Last updated on February 23rd, 2024 at 08:42 am

What do table legs, tubular frames for medical equipment infrastructure, and aluminum tubes for structural aerospace frames have in common? Tube laser cutting, of course!

Tube laser cutting is precisely what it sounds like: the technique for cutting tubes and other structural shapes. It’s also used to cut holes or more complex shapes into the tube itself.

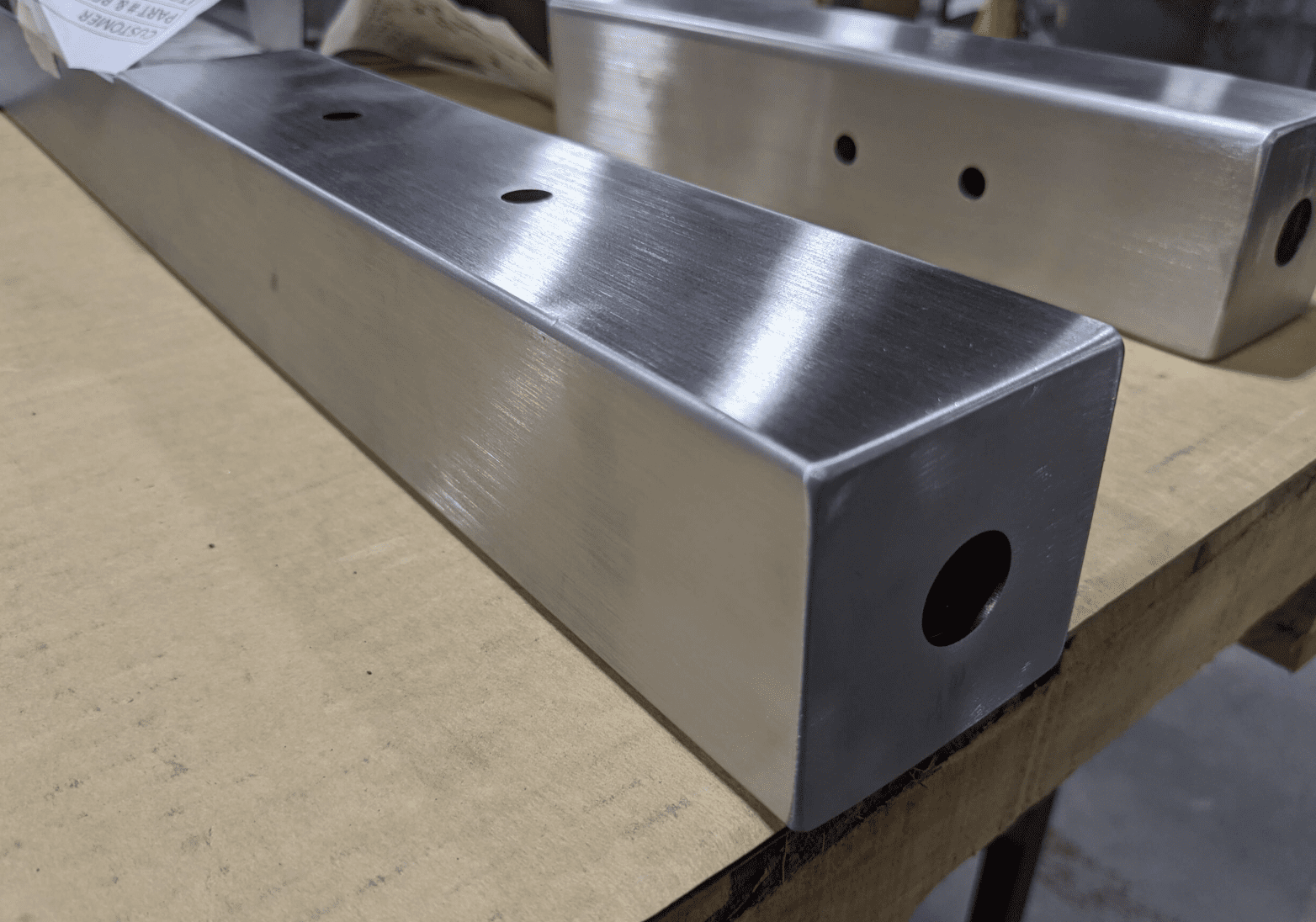

At Approved Sheet Metal, we provide precision tube laser cutting capabilities in-house at our metal fabrication shop so you can get parts delivered quickly. How quickly? We can ship parts as fast as the same day!

And all while maintaining exceptional quality. We routinely achieve tolerances of ± 0.003" on tube laser cut parts. Our laser operators have 15+ experience in laser cutting prototypes and low-volume production quantities.

Table of Contents

- 1 Why Tube Laser Cutting?

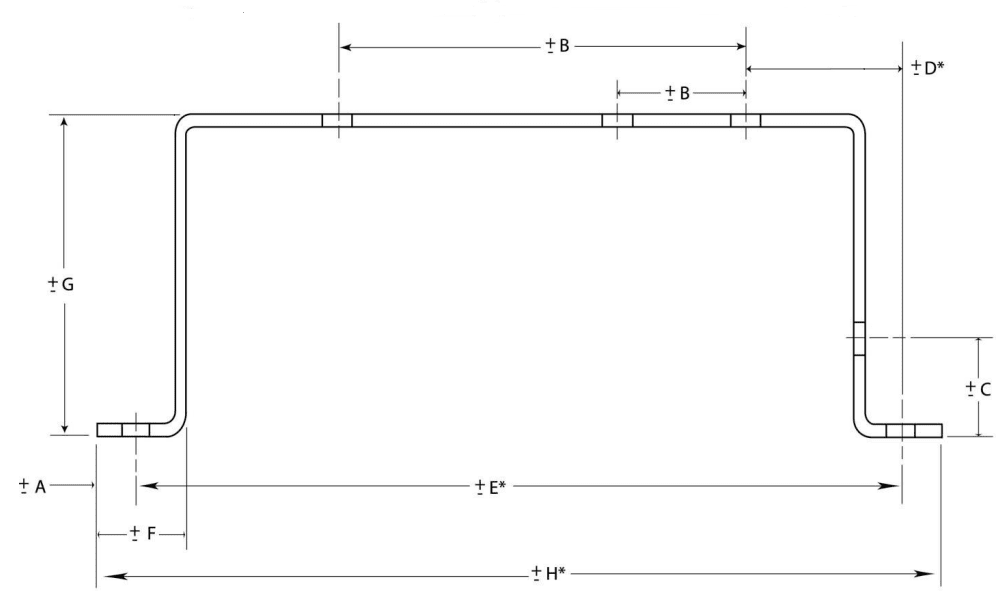

- 2 Recommended Default Sheet Metal Tolerances

- 3 Tube Laser Cutting FAQ

- 3.0.1 What exactly is tube laser cutting, and how does it benefit projects?

- 3.0.2 What are the advantages of tube laser cutting over CNC machining or manual cutting?

- 3.0.3 What industries commonly utilize tube laser cutting services?

- 3.0.4 What materials are suitable for tube laser cutting at Approved Sheet Metal?

- 3.0.5 What size considerations and capabilities does Approved Sheet Metal offer for tube laser cutting?

Why Tube Laser Cutting?

There are two alternatives to tube laser cutting—CNC machining and manually cutting the tube with a saw. But both methods have notable drawbacks.

The largest CNC machines can typically cut materials up to 5’ in length, which is great unless your project requires a longer tube. Our in-house tube laser cutting equipment can accommodate longer pieces of material easily.

Manually cutting tubes might be feasible but increases the risk of human error, inaccuracies, and tolerance issues. In contrast, tube laser cutting is an automated process that is much faster and allows for better repeatability.

Industry Applications for Tube Laser Cutting

Metal tubes are used widely around the globe in consumer goods and industrial applications. We commonly leverage tube laser cutting for these industries and applications:

Medical: stainless steel tubular frames, custom carts, and more

Aerospace: 6061 aluminum tubes for structural frames

Industrial and consumer: hand railings, awnings, machine guards, table legs, architectural designs, and much more

Materials Best Suited for Tube Laser Cutting

Tubes are made out of many different materials. We have the equipment and skills to cut materials such as:

- Steel

- Stainless steel

- Galvanized steel

- Aluminum

- Black pipe

- Chrome alloy

- Any electrically conductive material

Size Considerations for Tube Laser Cutting

It’s important to consider each material's thickness, length, and weight. Here’s what we can handle at our metal fabrication shop:

- Materials measuring up to 24’ in length

- Materials weighing up to 400 pounds

- Material thicknesses ranging from 1/32" to 5/8"

We can work with an array of shapes in various sizes:

- Round: 0.75" to 6”

- Square: 1" to 6"

- Rectangle: 1" to 6"

- Angle: 1" to 6"

- Channel: 1" to 6"

Approved Sheet Metal is proud to provide expert tube laser cutting services. While most sheet metal fabrication shops can cut and drill metal, our team takes tube laser cutting to the next level. Our customers appreciate our attention to detail and commitment to excellence.

We have the skills, knowledge, and expertise to get your project done right the first time, saving you time and money while keeping stress out of the equation. You can trust our team to exceed your expectations.

Give us a shot on your next tube laser cutting project—request a quote to get started.

Tube Laser Cutting FAQ

Tube laser cutting is a precise method used for cutting tubes and structural shapes, enabling the creation of holes or intricate shapes within the tube itself. This process is beneficial as it's fast, automated, and maintains exceptional quality. At Approved Sheet Metal, our in-house capabilities allow for rapid part delivery, sometimes even shipping parts the same day.

While CNC machining and manual cutting with saws are alternatives, they come with limitations. CNC machines have length restrictions, whereas manual cutting poses risks of human error and tolerance issues. Tube laser cutting offers automation, speed, better repeatability, and the ability to handle longer pieces of material, surpassing the limitations of other methods.

Tube laser cutting finds extensive use across various industries, including:

- Medical: Creating stainless steel tubular frames and custom carts.

- Aerospace: Fabricating 6061 aluminum tubes for structural frames.

- Industrial and Consumer: Crafting hand railings, awnings, machine guards, table legs, architectural designs, and more.

Our equipment and expertise allow us to effectively cut a range of materials, including steel, stainless steel, galvanized steel, aluminum, black pipe, chrome alloy, and any electrically conductive material, ensuring flexibility and versatility for diverse project needs.

At our metal fabrication shop, we can handle various material sizes:

- Lengths up to 24 feet

- Weights up to 400 pounds

- Thicknesses ranging from 1/32" to 5/8" Additionally, we work with different shapes such as round, square, rectangle, angle, and channel within specific size ranges, providing comprehensive cutting options to suit project requirements.