Last updated on January 13th, 2025 at 12:08 pm

At Approved Sheet Metal, we find that welding sheet metal is one of the most misunderstood processes in precision sheet metal fabrication. In an effort to demystify welding and help our customers choose the optimal welding method for a part, we do our best to clearly outline the benefits and limitations of different custom welding techniques.

Here, we’ll explore the sheet metal welding methods we use in our shop and explain what to expect from each one.

Table of Contents

- 1 Spot Welding

- 2 Tack Welding

- 3 Fuse Welding

- 4 Stitch Welding

- 5 Plug Welding

- 6 Seam/Fillet Welding

- 7 MIG Welding

- 8 TIG Welding

- 9 Weld Strength and Durability

- 10 Heat Affected Zone (HAZ)

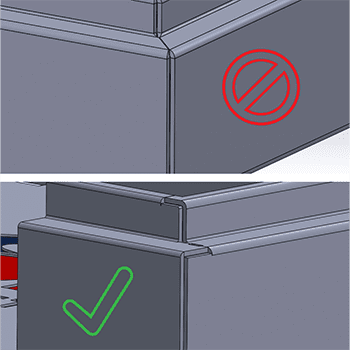

- 11 Sheet Metal Part Design for Manufacturing Tip

- 12 Sheet Metal Fabrication Welding FAQ

- 12.0.1 What are the key welding methods used by fabricators?

- 12.0.2 What is the difference between spot welding and tack welding?

- 12.0.3 When should fuse welding be used, and what materials are best suited for it?

- 12.0.4 What is the purpose of stitch welding, and in what scenarios is it ideal?

- 12.0.5 When is MIG welding preferred over other welding methods, and what should be considered when choosing MIG welding?

Spot Welding

Also known as resistance welding, spot welding involves compressing two pieces of sheet metal and applying pressure and heat from copper electrodes to create a nugget of weld that connects the pieces.

Spot welding is often confused with tack welding, which also uses a small amount of weld to attach two pieces. However, unlike tack welding, spot welding creates a permanent weld.

Considerations for spot welding

- Requires unique tooling and fixturing

- Welds are structurally sound but not watertight

- Limited to certain material thicknesses and part geometries

- Achieves a Class A finish without the need for grinding

- Can be just as strong as seam weldments

- Ideal for creating hat channels

- The fastest and most cost-effective welding option for high-volume projects

- Requires strategic placement to ensure proper part function

Tack Welding

Tack welding is a low-heat, typically temporary welding process that holds sheet metal pieces together in proper alignment until they can be permanently welded.

Considerations for tack welding

- An inexpensive method for fastening two parts when a high-quality weld is not required

- Not a good fit for structural applications

- Welds are not watertight

Fuse Welding

Fuse welding, also known as fusion welding, is achieved by heating two surfaces to the point where they melt together, with or without a filler rod.

Considerations for fuse welding

- Typically used on steel or stainless steel parts

- Can create watertight welds

- While not a cosmetic weld, it can be done very fine and requires little to no cleanup

Stitch Welding

Stitch welding, also called intermittent or step welding, involves applying short, spaced sections of weld (1”–2”) along a connection point between two parts, giving the appearance of stitches. We typically use a filler rod with this method.

Considerations for stitch welding

- Ideal for when a fully welded seam or connection point is not required

- Welds are not watertight due to gaps between the weld “stitches”

- Low risk of part deformation due to minimal heat generated

- Less expensive than welding an entire seam

Plug Welding

Plug welding is a method in which a round hole or slot is filled with a puddle of weld that is used to mate two parts or surfaces together. Plug welding has many drawbacks and isn’t a popular choice.

Considerations for plug welding

- Time-consuming and difficult to clean

- High risk of deformation due to the amount of heat required

- Welds are not watertight

Seam/Fillet Welding

Seam welding, or fillet welding, is one of the most common methods we use at Approved Sheet Metal. This arc welding method uses a filler rod to create a continuous weld across the entire seam of the pieces being joined.

Considerations for seam/fillet welding

- Creates a strong, watertight seal

- Prone to deformation, depending on the material thickness and length of the seam

- Requires the most cleanup of any welding method

MIG Welding

Metal inert gas (MIG) welding is an arc welding method typically used on large parts made of thick material, such as structural steel parts. With this method, we feed a continuous solid wire electrode through a welding gun into a weld pool to join two pieces together.

Considerations for MIG welding

- Faster than other arc welding methods, such as TIG welding

- Can create watertight seals

- Not as clean a weld as TIG welds, so not ideal for precision parts

TIG Welding

We frequently use tungsten inert gas (TIG) welding at ASM because it is an excellent method for precision parts. This arc welding technique uses non-consumable tungsten that can be supplemented with filler metal added by hand.

Considerations for TIG welding

- Produces high-quality, strong, clean welds

- Slower and more expensive than other methods

- One of the most common welding methods

Weld Strength and Durability

Weld strength and durability are key factors in determining the suitability of a welding method for a given application. The strength of a weld affects the overall integrity and reliability of the finished part, especially in high-stress or structural applications. Here's how various welding techniques compare:

- Spot Welding: While spot welding creates a structurally sound connection, it is not ideal for high-stress applications where strength is a critical factor. The welds are strong but may not be as durable over time as continuous welds. It is best used in non-structural parts or where the connection is not subjected to heavy loads.

- Tack Welding: Typically used as a temporary solution, tack welding doesn’t provide long-term strength or durability. It holds parts in place until they are permanently welded but is not suitable for structural strength.

- Fuse Welding: Fuse welding can provide strong, watertight joints, but the durability depends on factors like material compatibility and the precision of the weld. It is generally stronger than tack welding but can be prone to weaknesses if not executed correctly.

- Stitch Welding: While stitch welding provides a good balance of strength and cost-effectiveness, it’s not as strong as a continuous seam weld. The gaps between the stitches can weaken the overall bond, making it less durable for applications under high stress or heavy load.

- Plug Welding: Plug welds can be strong, but they often face issues with strength and durability due to their limited surface area. The heat required to create the weld can also cause distortion in surrounding materials, which may impact the overall durability of the weld.

- Seam/Fillet Welding: Seam welding creates one of the strongest and most durable welds due to the continuous bond it forms. It’s highly resistant to stress and provides a watertight seal, making it ideal for applications that demand strength and long-term durability.

- MIG and TIG Welding: Both MIG and TIG welding provide strong and durable welds, but TIG welding is typically more precise and creates cleaner, stronger joints, especially for thin-walled components. MIG welding is faster but may not offer the same level of durability as TIG in precision parts.

Heat Affected Zone (HAZ)

The Heat Affected Zone (HAZ) is an area around the weld that has been altered by the heat generated during the welding process. This region can affect the properties of the material, including strength, hardness, and corrosion resistance. The size and impact of the HAZ vary depending on the welding method used:

- Spot Welding: Spot welding creates a localized HAZ, usually minimal in size, around the nugget. The impact on material properties is less significant, but excessive heat could cause changes in the surrounding metal’s strength or resistance to fatigue.

- Tack Welding: The HAZ from tack welding is typically small and doesn’t significantly affect material properties. However, because tack welding is done in a low-heat, quick process, the overall impact on the base metal is limited.

- Fuse Welding: Fuse welding can produce a larger HAZ, particularly if the heat input is not controlled carefully. This can affect the material’s hardness and make it more susceptible to stress or cracking in some cases.

- Stitch Welding: The heat input for stitch welding is low, so the HAZ is minimal and doesn’t usually affect the overall material strength. However, excessive heat from longer welds could cause some deformation or undesirable changes in the surrounding metal.

- Plug Welding: Due to the localized heat required to fill the hole with weld, plug welding can result in a significant HAZ. This can cause distortion, particularly in thinner materials, and lead to possible strength degradation in certain applications.

- Seam/Fillet Welding: The HAZ from seam welding is generally moderate to large, especially for long seams. The heat affects the entire weld zone and may alter the mechanical properties of the material, requiring post-weld heat treatment to relieve stress or restore strength.

- MIG and TIG Welding: MIG and TIG welding create moderate to large HAZs depending on the material and welding parameters. The HAZ can affect the overall strength, making it essential to carefully control the heat input. TIG welding generally results in a smaller HAZ due to the more focused heat source, preserving the base material’s integrity.

Applications and Best Use Cases

Each welding method has distinct advantages, making them more suitable for certain applications than others. Understanding these best-use scenarios is crucial to choosing the optimal welding technique for a project:

- Spot Welding: Ideal for high-volume production runs where speed and cost-effectiveness are important. It is commonly used in industries such as automotive manufacturing for joining sheet metal parts. Best for creating non-load-bearing connections in thin materials.

- Tack Welding: Often used in the early stages of fabrication to hold parts in alignment for further welding. It’s best for temporary fixes and is used in almost every welding process as part of the initial assembly phase.

- Fuse Welding: Typically used for joining steel or stainless steel in applications where strength and the ability to create watertight seals are important, such as in piping or tanks. Best used for projects that require a fusion of parts without filler metal.

- Stitch Welding: A cost-effective method for less critical applications where a continuous weld isn’t necessary. Often used in automotive or appliance manufacturing for joining parts that don’t require a high level of strength but still need to be held together securely.

- Plug Welding: Best used when you need to join parts together through a pre-drilled hole or slot. It’s commonly used in automotive and appliance industries to attach two parts that cannot be welded directly to one another.

- Seam/Fillet Welding: Ideal for creating strong, watertight seals, especially in pressure vessels, pipes, or tanks. It’s commonly used in industries like HVAC, water treatment, and construction where joints need to withstand pressure or exposure to the elements.

- MIG Welding: Best suited for thicker materials and large parts, such as structural steel or construction components. MIG welding is commonly used in manufacturing, heavy equipment, and automotive industries for fast, efficient production of durable parts.

- TIG Welding: The go-to method for precision applications, especially for thin materials or intricate parts. It’s used in industries like aerospace, medical device manufacturing, and custom metal fabrication, where high-quality, clean welds are essential. Ideal for stainless steel, aluminum, and other non-ferrous materials.

At Approved Sheet Metal, we know that providing exceptional welding services is part of being a sheet metal manufacturing partner you can trust. Request a quote to see the ASM difference today!

Sheet Metal Fabrication Welding FAQ

Fab shops typically employ several welding methods, including spot welding, tack welding, fuse welding, stitch welding, plug welding, seam/fillet welding, MIG welding, and TIG welding, each with unique applications and characteristics.

Spot welding creates a permanent weld by compressing two pieces of sheet metal with copper electrodes, while tack welding is a low-heat, temporary method used to temporarily hold metal pieces in alignment before permanent welding. Spot welding is structurally sound and ideal for high-volume projects, while tack welding is cost-effective but not suitable for structural applications.

Fuse welding is primarily used on steel or stainless steel parts to create watertight welds. It involves heating two surfaces until they melt together, and it can be done finely with minimal cleanup, making it suitable for specific applications.

Stitch welding is employed when a fully welded seam or connection point is not required. It involves applying short, spaced sections of weld along a connection point, and while it's not watertight, it minimizes the risk of part deformation due to minimal heat generated. It's also a cost-effective alternative to welding entire seams.

MIG welding is typically used on large parts made of thick material, such as structural steel parts. It's faster than other arc welding methods and can create watertight seals. However, it may not be the best choice for precision parts due to its cleanliness. Consider the specific application and material when choosing MIG welding.