Table of Contents

- 1 Why You Need to Bring Your Manufacturer In During Part Design

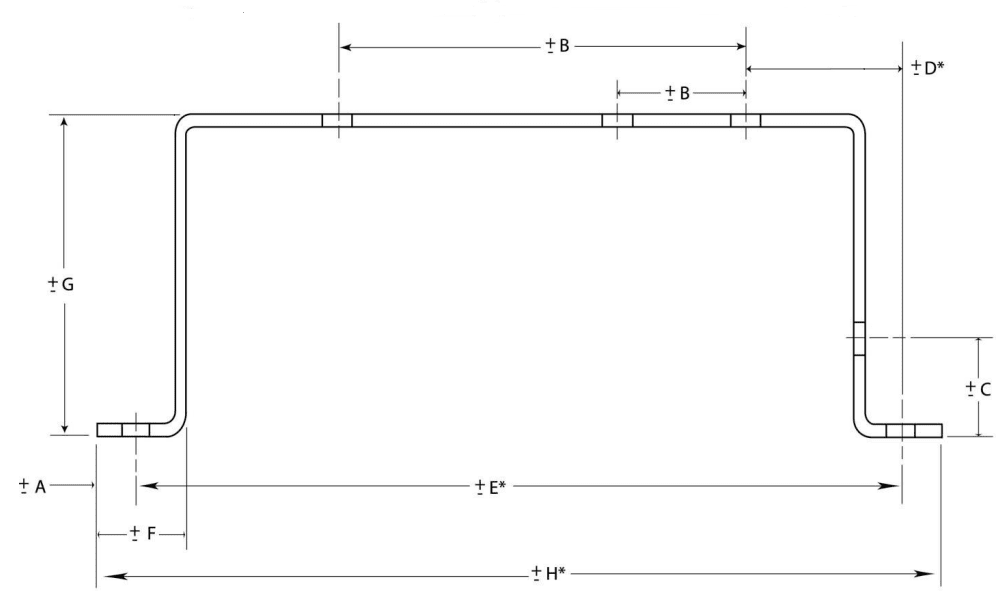

- 2 Recommended Default Sheet Metal Tolerances

- 3 Sheet Metal DFM FAQ

- 3.0.1 Why is Design for Manufacturability (DFM) important in sheet metal manufacturing?

- 3.0.2 How can involving a precision sheet metal shop early benefit part design?

- 3.0.3 What problems can arise when welding sheet metal parts?

- 3.0.4 How can interlocking tabs help solve welding-related issues?

- 3.0.5 What are some DOs and DON'Ts when working with a precision sheet metal shop?

Get your models to a sheet metal shop that gets it.

Last updated on April 12th, 2024 at 08:06 am

Most sheet metal manufacturers will tell you that in order to create a top-quality part, you need a smart design engineer who knows how to Design for Manufacturability (DFM). To optimize a part for production, the designer must take the following into consideration: material formability, machine capabilities, as well as overall lead time and cost. It can be a tricky process. But without proper design, you can waste time with change orders and reworks.

But I’ll let you into a trade secret. If you want top-quality parts with a quick turnaround, understanding DFM isn’t enough.

If you’re a design engineer, I’m sorry to say this, but a manufacturer will rarely use the flat pattern you spent so much time on. What you need to do is simple: get your CAD models to a precision sheet metal shop as early as you can.

Why You Need to Bring Your Manufacturer In During Part Design

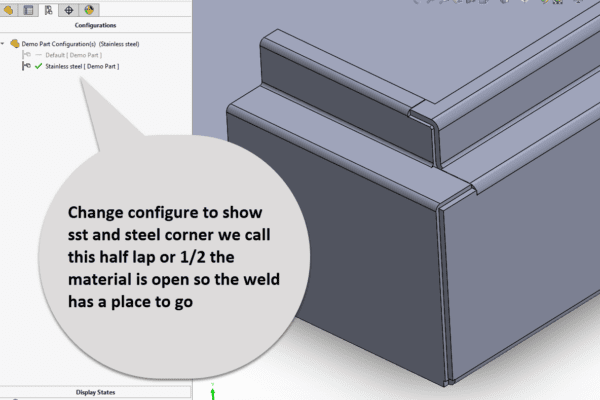

Precision sheet metal shops know the ins and outs of their machines. They know that a .047\" stainless steel will heat distort from welding but a .074\" will hold its shape, and that a .25 alum won’t bend the way you want it to without a large radii. Your sheet metal fabricator needs a little wiggle room to make the best decisions for your job, both in terms of materials and approach.

Case Study: Interlocking Tabs

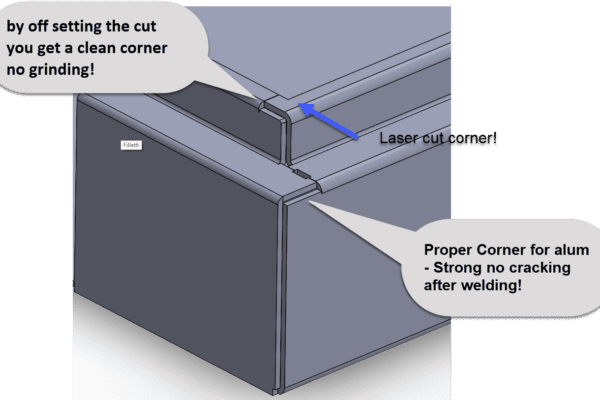

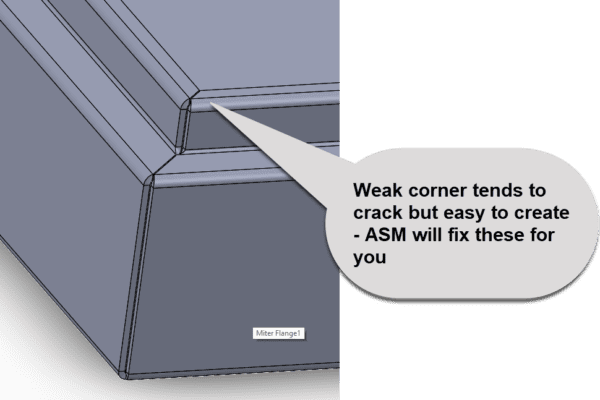

Welding is a good example of a situation where it’s best to talk to your sheet metal shop early on about your design. Welding can create complications that drive up your cost and lead time:

- Material shrinkage when welding

- The need for complex fixtures to hold parts together

- A go/no go inspection process

- Parts welded backwards

- Measuring and hammering parts back to tolerance

- Corner gaps larger than .002 that the welder will need to fill

- Cracking!

As it turns out, all of those problems above can actually be solved by adding interlocking tabs to hold your part in place and make it stronger. Plus, your local sheet metal shop should be able to advise you on how many tabs you need, tab width vs. material thickness, gap size, etc.

Ready to start working with your precision sheet metal shop? Here are some DOs and DON’Ts to get you started:

| DO | DON'T |

|---|---|

| ✅ Keep your parts a uniform thickness. This is crucial to al surrounding parts. Check out our list os standard thicknesses here | ❌ Spend time unfolding parts. It's not always the best way to fabricate. When prototyping, split a complex part into multiple parts to shorten lead time. |

| ✅ Include hardware | ❌ Cut or tab corners. Manufacturers tend to take shortcuts when you cut and tab for them |

| ✅ Add .005 to .0015 gaps for all connecting parts | ❌ Start with a solid shell. You'll lose time converting an assembly back to a solid shell |

If your manufacturer won’t walk through the design process with you, we gladly will! Contact us today and let’s get your design ready for the shop floor!

Sheet Metal DFM FAQ

DFM ensures that a part is optimized for production by considering factors like material formability, machine capabilities, lead time, and cost. It prevents issues like change orders and reworks, leading to higher quality parts.

Precision sheet metal shops possess expertise in machine operations and materials. Involving them early allows them to provide insights and make informed decisions about aspects like material selection, tolerances, and approach, which can improve the overall outcome.

Welding can lead to issues such as material shrinkage, complex fixture requirements, inspection challenges, backwards assembly, parts out of tolerance, corner gaps, and even cracking. These problems can drive up costs and lead times.

Interlocking tabs can hold parts in place, enhance strength, and mitigate welding complications. They address problems like material shrinkage, gaps, and assembly misalignment, improving the overall welding process.

- DO: Keep parts uniform in thickness for consistency.

- DO: Include necessary hardware in your design.

- DO: Provide appropriate gaps (e.g., .005 to .0015) for connecting parts.

- DON'T: Spend excessive time unfolding parts; consider splitting complex parts.

- DON'T: Cut or tab corners in a way that could compromise manufacturing.

- DON'T: Start with a solid shell; it's more efficient to begin with an assembly.

Remember, if your manufacturer isn't guiding you through the design process, our experts are here to help. Contact us to prepare your design for efficient manufacturing on the shop floor!