Last updated on February 6th, 2025 at 09:04 am

Approved Sheet Metal has the expertise and capabilities to make almost any precision sheet metal part our customers request. Sometimes we just have to think outside the box to devise a creative solution.

When it comes to sheet metal forming U-shaped parts, for instance, the maximum depth our press brake can form is 8”. If you need a U-shaped part with a height exceeding 8”, we’ll still deliver the part you need一we’ll simply take a slightly different approach.

Let’s explore our process for reviewing U-shaped part designs and how we overcome equipment constraints to satisfy our customers’ sheet metal forming needs.

Table of Contents

- 1 Common U-Shaped Parts

- 2 How We Process Requests for U-Shaped Parts

- 3 Cost & Lead Time Considerations

- 4 Sheet Metal Part Design for Manufacturing Tip

- 5 U-Shaped Sheet Metal Fabricated Parts FAQ

- 5.0.1 What should I do if the U-shaped part I need exceeds the maximum depth your press brake can form?

- 5.0.2 Are there any considerations to keep in mind if my part needs to be constructed from separate pieces?

- 5.0.3 How can I determine if reducing the height of my part to 8 inches or less is a viable option?

- 5.0.4 Will the fabrication process for my U-shaped part be compromised if it needs to be constructed from separate pieces?

- 5.0.5 How can Approved Sheet Metal assist with unique or challenging sheet metal fabrication needs?

Common U-Shaped Parts

Our precision sheet metal fabrication shop frequently fabricates U-shaped parts for our customers. Examples of these parts include:

- Boxes

- Brackets

- Covers

- Handles

- Enclosures

How We Process Requests for U-Shaped Parts

Forming countless U-shaped parts has helped us develop a foolproof process for ensuring that our customers are thrilled with the final product.

Determine part height

First, we check the height of the desired part, which tells us if we can form the part from a single piece of metal. If the part has a height of 8” or less, we’ll proceed with press brake forming. If the height exceeds 8”, we’ll initiate a conversation with you to discuss your options.

Consult with customer

If needed, we’ll let you know that due to your part’s dimensions, we’ll need to construct it from separate pieces, which our expert team will then weld together. To help you decide whether to proceed with this approach, we’ll share a few considerations:

- While this solution works well for many customers, the labor required to provide high-quality welding services does add to a part’s cost—sometimes a considerable amount.

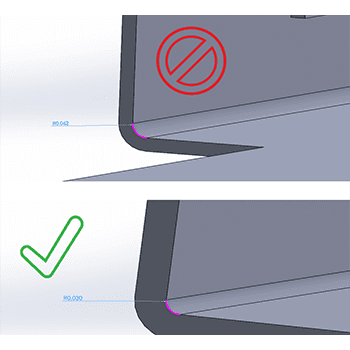

- Parts formed from a single piece of metal using a press brake are stronger than parts composed of separate pieces. If you can modify your design to lower the part’s height to 8” or less, you’ll get a stronger part for a lower cost.

- Unsure if your part will function as intended with a reduced height? Let us run your design through our SOLIDWORKS software! This cutting-edge program allows us to easily manipulate part dimensions to determine how a part will perform with various design modifications.

Cost & Lead Time Considerations

1. Single-Piece Formed vs. Welded Parts: Cost Breakdown

Forming a U-shaped part from a single piece of sheet metal is generally more cost-effective than welding multiple pieces. Here’s why:

| Factor | Single-Piece Formed (≤8” height) | Welded (Height >8”) |

|---|---|---|

| Material Cost | Lower – One continuous piece | Slightly higher – More material used |

| Labor Cost | Lower – Fewer manufacturing steps | Higher – Additional welding and finishing required |

| Tooling Cost | Minimal – Uses standard press brake tools | Minimal – Uses standard welding tools |

| Structural Integrity | Stronger – No weld seams | May require reinforcement |

| Aesthetic Quality | Uniform finish | May need additional grinding or polishing |

2. Impact on Lead Time

- Formed in One Piece: Faster production time since only bending operations are required.

- Welded Assembly: Adds extra time for welding, cooling, post-processing (e.g., grinding, finishing), and quality checks.

- Additional Finishing: If welding requires polishing or coating, factor in extra time for these processes.

3. How to Minimize Costs & Lead Time

- Modify Your Design: If possible, adjust the height to 8” or less to avoid welding and speed up production.

- Choose the Right Material: Select materials that weld easily if welding is necessary.

- Plan for Finishing Needs: Consider whether post-weld finishing (grinding, powder coating, etc.) is required to achieve your desired look and function.

Proceed with precision sheet metal fabrication

Once we collectively determine the ideal approach to fabricating your U-shaped part, we’ll begin the precision sheet metal fabrication process according to your preference. Regardless of our approach, you can rest assured that your part will be in good hands with our dedicated team.

Looking for a metal fabrication shop that excels at finding creative solutions to complex manufacturing challenges? Request a quote to work with our skilled team today!

U-Shaped Sheet Metal Fabricated Parts FAQ

If your U-shaped part height surpasses the 8-inch limit of our press brake, don't worry! We'll still craft the part you require using an alternative approach, typically involving the welding together of separate pieces to achieve the desired height.

Absolutely. While this method provides a solution for larger U-shaped parts, it involves additional labor for welding, which can affect the overall cost of the part. Additionally, parts formed from a single piece tend to have greater strength compared to those assembled from separate components.

If there's flexibility in the design, modifying the height to 8 inches or less allows for a stronger part at a potentially lower cost. We can assess this for you using SOLIDWORKS software, which enables us to simulate how different design modifications may impact the part's functionality.

Not at all. Regardless of the approach—whether forming from a single piece or assembling separate components—we ensure precision in the fabrication process. Our skilled team maintains quality standards to deliver a part that meets your specifications and requirements.

We specialize in thinking creatively to fulfill complex requests. If your project demands innovative solutions for U-shaped parts or any other precision sheet metal needs, our experienced team is ready to collaborate and deliver the solutions you require.