Last updated on January 2nd, 2025 at 01:02 pm

Have you ever wondered what type of welding is best for your precision sheet metal prototype or production run?

We excel at high-quality welding at Approved Sheet Metal using three different techniques: spot welding, seam welding, and plug welding.

Spot and seam welding are both standard assembly methods, but it’s important to consider which is right for your part.

Table of Contents

- 1 Spot Weld vs. Seam Weld

- 2 7 Things to Know About Spot Welding

- 3 Sheet Metal Part Design for Manufacturing Tip

- 4 Spot Welding FAQ

- 4.0.1 What is the difference between spot welding and seam welding, and when should I choose one over the other?

- 4.0.2 What is plug welding, and when should I consider it for my sheet metal fabrication project?

- 4.0.3 Is spot welding suitable for high-strength applications in sheet metal fabrication?

- 4.0.4 Why should I choose spot welding over seam welding for my sheet metal project?

- 4.0.5 What are the different welding techniques offered by Approved Sheet Metal for precision sheet metal prototypes and production runs?

Spot Weld vs. Seam Weld

Need a refresher on spot and seam welding? You got it!

Spot welding consists of firing an electrical current through two pins that are pinching two or more layers of sheet metal together. As the wire heats up, the material melts into a coin at the point of contact, fusing the material.

Seam welding uses electrical resistance to create a smooth, continuous joint between the metal sheets.

7 Things to Know About Spot Welding

Our team recommends a spot weld over a seam weld whenever possible. Here are seven factors to consider:

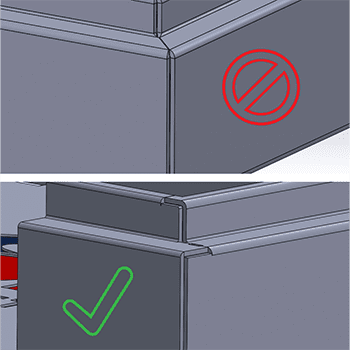

1. Class A finish

With a spot welded part, we can adjust the design so that the material overlaps itself, eliminating the need for grinding after welding. Essentially, we can deliver a Class A finish right off the bat, which saves our customers time and money while making their parts look spectacular.

2. Specific thickness range

Spot weldments are best when welding material 0.020”-0.090” thick. Materials thicker than 0.090” aren’t suitable for a spot weld because the weldment won’t be strong enough, and welding can burn through materials thinner than 0.020”.

For thicker parts, plug welding is a better option. Also known as rosette welding, plug welding is a specialized type of spot welding performed by TIG welders. Like spot welding, plug welding fuses material by making coin-like deposits on overlapping sheet metal.

However, with plug welding, the welder cuts holes into one sheet instead of using metal pins. Heat melts the metal, filling the hole and fusing the two parts. The result is a smooth finish that doesn’t require additional grinding.

3. High strength (within range)

There’s a common misconception that seam weldments are stronger than spot weldments, but it’s simply not true!

Strength isn’t an issue as long as we perform spot weldments on materials within the appropriate thickness range. Below or above that range, a spot weld could compromise the strength of the sheet metal fabrication.

4. Not watertight

A spot weld is not suitable for watertight applications. In contrast, full-seam welding can produce airtight welds and watertight seals.

We recommend seam welding for customers working on marine applications, tanks, shipping containers, pressure vessels, and nuclear components.

5. Ideal for hat channels

Spot welding is ideal for creating hat channels. Hat channels—which look like a top hat— stiffen up a flat piece of metal and are especially useful when reducing the flexibility of a larger piece of material

6. Time- and cost-efficient for higher-volume projects

A simple, automated process requiring minimal setup, spot welding is the fastest and most cost-effective option for high-volume production.

Customers ordering sheet metal prototypes may not notice as much of a difference in price, but those ordering higher volumes of parts can save up to 50% on the cost of spot compared to seam welding.

7. Placement matters

A spot weld requires strategic placement to ensure the part functions properly.

Customers are welcome to indicate specific locations for spot welding in their print. However, to make the RFQ process even easier, we recommend you specify “spot welding” and leave the placement to us. With 20+ years of experience welding precision sheet metal parts, we know exactly where to place these weldments.

Industry Standards and Specifications

Adhering to recognized standards ensures consistency, safety, and compatibility in sheet metal fabrication. Key standards include:

- Material Standards: Specifications such as ASTM (American Society for Testing and Materials) standards define material properties, ensuring appropriate selection for specific applications.

- Welding Standards: Guidelines from organizations like the American Welding Society (AWS) provide criteria for welding processes, ensuring structural integrity and safety.

- Finish Standards: Standards like those from the Society of Automotive Engineers (SAE) outline surface finish requirements, ensuring aesthetic and functional quality.

Design Considerations and Limitations

When designing sheet metal parts, consider the following:

- Material Thickness: Spot welding is effective for materials between 0.020” and 0.090” thick. Materials outside this range may require alternative welding methods.

- Weld Accessibility: Ensure design allows easy access for welding electrodes, especially in complex geometries. Proper flange design can facilitate this.

- Thermal Effects: Be aware of potential material distortion due to heat during welding, which can affect dimensional accuracy.

- Aesthetic Requirements: For visible parts, choose appropriate finishing processes to achieve the desired surface quality.

- Functional Requirements: Consider the part's end-use, such as load-bearing needs or exposure to environmental factors, to inform material and process selection.

By integrating these standards and design considerations, you can enhance the performance, durability, and quality of your custom sheet metal parts.

For a visual understanding of spot and seam welding processes, you might find the following video helpful:

Although welding is one of the oldest forms of manufacturing in the world, it can be confusing and complicated. Approved Sheet Metal is here to help you choose the best welding technique for your part, so please don’t hesitate to ask us any questions you might have.

Let’s work together on your next welding project. Request a quote to get started.

Spot Welding FAQ

Spot welding involves fusing two or more layers of sheet metal by passing an electrical current through metal pins, creating a coin-like deposit at the point of contact. Seam welding, on the other hand, creates a smooth, continuous joint between metal sheets using electrical resistance. It is recommended to choose spot welding for a Class A finish, specific thickness ranges, high strength within the range, and time- and cost-efficiency. Seam welding is preferable for watertight applications and specific projects like marine applications, tanks, and pressure vessels.

Plug welding, also known as rosette welding, is a specialized form of spot welding. It is performed by TIG welders and involves cutting holes into one sheet of metal and then fusing the two parts by melting the metal. Plug welding is ideal for thicker materials and offers a smooth finish without the need for additional grinding. It is a suitable option when spot welding isn't feasible due to material thickness.

Spot welding is suitable for high-strength applications within the recommended thickness range (0.20”-0.90”). Contrary to common misconceptions, spot weldments can provide the necessary strength for sheet metal fabrication within this range. However, for applications outside this range, alternative welding methods like plug welding may be more appropriate.

Spot welding offers several advantages, including a Class A finish without the need for grinding, cost and time efficiency for high-volume projects, and suitability for creating hat channels. It is also a versatile option within the specific thickness range. If you're unsure about the placement of spot welds, Approved Sheet Metal's experienced team can handle the placement strategically to ensure the part functions correctly, making it a convenient choice for many sheet metal projects.

Approved Sheet Metal offers three different welding techniques: spot welding, seam welding, and plug welding. These techniques cater to various needs and specifications for welding precision sheet metal parts.