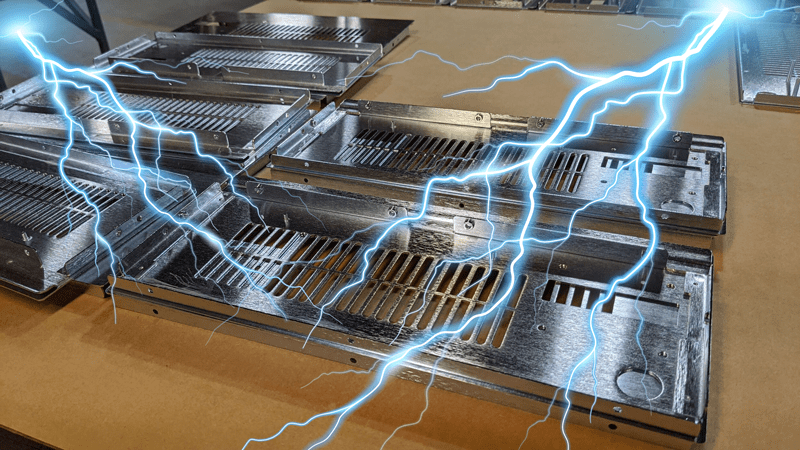

When you need the shortest possible turnaround time, ASM offers same-day shipping for flat, laser-cut parts! These rapid sheet metal parts are available in a wide selection of aluminum, galvanneal, galvanized, steel, and stainless materials. Simply submit your order by 10 a.m., and you’ll have your parts in no time.

Even our standard lead times are shorter than average, with most low-volume productions of up to 5,000 sheet metal parts possible in as little as two weeks.

Our custom fabrication shop is here for you no matter what you need. Request a quote to get your next project moving forward!

How to Shrink Precision Sheet Metal Fabrication Lead Times FAQ

While in-house finishing services like powder coating have shorter lead times, external finishing services might take longer. Custom colors or complex finishes often require sourcing materials that can extend lead times. Opting for standard finishes can expedite the process.

Hardware insertion is a relatively quick process, provided the preferred hardware is readily available. Researching and selecting hardware in stock with quick shipping can prevent delays and minimum purchase requirements, expediting the lead time for your parts.

While our team offers in-house welding, the type of welding requested impacts lead times. For instance, TIG welding, though cleaner, can be slower compared to faster alternatives like MIG welding. Considering the welding method required can help optimize lead times for your parts.