Last updated on January 21st, 2026 at 09:48 am

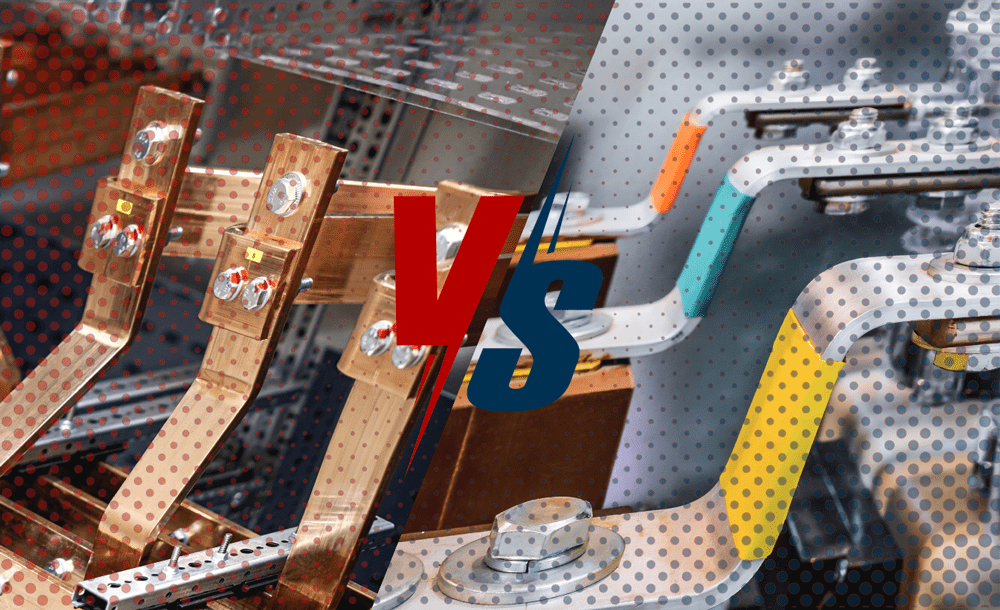

While busbars have become the go-to option for electricity distribution across a range of industries, it can be difficult to know which busbar material is right for your application. Should you opt for copper, which boasts higher conductivity, ampacity, and strength? Or would aluminum busbars be a better fit, thanks to their lower weight and cost?

Table of Contents

- 1 Choosing the Right Busbar Material for Your Application

- 2 When Aluminum Busbars Are the Better Choice

- 3 When Copper Busbars Are the Better Choice

- 4 8 Key Differences Between Copper and Aluminum Busbars

- 5 Practical Guidance for Selecting Busbar Materials

- 5.1 When to use copper busbars

- 5.2 When to use aluminum busbars

- 5.3 Additional Considerations for Selecting Busbar Materials

- 5.3.1 1. Environmental Impact

- 5.3.2 2. Thermal Conductivity

- 5.3.3 3. Load Handling and Stress

- 5.3.4 4. Surface Treatments and Coatings

- 5.3.5 5. Joining Methods

- 5.3.6 6. Voltage Drop and Energy Loss

- 5.3.7 7. Lifecycle Cost

- 5.3.8 8. Compatibility with Other Materials

- 5.3.9 9. Specific Applications by Industry

- 5.3.10 10. Regulatory Compliance

- 6 ASM Can Fabricate Copper and Aluminum Busbars to Your Specifications

- 7 Copper vs. Aluminum Busbars FAQ

- 7.0.1 What are the main differences in electrical conductivity between copper and aluminum busbars?

- 7.0.2 How does the strength of copper busbars compare to aluminum busbars?

- 7.0.3 Why might aluminum busbars be preferred in certain applications?

- 7.0.4 In what situations are copper busbars more advantageous?

- 7.0.5 What factors should be considered when choosing between copper and aluminum busbars for a project?

Choosing the Right Busbar Material for Your Application

When comparing copper and aluminum busbars, you should weigh electrical performance against weight and cost. Copper will generally carry more current in a smaller space and offer better long term conductivity. Aluminum will save cost and reduce weight but may require larger cross sectional area to meet the same current rating. Your specific application and design requirements will determine which material makes the most sense.

| Property | Copper | Aluminum |

|---|---|---|

| Electrical Conductivity | Very high, industry standard | Good, lower than copper |

| Weight | Heavy | Much lighter than copper |

| Cost | Higher per pound | Lower per pound and widely available |

| Corrosion Resistance | Good with plating | Good, may need surface finish |

| Fabrication Ease | Easy to machine, but heavy to handle | Easy to form and machine, lighter to handle |

| Thermal Performance | Excellent | Good but less than copper |

When Aluminum Busbars Are the Better Choice

Aluminum busbars are often selected when weight is a concern and conductivity requirements can be met with a larger cross section. In applications where lower cost and easier handling are priorities, aluminum is a strong fit. For example, aluminum is commonly used in solar energy equipment, electric vehicle structures, and large distribution boards where aluminum’s lighter weight reduces overall assembly weight. Fabricators can form and machine aluminum with less effort than copper, which can shorten lead times for higher volume work.

When Copper Busbars Are the Better Choice

Copper busbars excel when electrical performance cannot be compromised. Because copper has higher conductivity than aluminum, it requires a smaller cross section for the same current capacity. This makes copper ideal for high current power distribution, switchgear, and industrial busbar systems where space is limited and performance is critical. Copper is also the default choice where industry standards specify copper for safety or certification reasons. Plated copper offers excellent corrosion resistance and long service life in challenging environments.

8 Key Differences Between Copper and Aluminum Busbars

Before deciding on which material is right for your project, it’s important to understand the eight key differentiators between copper and aluminum fabrication for busbars.

1. Conductivity

Copper has higher electrical conductivity than aluminum, with roughly 58 MS/m (mega siemens per meter) versus the 37 MS/m found in aluminum. Copper busbars carry more current with less resistance, which can result in more efficient electrical systems.

Winner: Copper ✅

2. Ampacity

Thanks to their higher conductivity, copper busbars tend to have higher ampacity than aluminum busbars of the same dimensions. In practice, copper busbars’ conductivity allows them to carry more current without overheating.

Winner: Copper ✅

3. Strength

Copper is denser and has a higher tensile strength than aluminum making copper busbars more resistant to mechanical stress and deformation. Therefore, copper busbars can create more durable and reliable electrical connections. Still, if properly designed and fabricated, aluminum busbars can also be adequately strong for many applications.

Winner: Copper ✅

4. Corrosion resistance

In most environments, copper is more resistant to corrosion than aluminum. That said, aluminum can form a protective oxide layer, which can help prevent further corrosion in aluminum busbars for many applications.

Winner: Copper ✅

5. Thermal expansion

Aluminum has a higher thermal expansion coefficient than copper. For this reason, aluminum busbars might expand and contract more with temperature changes, which can lead to unstable connections and even mechanical failures. Copper busbars, on the other hand, generally have longer lifespans and lower maintenance costs thanks to their superior corrosion resistance and mechanical strength.

Winner: Copper ✅

6. Weight

Because aluminum is less dense than copper, aluminum fabrication delivers busbars that are lighter than copper ones of the same dimensions. Because copper busbars are heavier, they can be more difficult to transport, handle, and install.

Winner: Aluminum ✅

7. Cost

Aluminum is generally more affordable than copper, making aluminum busbars a better choice for large-scale applications where cost may be an issue.

Winner: Aluminum ✅

8. Availability

In some regions, copper may not be as widely available as aluminum, which can lead to longer lead times and higher procurement costs.

Winner: Aluminum ✅

Practical Guidance for Selecting Busbar Materials

When to use copper busbars

- High-performance electrical systems: If your project demands high conductivity and low resistance, such as in high-performance electrical systems (e.g., applications in power generation, transmission, distribution, and high-power electronics), you’ll likely want to opt for copper busbars.

- Critical infrastructure: Copper busbars are great for critical infrastructure projects where reliability and longevity are paramount, including substations, data centers, telecommunications facilities, and industrial plants.

- Harsh environments: If your application is in an outdoor or corrosive environment where busbars may be exposed to moisture, chemicals, or extreme temperatures, copper may be your preferred material, thanks to its heightened corrosion resistance and durability.

- Low-resistance connections: Copper busbars may be right for you if your project demands low-resistance connections, as is the case with high-current applications, motor control centers, switchgear, and power distribution panels.

When to use aluminum busbars

- Cost-sensitive applications: Aluminum busbars tend to be the better choice for projects where cost is a central concern.

- Lightweight applications: In sectors where weight is a core issue—such as the aerospace, automotive, marine, and portable electronics industries—lighter aluminum busbars tend to be the better option.

- Applications requiring heat dissipation: Aluminum busbars dissipate heat and prevent overheating better than their copper counterparts.

- Flexible applications: Aluminum's malleability allows for easier fabrication and bending compared to copper, marking aluminum busbars as the better choice for applications where flexibility is paramount, such as in busway systems and bus ducts.

- Utility-scale power systems: For utility-scale power systems, such as solar and wind farms, aluminum busbars tend to be the industry standard due to their low cost and suitability for high-voltage transmission and distribution.

Additional Considerations for Selecting Busbar Materials

1. Environmental Impact

The environmental footprint of your project may depend on the materials you select. Copper mining tends to have a higher environmental impact than aluminum extraction. However, both materials are highly recyclable. Aluminum recycling consumes significantly less energy compared to its primary production, making it a more eco-friendly option for sustainability-focused projects.

2. Thermal Conductivity

Thermal conductivity is another critical factor. Copper has higher thermal conductivity than aluminum, allowing it to transfer heat more efficiently. This characteristic is advantageous in high-performance electrical systems, where managing heat dissipation is crucial. On the other hand, aluminum busbars' lighter weight can provide better heat dissipation in large-scale systems, reducing risks of overheating.

3. Load Handling and Stress

Copper's superior tensile strength makes it better suited for applications subjected to high mechanical loads or frequent thermal cycling. Aluminum, while lighter, can be prone to deformation if not adequately designed. For projects involving heavy or dynamic mechanical stresses, copper may be the more reliable choice.

4. Surface Treatments and Coatings

Surface treatments can enhance the durability of both materials. Aluminum busbars often require anodizing or coating to improve corrosion resistance, especially in outdoor or marine environments. Copper busbars, while naturally more corrosion-resistant, can benefit from tin or silver plating for additional protection and conductivity in specific applications.

5. Joining Methods

The joining techniques for copper and aluminum differ due to their unique material properties. Aluminum forms an oxide layer that can complicate welding and requires specialized techniques such as ultrasonic or friction welding. Copper, being more malleable, offers easier soldering and brazing, which simplifies installation and maintenance.

6. Voltage Drop and Energy Loss

Copper's lower resistance results in less voltage drop and energy loss compared to aluminum. For high-efficiency systems or applications with long busbar lengths, this can translate into significant energy savings over the system's lifecycle.

7. Lifecycle Cost

While aluminum has a lower upfront cost, copper often proves more economical over the long term due to its durability, lower maintenance needs, and superior energy efficiency. For projects with a long expected lifespan, a lifecycle cost analysis may reveal copper as the more cost-effective choice.

8. Compatibility with Other Materials

Copper and aluminum busbars require different hardware and connectors. Aluminum, for example, often requires specialized clamps and coatings to mitigate galvanic corrosion when joined with other metals. Ensuring compatibility between the busbars and their connectors is crucial to avoid premature failures.

9. Specific Applications by Industry

Different industries have distinct requirements for busbar materials:

- Aerospace and Automotive: Aluminum is favored for its lightweight properties.

- Data Centers and Telecommunications: Copper is often the material of choice for its high conductivity and reliability in critical infrastructure.

- Renewable Energy Systems: Aluminum busbars dominate utility-scale solar and wind projects due to their cost-effectiveness and suitability for high-voltage applications.

10. Regulatory Compliance

Depending on your project’s location and industry, you may need to adhere to standards such as IEC, UL, or ANSI. These regulations can dictate material choices and design parameters. For instance, some standards may favor copper for safety-critical applications due to its superior performance under stress.

ASM Can Fabricate Copper and Aluminum Busbars to Your Specifications

As experts in custom sheet metal fabrication, we know that choosing your busbar material is just the beginning. When it comes to copper and aluminum fabrication for busbars, ASM employs turret punches, laser cutters, and press brakes to ensure precision and customization. These machines allow us to fabricate precision sheet metal busbars to the most detailed of specifications—all while minimizing costs and lead times.

Ready to get started on your next busbar project? Request a quote today!