Last updated on June 25th, 2024 at 10:00 am

Part designers have one goal: to produce a Class A prototype in the shortest amount of time possible. As sheet metal fabricators, we use the phrase “another day, another thousand dollars.” The longer your part takes on the shop floor, the more time and money are spent on set up, machining, and reworking.

To avoid racking up a hefty sum on your invoice, the key is to make your design as close to the end product as possible. What should you be watching out for in your sheet metal design file? Here’s our list—make sure to check it twice. 😉

Table of Contents

- 1 Top 5 Things to Check in Your Sheet Metal Design File

- 2 Recommended Default Sheet Metal Tolerances

- 3 Sheet Metal Design File FAQ

- 3.0.1 Why is it important to check the material thickness in my sheet metal design file?

- 3.0.2 What is tolerance, and why should I consider it in my sheet metal design?

- 3.0.3 Should I customize inside radii in my sheet metal design?

- 3.0.4 Why is it recommended to leave some wiggle room in overlapping parts of a design?

- 3.0.5 How can I avoid complications related to welding in my sheet metal design?

Top 5 Things to Check in Your Sheet Metal Design File

- Material thickness. Not all manufacturers carry standard material gauges in their shops, and suppliers can take 3-4 days to fulfill an order for a specific material thickness. If your prototype is modeled at a material thickness that is nonstandard (or doesn’t even exist!), you could waste time looking for material or redoing your design to match what’s available. Do yourself a favor and ask your manufacturer what materials they carry before you start sketching.

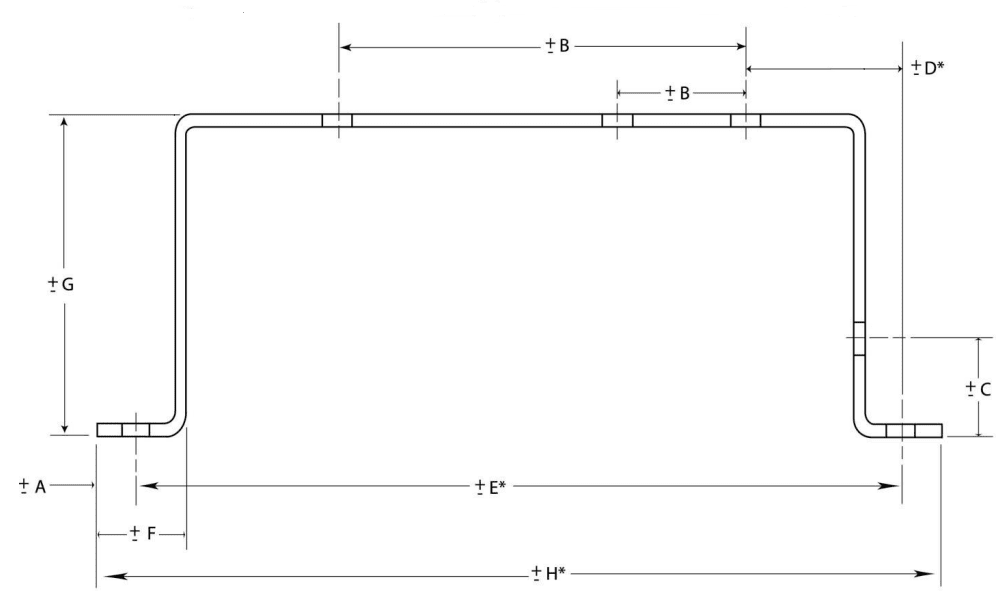

- Tolerance. Powder-coating or painting your part? Include additional tolerance for the finishing layer. It pays to be precise.

- Inside radius. Most shops use standard tooling to achieve common inside radii. Instead of customizing these dimensions for your design, stick to standard measurements. You’ll make your manufacturer’s life much easier. (Pro tip: Whenever possible, put a maximum radii on your part so tooling won’t be a problem!)

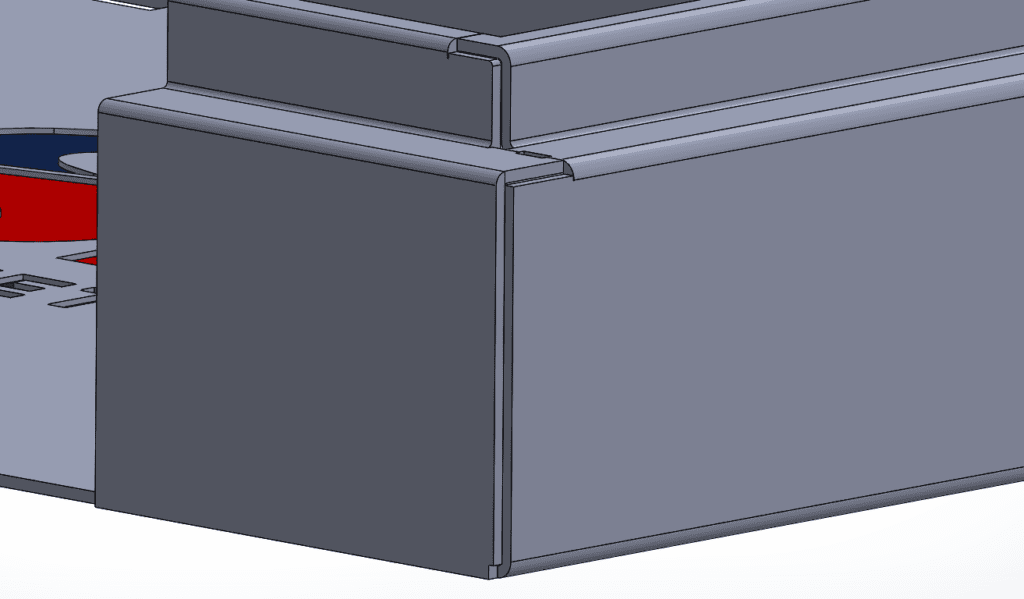

- Overlapping parts. When creating two parts that are designed to fit into each other (e.g. a box with a lid), don’t aim for a snug fit. Life isn’t perfect, so leave a little wiggle room in case you need to accommodate bowing in the material. #wiggleroom

- Welding. Welding can cause complications like material shrinkage and cracking that may affect budget and lead time. The best way to avoid this headache? Tell your manufacturer ahead of time if your part needs to be welded. The same goes for notching and tabbing: inform your manufacturer so they can create a game plan on how to address issues that might arise.

Get your part done faster by checking your sheet metal design file before you submit it to your fabricator. If you’re unsure how your design might affect the manufacturing process, don’t hesitate to give us a call. We’re always happy to share advice from the shop floor.

Need quick turn sheet metal fabrication services? Give us a shot on your next project!

Sheet Metal Design File FAQ

Checking material thickness is crucial because not all manufacturers carry standard material gauges. Using nonstandard thicknesses can lead to delays and added costs. It's wise to consult your manufacturer to ensure your design matches available materials.

Tolerance refers to the permissible variation in dimensions. When powder-coating or painting your part, it's essential to include additional tolerance for the finishing layer. Being precise in your design can save time and ensure the desired quality.

It's generally advisable to stick to standard inside radii measurements, as most shops use standard tooling for these. By doing so, you make the manufacturing process more straightforward. To avoid tooling issues, consider specifying maximum radii when possible.

Life isn't perfect, and materials may exhibit variations. When creating parts that fit into each other (e.g., a box with a lid), it's wise to leave a little wiggle room. This flexibility can help accommodate any bowing in the material, ensuring a better fit.

To avoid welding-related issues such as material shrinkage and cracking that can impact your budget and lead time, communicate with your manufacturer in advance if your part needs welding. Similar considerations apply to notching and tabbing. Inform your manufacturer so they can plan how to address potential issues effectively.