Last updated on March 11th, 2025 at 09:24 am

At Approved Sheet Metal, we bring decades of expertise to custom sheet metal fabrication. A crucial aspect of our craft is sheet metal forming, which shapes metal sheets into desired forms without removing any material. Most fabricated sheet metal parts require some degree of forming.

One of the most common and essential types of sheet metal forming is bending. When you bend a piece of sheet metal, the metal in and around the bend stretches, resulting in a longer final piece than the original flat piece. Understanding the impact of bending on the material is vital when designing parts.

To help you achieve the highest standard of fit and function for your parts, we're sharing the top 5 sheet metal design formulas you need to consider for bending. These design formulas were created to optimize your designs and ensure precision. If you have any questions about the design formulas or their application in your design process, don't hesitate to reach out to us. Our metal fabrication experts are here to assist you.

Table of Contents

- 1 5 Important Sheet Metal Design Formulas

- 2 Practical Applications in Custom Sheet Metal Fabrication

- 3 Sheet Metal Design Formula FAQ

- 3.0.1 What is the K-Factor and why is it important in sheet metal design?

- 3.0.2 How do I calculate the Bend Allowance for a sheet metal part?

- 3.0.3 What is the difference between Bend Deduction and Bend Allowance?

- 3.0.4 Why is the Inside Setback important in sheet metal design?

- 3.0.5 How does the Outside Setback differ from the Inside Setback?

5 Important Sheet Metal Design Formulas

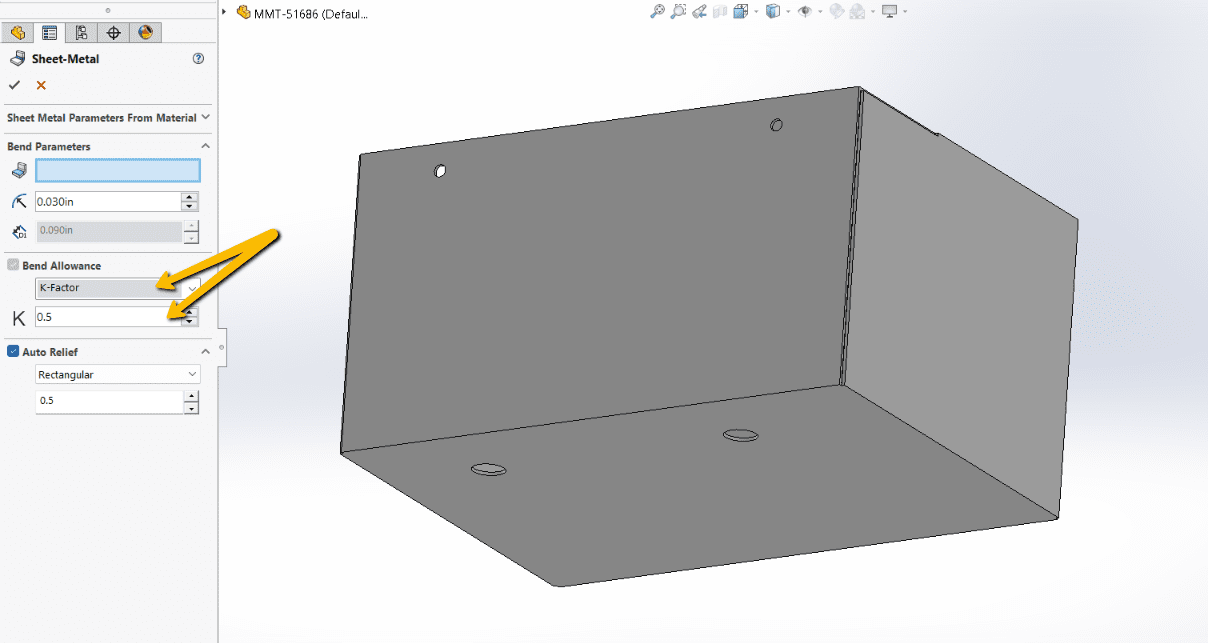

#1 K-Factor

The K-Factor is a crucial parameter used to determine how much a given material will stretch or compress during bending. The K-Factor is used to calculate the Bend Deduction and Bend Allowance (formulas #2 and #3), which in turn are used to determine the correct size of the unfolded flat pattern for the part.

Understanding the K-Factor

The K-Factor represents the ratio of the location of the neutral axis to the material thickness. The neutral axis is the theoretical line within the material that experiences no compression or tension during bending.

where:

- BA is the bend allowance

- B< is the bend angle

- IR is the inside radius

- MT is the material thickness

The K-Factor is a dimensionless value and typically ranges between 0 and 0.5 for most sheet metal materials and bending operations. The value depends on several factors, including material type, thickness, and bend radius.

K = 0: The neutral axis is located at the outer surface of the bend, which is unrealistic for practical purposes.

K = 0.5: The neutral axis is located exactly halfway through the thickness of the material, which typically occurs with very soft materials or very large bend radii.

Practical Range: For most practical applications, the K-Factor ranges between 0.3 and 0.5.

At Approved Sheet Metal, we use the K-Factor most often to compute bend deductions for non-90 degree bends, like offsets and hems.

#2 Bend Allowance

The Bend Allowance (BA) is the length of the neutral axis in a bend. If you add the bend allowance to the leg lengths of the part, you will get the required length of the flat pattern.

Why Bend Allowance is Important

- Accurate Dimensions: Without accounting for the Bend Allowance, the final part dimensions would be incorrect. The Bend Allowance ensures that when the part is bent, it will match the specified dimensions in the design.

- Material Utilization: Properly calculating Bend Allowance helps in optimizing the use of material, reducing waste, and controlling costs. It ensures that the cut piece of sheet metal will be the correct size after bending.

- Fit and Assembly: Parts that are bent to incorrect dimensions may not fit together properly, leading to assembly issues. By incorporating the correct Bend Allowance, parts will fit together as intended.

- Stress and Structural Integrity: Incorrect bend calculations can result in too much or too little material in the bend area, potentially weakening the part or causing it to fail under stress.

How Bend Allowance is Calculated

Bend allowance depends on several factors, including the material thickness (T), the bend radius (R), the bend angle (A), and the K-factor (K), which accounts for the location of the neutral axis.

Computing the bend allowance is much like calculating the arc length on a circle. First, determine the radius of the neutral axis, starting with the inside bend radius and adding an adjustment using the K-Factor and the material thickness. Then, multiply by the bend angle in radians.

The formula for bend allowance (BA) is:

where:

- MT is the material thickness

- B < is the bend angle

- IR is the inside radius

- K is the K-factor, which typically ranges between 0.3 and 0.5 for most metals and bending operations

#3 Bend Deduction

Bend Deduction (BD) is the amount you must subtract from the desired part size to get the correct length of the flat pattern, in order to compensate for the amount the material will stretch during bending.

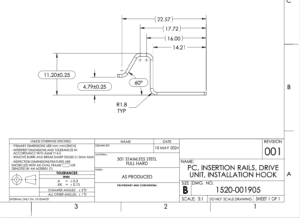

We use the Bend Deduction formula every day at Approved Sheet Metal to compute our standard sheet metal bend gains chart. This chart serves as a handy reference for bend deductions with a variety of materials and thicknesses, and is a valuable resource for understanding how sheet metal stretches when bent.

Why Bend Deduction is Important

- Accurate Flat Pattern Layout: Bend Deduction ensures that the flat pattern is dimensioned correctly so that, after bending, the part matches the desired final dimensions. This is crucial for precision and proper fit in assembly.

- Consistency in Fabrication: By using Bend Deduction, fabricators can consistently produce parts that meet design specifications, leading to fewer errors and rework.

- Material Efficiency: Properly calculated Bend Deduction helps in minimizing material waste, ensuring efficient use of resources.

- Ease of Manufacturing: Bend Deduction simplifies the calculation process for the flat pattern layout, making it easier for fabricators to cut and bend the sheet metal accurately.

How Bend Deduction is Calculated

Bend Deduction depends on the bend angle (A), the material thickness (T), the inside bend radius (R), and the K-factor (K). It is derived from the relationship between the Bend Allowance and the initial flat length. The formula for Bend Deduction (BD) is:

where:

- MT is the material thickness

- B < is the bend angle

- IR is the inside radius

- K is the K-factor, which typically ranges between 0.3 and 0.5 for most metals and bending operations

#4 Inside Setback

When designing two mating flanges, it is important to keep in mind the curvature of the bends. For example, a 90° bend is not truly square – it has a radius, and a mating flange cannot sit flush with both interior edges of the bend. As such, a mating flange must be “set back” by a specified amount to ensure a proper fit when the flanges are assembled. This amount is called the Inside Setback (SB).

Why Inside Setback is Important

- Accurate Flat Pattern Layout: Inside Setback ensures that the flat pattern is dimensioned correctly, allowing for precise bending and resulting in a part that matches the desired final dimensions.

- Proper Fit and Assembly: Accurately calculating Inside Setback ensures that bent parts fit together correctly during assembly, avoiding issues that could arise from inaccurate bends.

Understanding Inside Setback

Inside Setback is based on the material thickness (T) and the inside bend radius (R). It is used in conjunction with the bend angle (A) to determine the precise length of the flat pattern. The Inside Setback does not depend on the material, only on the geometry of the bend.

The formula for Inside Setback is:

where:

- MT is the material thickness

- B < is the bend angle

- IR is the inside radius

#5 Outside Setback

Like the Inside Setback, the Outside Setback (OSSB) is an important consideration when designing mating flanges. Since bends are not perfect squares, but are instead rounded, a mating flange cannot sit flush with both exterior edges of a bend without creating an undesirable overhang. Outside Setback determines how much a mating flange must be “set back” to avoid such overhang.

Why Outside Setback is Important

- Accurate Flat Pattern Layout: Outside Setback ensures that the flat pattern is dimensioned correctly, leading to precise bends and a part that meets the desired specifications.

- Proper Fit and Assembly: Accurate Outside Setback calculations ensure that bent parts fit together correctly during assembly, avoiding issues related to misalignment or improper fit.

Understanding Outside Setback

Outside Setback (OSSB) depends on the material thickness (T), the inside bend radius (R), and the bend angle (A). It is used to determine the distance from the outside edge of the bend to the mold line intersection. Like the Inside Setback, the Outside Setback does not depend on the material, only on the geometry of the bend.

The formula for Outside Setback is:

where:

- MT is the material thickness

- B < is the bend angle

- IR is the inside radius

Practical Applications in Custom Sheet Metal Fabrication

Using these design formulas will ensure that your sheet metal parts are fabricated to your exact specifications. At this point, you may be thinking, “These design formulas are very complicated!” If so, don’t worry! As a precision sheet metal fabricator, we work with K-Factors and Bend Deductions on a daily basis to produce parts of the highest quality for our customers.

At Approved Sheet Metal, we are dedicated to excellence in our work and to helping you achieve outstanding results. With our numerous manufacturing resources, our team is committed to ensuring you achieve exceptional outcomes with every order.

Request a quote to work with us today.

Sheet Metal Design Formula FAQ

The K-Factor is a crucial parameter that helps calculate how much material will stretch or compress during bending. It represents the ratio of the neutral axis location to the material thickness. The K-Factor is essential for determining Bend Deduction and Bend Allowance, ensuring accurate flat pattern dimensions and proper fit during fabrication.

The Bend Allowance (BA) is the length of the neutral axis in a bend, calculated using the material thickness, bend radius, bend angle, and the K-factor. The formula is:BA = (π/180) * Bend Angle * (Inside Radius + K * Material Thickness)

Proper calculation of the Bend Allowance ensures that the part will meet the specified dimensions after bending.

Bend Deduction (BD) refers to the amount you subtract from the desired part size to account for material stretching during bending. Bend Allowance (BA), on the other hand, measures the length of the neutral axis in the bend. Both formulas are crucial in determining the correct size of the flat pattern before bending to ensure accurate fit and function.

The Inside Setback (SB) accounts for the curvature of bends, especially when designing two mating flanges. It ensures that flanges do not sit flush with both interior edges of the bend, preventing assembly issues. The Inside Setback is calculated based on the material thickness and inside bend radius.

The Outside Setback (OSSB) is similar to the Inside Setback but applies to the exterior edges of a bend. It prevents overhang when two mating flanges are assembled, ensuring a proper fit. The Outside Setback is calculated using the material thickness, bend radius, and bend angle. It plays a critical role in accurate flat pattern layout and proper fitment of bent parts.