Last updated on February 14th, 2025 at 10:18 am

Do you know how to select the right hardware for your precision sheet metal fabrication?

Many types of hardware accomplish the same end goal—for example, all fasteners connect parts—but there is a massive variety of hardware to choose from.

Generally, hardware can vary by type, material, thread code, thickness, shank, and length. Making the ideal selection for your part can be overwhelming, but don’t worry: Approved Sheet Metal is here to make the decision process much easier.

Table of Contents

- 1 8 Types of Hardware Used by Metal Fabricators

- 2 Sheet Metal Hardware Hole Sizes Chart

- 3 Common Mistakes in Hardware Selection

- 4 Cost vs. Performance Trade-offs in Hardware Selection

- 5 Choosing the Right Hardware for Your Precision Sheet Metal Fabrication

- 6 Precision Sheet Metal Hardware FAQ

- 6.0.1 What are the common types of hardware used in precision sheet metal fabrication?

- 6.0.2 How do PEM nuts differ from other fasteners in the industry?

- 6.0.3 What is the purpose of TY-D tie-down hardware in precision sheet metal fabrication?

- 6.0.4 How do locking nuts and fasteners benefit precision sheet metal fabrication?

- 6.0.5 What should I consider when selecting the right hardware for my precision sheet metal fabrication project?

8 Types of Hardware Used by Metal Fabricators

Let’s look at eight common hardware options for precision sheet metal fabrications:

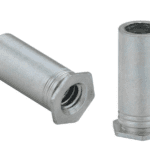

- PEM nuts. While known in the industry as PEM nuts, these parts are simply fasteners manufactured by PennEngineering. If PennEngineering doesn’t make the part, it’s called a self-clinching fastener, a threaded insert, or a captive fastener. A PEM nut is threaded onto another component, such as a standoff.

- Standoffs. Standoff fasteners are frequently used for the spacing and precision placement of other components. These fasteners are threaded into a nut.

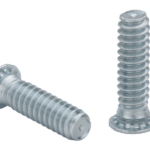

- Studs. A stud is a threaded bar of varying length and circumference. Studs are meant to be permanently attached to another part, often a nut, and can be welded, swaged, or bonded. Studs often resemble a screw without the flared head, though some studs do have a head on one end.

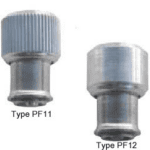

- Panel fasteners. Sometimes called captive panel screws, panel fasteners are similar to standard screws and have smooth or knurled caps. Most of these parts are designed for smaller applications and have a low profile.

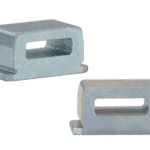

- TY-D tie-down. A TY-D tie-down is critical for cable management. The hardware has a square body with an eye to provide a secure way to guide cables and wire through an application. It’s self-clinching and doesn’t rely on screws or adhesives to hold it in place.

- Pins. Self-clinching pins are similar to studs, but they don't have threads. They can be produced in tiny sizes, and micro-pins are essential parts for today’s electronics, such as smartphones and smartwatches.

- Floating nuts and screws. Also known as floating self-clinching fasteners, floating nuts and screws have locking and non-locking threads. These parts can provide load-bearing strength in thin sheets.

- Locking nuts. Locking nuts and fasteners resist loosening and being “unlocked” when they experience vibration or movement. They have an internally threaded fastener with locking capabilities.

Common Mistakes in Hardware Selection

Selecting the wrong hardware for your precision sheet metal fabrication can lead to production delays, performance failures, and costly rework. Here are some of the most common mistakes to avoid:

1. Incorrect Thread Size or Type

Choosing the wrong thread size or pitch can lead to misalignment, stripping, or poor fastening strength. Always double-check the thread specifications against your part design.

2. Incompatible Material Choices

Mixing incompatible materials, such as using steel fasteners with aluminum parts, can cause galvanic corrosion over time. Always consider the long-term effects of material interactions in your application.

3. Improper Hole Sizing

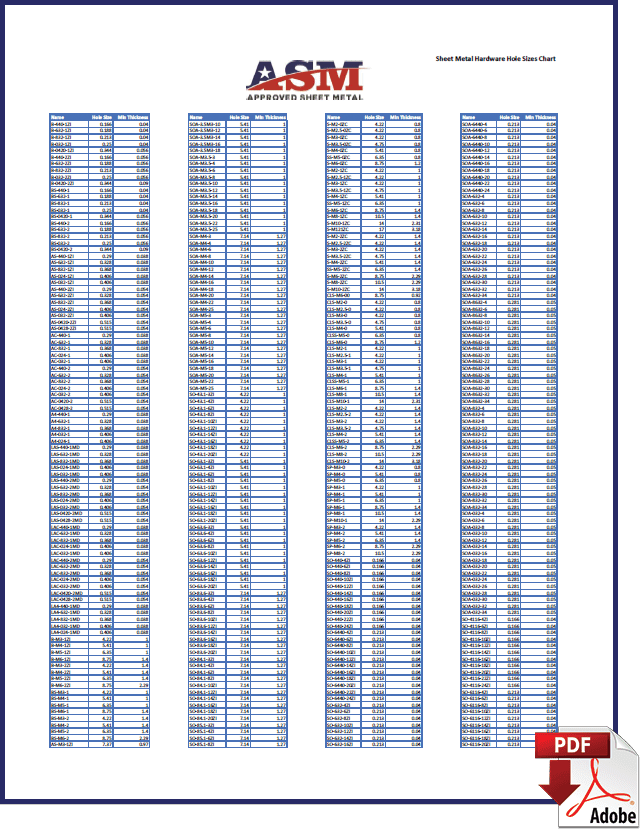

One of the most frequent design errors is using an incorrect hole size for self-clinching fasteners. If the hole is too large, the fastener won’t grip properly, leading to installation failures. Refer to manufacturer specifications or use a hardware hole size chart to ensure precision.

4. Overlooking Load Requirements

If the hardware cannot withstand the required load, your assembly may fail under stress. Consider shear strength, pull-out resistance, and vibration exposure when selecting fasteners.

5. Ignoring Environmental Conditions

Factors like moisture, chemicals, and extreme temperatures can weaken certain materials over time. Stainless steel or coated hardware may be necessary for applications exposed to harsh conditions.

6. Choosing Low-Quality or Unverified Hardware

Opting for off-brand or low-cost hardware without proper certifications can result in inconsistent performance. Stick with trusted manufacturers that meet industry standards.

By avoiding these mistakes, you can ensure a more reliable and efficient sheet metal fabrication process.

Cost vs. Performance Trade-offs in Hardware Selection

While it’s tempting to choose the cheapest hardware option, doing so can lead to long-term issues such as premature wear, failure under stress, or additional labor costs. Here’s how to balance cost and performance in hardware selection:

1. Upfront Cost vs. Lifetime Cost

Lower-cost hardware might save money initially but can lead to increased maintenance, replacement, or failure costs over time. Investing in high-quality fasteners reduces long-term expenses and improves reliability.

2. Labor and Assembly Considerations

Some hardware options, like self-clinching fasteners, may have a slightly higher upfront cost but significantly reduce installation time compared to welding or adhesive-based alternatives. Consider how labor costs factor into your decision.

3. Material Selection and Durability

Standard steel hardware is often the cheapest option, but it may not provide adequate corrosion resistance. Stainless steel or aluminum fasteners may cost more but are necessary for certain environments.

4. Precision and Performance

Higher-quality fasteners are manufactured with tighter tolerances, reducing the risk of misalignment, stripped threads, or installation failures. If precision is critical, investing in premium hardware is worthwhile.

5. Industry Compliance and Safety

Some applications require hardware that meets specific industry standards (e.g., MIL-SPEC, RoHS, REACH). While compliant hardware may be more expensive, failing to meet regulatory requirements can result in fines, recalls, or operational shutdowns.

By carefully weighing cost vs. performance trade-offs, you can make informed decisions that optimize both budget and product reliability.

Choosing the Right Hardware for Your Precision Sheet Metal Fabrication

To choose the right type of hardware for your project, start by considering the application itself. Your design will dictate requirements such as length, load-bearing capacity, and locking capabilities.

Once you know what type of hardware you need, the next step is to identify the ideal hardware material for your application—which can be more complicated than you might think.

Many engineers opt for steel hardware when designing sheet metal parts because it’s the cheapest and easiest option, but it’s not always optimal. In fact, if you’re working with aluminum or stainless steel in your fabrication process, steel hardware is an inadequate option.

For one thing, steel doesn’t stand up to plating. And because steel is softer than stainless steel, knurls won’t grip the material properly, potentially causing the hardware to fall out under pressure.

Choosing the wrong type of hardware material can be a costly mistake, so we recommend working with a sheet metal fabrication shop to confirm your plans.

If you’re looking for a partner in precision fabrication and would like a shop that respects your knowledge and expertise while offering guidance on hardware selection—let’s talk!

We can help you with all things hardware, from material type to hole sizes. Give us a shot on your next project: request a quote today.

Precision Sheet Metal Hardware FAQ

The common types of hardware used in precision sheet metal fabrication include PEM Nuts, Standoffs, Studs, Panel Fasteners, TY-D tie-downs, Pins, Floating nuts & screws, and Locking nuts.

PEM nuts are simply fasteners manufactured by PennEngineering. If PennEngineering doesn't make the part, it's referred to as a self-clinching fastener, a threaded insert, or a captive fastener. PEM nuts are threaded onto another component, such as a standoff.

TY-D tie-down hardware is critical for cable management. It has a square body with an eye to securely guide cables and wires through an application. Unlike screws or adhesives, TY-D tie-downs are self-clinching and don't rely on additional fastening methods.

Locking nuts and fasteners resist loosening and unlocking due to vibration or movement. They provide additional security and stability in applications where movement or vibration is a concern.

When selecting the right hardware, consider the specific application requirements such as length, load-bearing capacity, and locking capabilities. Additionally, choose the appropriate hardware material based on the sheet metal material used. Steel hardware may not be suitable for aluminum or stainless steel fabrication due to potential issues with plating and grip. Consulting with a sheet metal fabrication shop can help ensure you make the correct hardware selection for your project.