Last updated on January 27th, 2025 at 09:50 am

Let’s talk louvers.

These press-formed features are commonly found in applications that require airflow and light penetration:

- In closets, louvers improve airflow to prevent musty odors

- In microwaves, louvers release the heat generated when you cook food

- In window blinds, louvers allow you to filter adjustable quantities of light into a room

If you need a louver for your part, Approved Sheet Metal can make it for you. Here’s a brief recap on the common types of louvers and reasons for designing them into your product.

Table of Contents

Common Types of Louvers

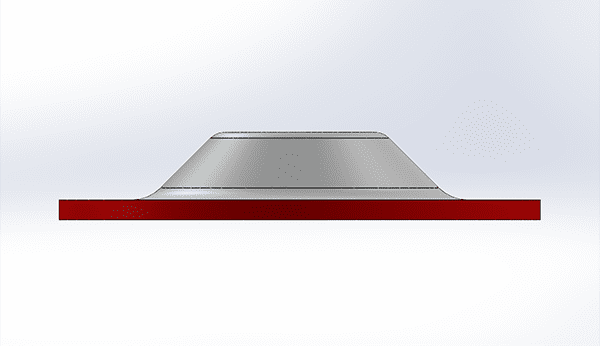

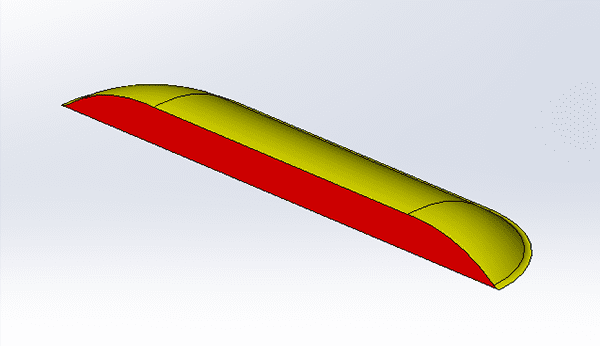

The most common louvers consist of a single-stroke form created in a turret punch press or press brake. This type of form sports a uniform radius, from the maximum height and length of the front opening to the smooth transition width on the flat surface of the sheet metal itself.

If a simple opening with a less complex metal flange is sufficient, a progressive louver tool can produce the desired airflow with a much lower profile radius. The tool progresses along the length of the sheet metal at .030 interval hits, creating louvers that are beautifully formed but not as smooth as the single-stroke form.

Why Design a Louver Into Your Product?

Though louvers are used for various applications (e.g. downspouts, gutters, vents, windows), their primary function is simple: providing proper airflow.

In buildings, louver systems facilitate air intake and exhaust to ensure good air quality for inhabitants. Louvers in products like microwaves act as a cooling system. When incorporated into designs for outdoor applications, louvers can effectively deter debris and protect against harsh weather elements. In some industrial applications, a louver will serve as a helpful location indicator for welding and other operations that occur on the manufacturing floor.

Does your part need to “breathe?” It probably needs a louver!

Aesthetic Considerations

Louvers are not just functional—they can also enhance the visual appeal of your product. In addition to their practical benefits, thoughtfully designed louvers add character and a polished appearance, particularly in consumer-facing applications like furniture, electronics, or architectural structures.

Here are a few ways aesthetics play a role in louver design:

- Shape Variations: Louvers can be formed in various shapes, including rounded, rectangular, and trapezoidal designs, to complement the overall design of your product.

- Material Finish: Choose from brushed, polished, or coated finishes to align with your product’s visual style while enhancing durability.

- Seamless Integration: Properly placed louvers can maintain a sleek, cohesive look without interrupting the design flow of your part or product.

- Color Options: Powder coating or anodizing can provide additional customization, ensuring the louvers match your brand or aesthetic preferences.

- Decorative Applications: In some cases, louvers are used solely for their visual impact, creating a modern, industrial look while maintaining functionality.

Cost and Efficiency Benefits

Designing with louvers can also help reduce costs and improve manufacturing efficiency, making them a smart choice for many applications.

- Standard Tooling Options: Utilizing our library of standard louver tools and dimensions can save thousands of dollars on custom tooling costs. Our pre-existing options cover a wide range of common requirements, reducing lead times and expenses.

- Efficient Production Processes: Our advanced press brake equipment ensures precise, consistent louvers with minimal setup time. This allows for faster production runs and reduced labor costs.

- Material Optimization: By designing louvers to align with material strengths and thicknesses, you can minimize waste and improve material utilization.

- Energy Efficiency in Products: Louvers improve airflow, potentially reducing the need for additional cooling or ventilation components, lowering your product's overall cost.

- Durable and Long-Lasting: With materials like aluminum, stainless steel, and cold-rolled steel, our louvers are designed to withstand wear and environmental stress, reducing long-term maintenance costs.

SOLIDWORKS Tech Tip #4: Louvers and Max Height

Let Approved Sheet Metal Make a Louver for Your Part

When your sheet metal application requires a louver, Approved Sheet Metal is here to make it for you. Simply tell us the height and size of the requested louver and we’ll custom-make it to meet your specific requirements and material thicknesses. We can form aluminum and cold roll steel louvers ranging from .47” to .119” thick and stainless steel louvers up to 0.60” thick.

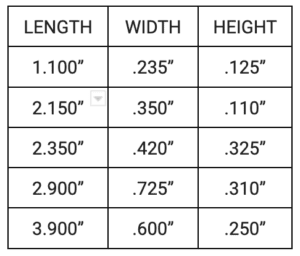

For your convenience, we have a list of standard louver tools and dimensions (though keep in mind that height dimensions will vary with material thickness and type). Designing a louver in accordance with our tools and dimensions can save you thousands of dollars on tooling alone!

Sheet Metal Louver Design FAQ

Louvers are press-formed features commonly used in applications that require airflow and light penetration. They are commonly used in closets to improve airflow and prevent musty odors, in microwaves to release heat generated when cooking food, and in window blinds to filter adjustable quantities of light into a room.

The most common types of louvers consist of a single-stroke form created in a turret punch press or press brake. Another type of louver is produced by a progressive louver tool that can create the desired airflow with a lower profile radius.

The primary function of louvers is to provide proper airflow. They are used in buildings to facilitate air intake and exhaust to ensure good air quality for inhabitants. In outdoor applications, louvers can effectively deter debris and protect against harsh weather elements.

Approved Sheet Metal can custom-make a louver for your specific requirements and material thicknesses. We can form aluminum and cold roll steel louvers ranging from .47” to .119” thick and stainless steel louvers up to 0.60” thick. We also have a list of standard louver tools and dimensions that can save you thousands of dollars on tooling alone.

You can visit and fill out our online form to request a quote for a sheet metal part with louvers. We will then custom-make the louvers to meet your requirements and material thicknesses. We also have a list of standard louver tools and dimensions that can save you thousands of dollars on tooling