Last updated on January 14th, 2025 at 08:06 am

As a leading sheet metal fabricator, Approved Sheet Metal knows the importance of high-quality precision welding.

Our welders are skilled in a wide range of techniques and can help customers determine the ideal assembly strategy for their parts. Selecting the appropriate weld joint type is a key step in this process.

Table of Contents

- 1 Common Weld Joints in Custom Sheet Metal Fabrication

- 2 Consult Your Sheet Metal Fabricator about the Optimal Joining Method

- 3 Consult Your Sheet Metal Fabricator about the Optimal Joining Method

- 4 Sheet Metal Part Design for Manufacturing Tip

- 5 Sheet Metal Fabrication Weld Joints FAQ

- 5.0.1 What are the primary considerations when choosing between open and closed corner joints for welding?

- 5.0.2 Why might spot-welded flanges be more suitable for high-volume production than smaller runs?

- 5.0.3 How does Approved Sheet Metal decide the optimal joining method for a specific assembly?

- 5.0.4 Apart from welding, what alternative methods does ASM recommend for joining parts?

- 5.0.5 How does ASM ensure exceptional results in sheet metal assembly, regardless of the chosen joining solution?

Common Weld Joints in Custom Sheet Metal Fabrication

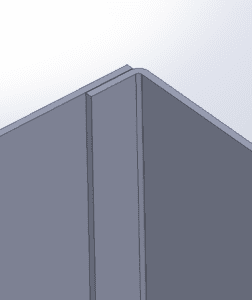

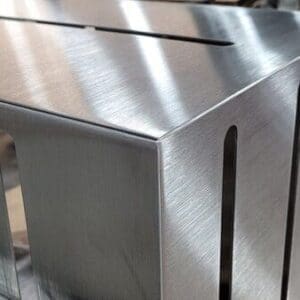

Open corner weld joint

In an open corner joint, two pieces are joined along one edge at a 90-degree angle but are not flush, leaving a V groove behind the joint. This “open corner” is then welded with a filler rod along the entire length of the joint.

Typically used on aluminum parts over 0.40” thick, open corner joints can be welded using several methods: fillet/seam, fuse, tack, or stitch welding. Our expert welders can determine the right approach based on the characteristics of the material and how much weld is needed to fill the open corner.

With this joint type, care must be taken to avoid heat deformation and warping.

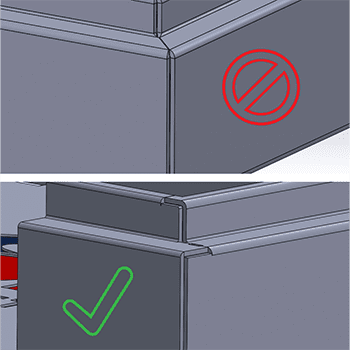

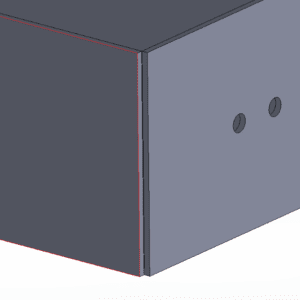

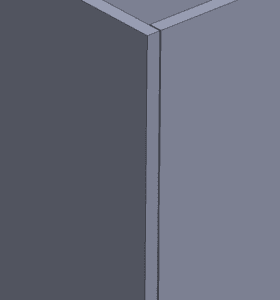

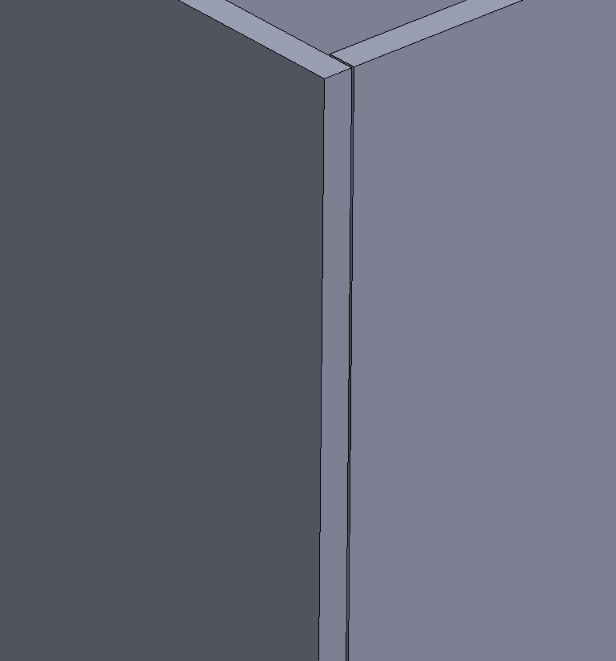

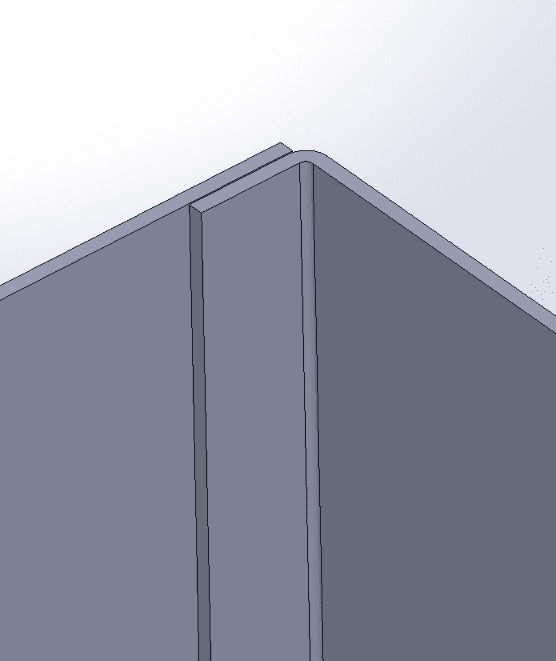

Closed corner weld joint

Like open corner joints, closed corner joints form a 90-degree angle, but in this case, the edges are flush against each other, leaving no gap. This joint type is also referred to as a square butt joint. Corner joints are typically fuse welded without a filler rod, although fillet/seam, tack, or stitch welding can also be used.

Like open corner joints, closed corner joints form a 90-degree angle, but in this case, the edges are flush against each other, leaving no gap. This joint type is also referred to as a square butt joint. Corner joints are typically fuse welded without a filler rod, although fillet/seam, tack, or stitch welding can also be used.

As with open corner joints, the primary challenge with closed corner joints is preventing heat deformation and warping.

Spot-Weld Flange Joint

Compatible with all sheet metal materials, spot-welded flanges can be welded insideor outside a part to create a joint between two pieces. Flanges must have a minimum width and length of 0.375”, although we recommend 0.500”.

Compatible with all sheet metal materials, spot-welded flanges can be welded insideor outside a part to create a joint between two pieces. Flanges must have a minimum width and length of 0.375”, although we recommend 0.500”.

Spot-welded flanges are a cost-effective, efficient solution for high-volume production but less optimal for smaller production runs because of the specialty tooling and fixturing required.

Consult Your Sheet Metal Fabricator about the Optimal Joining Method

ASM’s welders have decades of custom sheet metal fabrication experience and can work with you to determine the ideal joining method for your assembly—whether that means fabricating weld joints or using a different fastening method.

Joint and weld solutions

To determine the best weld for a joint, we’ll evaluate the length of the seam that needs to be welded as well as the material type and thickness.

If you call out a particular weld joint type and welding method, we’ll do our best to defer to your preference. However, if we identify a better solution for joining your parts, we may suggest an alternative approach.

For instance, say you have a 30” seam on an aluminum part, and you want it to be welded solid. We know from experience that the material would need to be very thick for it not to warp. If you’re using a thin material, we’ll likely recommend a stitch weld, which will hold the parts together just as well without generating a potentially damaging amount of heat.

Other joining solutions

Weld joints aren’t the only way to connect parts. In fact, in some cases, other joining methods can replace or supplement welding.

- Rivets. These mechanical metal fasteners create tight, semi-permanent joints that perform well in many applications. A benefit of using rivets is there is no need to worry about heat deformation.

- Tab and slot connectors. These connectors work well when a bracket needs to be welded onto the part. For a tab and slot assembly, we fabricate tabs on the bracket and slots on the part, which interlock like puzzle pieces. We then fill and grind the slots so they aren’t visible from the outside.

- Cleco fasteners. These small, bullet-shaped fasteners are inserted temporarily into holes drilled throughout the parts of an assembly, holding the parts in perfect alignment during welding. After welding is complete, we remove the clecos and fill the holes with weld for a polished finish.

Whichever joining solution your assembly requires, our experienced team is equipped to get the job done with exceptional results.

Request a quote for custom sheet metal fabrication services that will exceed your expectations!

Closed corner weld joint

Like open corner joints, closed corner joints form a 90-degree angle, but in this case, the edges are flush against each other, leaving no gap. This joint type is also referred to as a square butt joint. Corner joints are typically fuse welded without a filler rod, although fillet/seam, tack, or stitch welding can also be used.

Like open corner joints, closed corner joints form a 90-degree angle, but in this case, the edges are flush against each other, leaving no gap. This joint type is also referred to as a square butt joint. Corner joints are typically fuse welded without a filler rod, although fillet/seam, tack, or stitch welding can also be used.

As with open corner joints, the primary challenge with closed corner joints is preventing heat deformation and warping.

Spot-Weld Flange Joint

Compatible with all sheet metal materials, spot-welded flanges can be welded inside  or outside a part to create a joint between two pieces. Flanges must have a minimum width and length of 0.375”, although we recommend 0.500”.

or outside a part to create a joint between two pieces. Flanges must have a minimum width and length of 0.375”, although we recommend 0.500”.

Spot-welded flanges are a cost-effective, efficient solution for high-volume production but less optimal for smaller production runs because of the specialty tooling and fixturing required.

Consult Your Sheet Metal Fabricator about the Optimal Joining Method

ASM’s welders have decades of custom sheet metal fabrication experience and can work with you to determine the ideal joining method for your assembly—whether that means fabricating weld joints or using a different fastening method.

Joint and weld solutions

To determine the best weld for a joint, we’ll evaluate the length of the seam that needs to be welded as well as the material type and thickness.

If you call out a particular weld joint type and welding method, we’ll do our best to defer to your preference. However, if we identify a better solution for joining your parts, we may suggest an alternative approach.

For instance, say you have a 30” seam on an aluminum part, and you want it to be welded solid. We know from experience that the material would need to be very thick for it not to warp. If you’re using a thin material, we’ll likely recommend a stitch weld, which will hold the parts together just as well without generating a potentially damaging amount of heat.

Other joining solutions

Weld joints aren’t the only way to connect parts. In fact, in some cases, other joining methods can replace or supplement welding.

Rivets. These mechanical metal fasteners create tight, semi-permanent joints that perform well in many applications. A benefit of using rivets is there is no need to worry about heat deformation.

Rivets. These mechanical metal fasteners create tight, semi-permanent joints that perform well in many applications. A benefit of using rivets is there is no need to worry about heat deformation.- Tab and slot connectors. These connectors work well when a bracket needs to be welded onto the part. For a tab and slot assembly, we fabricate tabs on the bracket and slots on the part, which interlock like puzzle pieces. We then fill and grind the slots so they aren’t visible from the outside.

- Cleco fasteners. These small, bullet-shaped fasteners are inserted temporarily into holes drilled throughout the parts of an assembly, holding the parts in perfect alignment during welding. After welding is complete, we remove the clecos and fill the holes with weld for a polished finish.

Whichever joining solution your assembly requires, our experienced team is equipped to get the job done with exceptional results.

Material Considerations Beyond Thickness

When choosing the best weld joint type and welding method, material thickness is just one factor to consider. The type of material plays a critical role in determining weldability, strength, and overall performance. Here are some key material considerations:

Material Type and Its Impact

- Aluminum: Lightweight and corrosion-resistant, aluminum is commonly used in custom sheet metal fabrication. However, it has a low melting point, making it prone to warping and heat deformation. Our welders often use TIG welding for aluminum to achieve precise and clean results.

- Stainless Steel: Known for its durability and resistance to corrosion, stainless steel requires careful heat management to prevent discoloration or distortion. Spot welding and seam welding are often preferred for stainless steel assemblies.

- Mild Steel: Cost-effective and versatile, mild steel is easier to weld compared to other materials. Techniques such as MIG welding can be used for both speed and strength.

Surface Coatings and Treatments

- Anodized Aluminum: While anodizing enhances corrosion resistance, it creates a layer that must be removed in the weld area to ensure proper fusion.

- Galvanized Steel: The zinc coating on galvanized steel can release harmful fumes during welding. Adequate ventilation and preparation are crucial for safety and quality.

- Painted or Powder-Coated Materials: These coatings must be stripped from the weld zone to ensure strong, reliable joints.

Thermal Conductivity and Expansion

Materials with high thermal conductivity, like aluminum, require techniques that manage heat input to prevent issues like burn-through or uneven weld beads. Materials with high thermal expansion, like stainless steel, may need additional clamps or fixtures to maintain alignment during welding.

Alloy Compositions

Alloys often require specific filler materials and techniques to ensure compatibility and strength. For example, when welding dissimilar metals, our team carefully selects filler rods and processes to minimize the risk of cracking or joint failure.

Post-Weld Processes

Achieving a high-quality weld is only part of the assembly process. Post-weld treatments ensure that the final product meets aesthetic, functional, and structural requirements.

Surface Finishing

- Grinding and Polishing: For visible assemblies, welds are often ground and polished to create a smooth, seamless appearance. This is especially important for stainless steel parts used in medical or aerospace applications.

- Brushing or Bead Blasting: These processes remove surface imperfections and create a uniform finish, particularly for stainless steel.

Stress Relief and Warping Prevention

- Heat Treatment: Post-weld heat treatment (PWHT) is used to reduce residual stresses and improve weld strength, especially for materials like stainless steel.

- Clamping and Fixturing: Ensuring that the assembly remains aligned during and after welding helps to minimize distortion.

Cleaning and Corrosion Prevention

- Chemical Cleaning: Processes like passivation remove contaminants and restore the natural corrosion resistance of stainless steel.

- Painting or Powder Coating: A protective coating enhances the parts durability and appearance once the welds are complete.

Request a quote for custom sheet metal fabrication services that will exceed your expectations!

Sheet Metal Fabrication Weld Joints FAQ

The primary distinction lies in the gap between the metal edges. Open corner joints feature a visible gap, often used for thicker aluminum parts, while closed corner joints have flush edges with no gap. Both types require careful handling to prevent heat deformation and warping during welding.

Spot-welded flanges are effective for joining two metal pieces but require specific tooling and fixturing. Consequently, they're more cost-effective for larger production volumes. For smaller runs, the investment in tooling might not be as practical.

Our team evaluates various factors such as seam length, material type, and thickness. If you've specified a particular weld joint type and method, we'll aim to accommodate your preference. However, based on our expertise, we might suggest an alternative approach for better results, especially concerning heat-sensitive materials or specific joint requirements.

ASM offers various alternatives to welding, including rivets, tab and slot connectors, and Cleco fasteners. These methods cater to different assembly needs, providing options that avoid concerns like heat deformation and offering effective solutions for various applications.

Our experienced team is equipped with decades of expertise in custom sheet metal fabrication. Whether it's weld joints, rivets, tab and slot connectors, or Cleco fasteners, we ensure precise execution and a meticulous finish for every assembly, meeting and exceeding expectations.

Rivets

Rivets