Last updated on March 19th, 2025 at 08:27 am

Before you click “Submit” on your quote request, make sure you’ve uploaded a print and a CAD model for your part!

Keep reading to find out why a 3D CAD model matters so much and what can happen when we’re missing that key document.

Table of Contents

- 1 Here’s Why Our Metal Fabrication Shop Requires 3D CAD Models

- 2 Compatibility & File Formats: Choosing the Right CAD File for Fabrication

- 3 CAD Models and Custom Sheet Metal Fabrication

- 4 Sheet Metal Part Design for Manufacturing Tip

- 5 3D CAD Models in Metal Fabrication FAQ

- 5.0.1 Why is a 3D CAD model essential when requesting a quote for custom sheet metal fabrication?

- 5.0.2 What limitations exist when submitting only a 2D print without a CAD model?

- 5.0.3 How does a CAD model improve the quoting experience and speed up the process?

- 5.0.4 Can the metal fabrication shop create a CAD model if one isn't provided?

- 5.0.5 What advantages does submitting a 3D CAD model offer in custom sheet metal fabrication?

Here’s Why Our Metal Fabrication Shop Requires 3D CAD Models

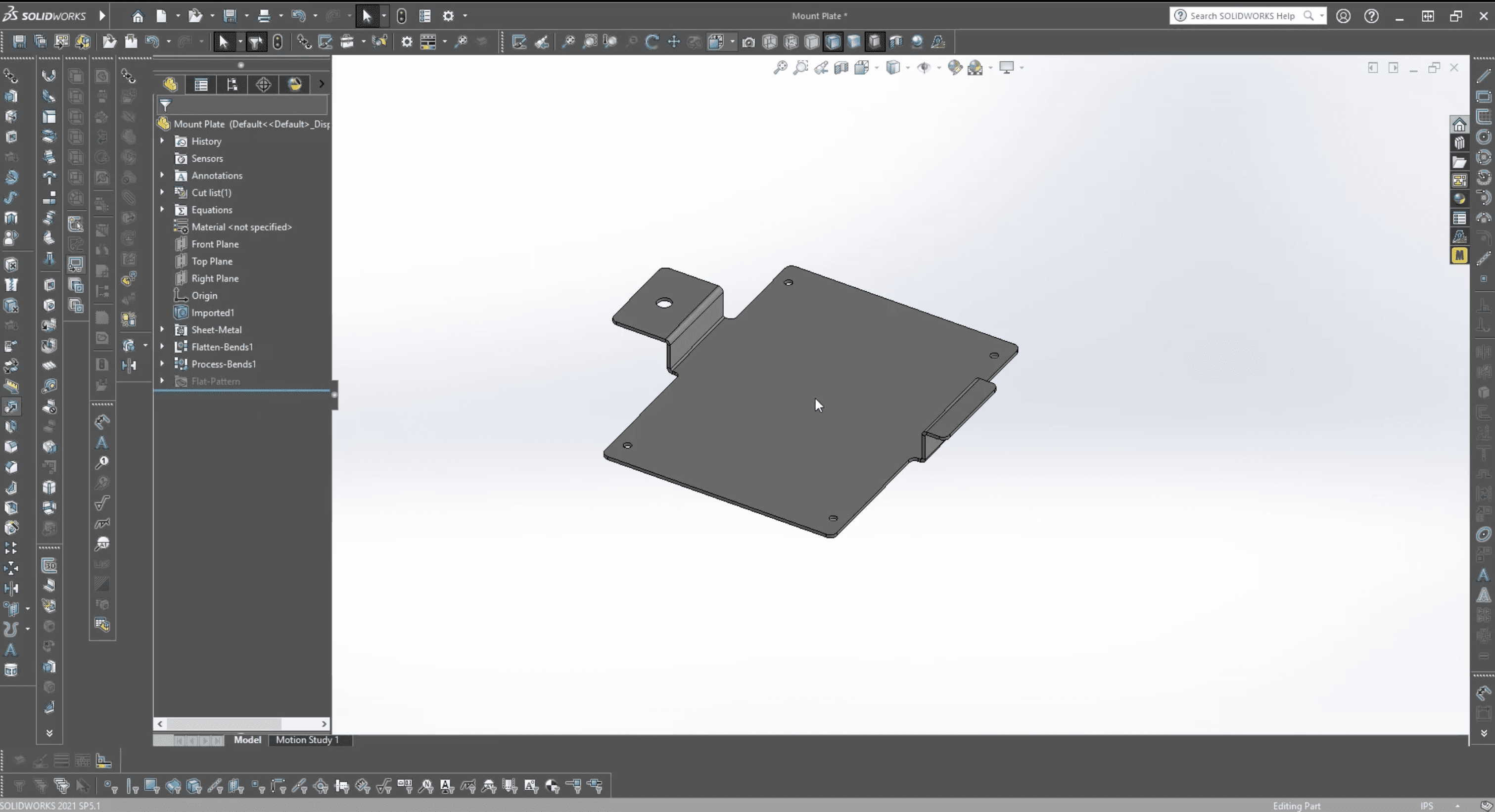

Our quoting department receives several RFQs every day that don’t include a CAD model. But like most of today’s top manufacturers, Approved Sheet Metal requires a 3D model before we can manufacture your parts—and sometimes even before we can accurately quote them.

Why a 2D print isn’t enough

Prints rarely reveal the full scope of your project, sometimes because of missing callouts, other times because of unseen features. When we can’t review every aspect of your design, we may overlook critical details that should be addressed before we begin your job.

Special tooling, for example, is a significant consideration. And if we don’t realize your part will need it, we’ll all be in for some unpleasant surprises as we dive into your custom sheet metal fabrication project.

How a CAD model improves your quoting experience

- Speed. When our metal fabrication shop has a 3D model, we can generate an accurate quote in only two to three minutes! Without the CAD model, however, we have to manually enter your part’s data from your print, which can easily add 15 to 20 minutes to our quoting time.

Or, if your print is lacking crucial information, we’ll be forced to reach out to you for the missing details, which delays the start of your project and robs you of time better spent focusing on your next project.

- Automation. While we prefer not to spend extensive time on data entry, our greater concern is the possibility of human error when manually entering a part’s specifications.

When we create a quote without a CAD model, our team must rely on manual calculations. With a CAD model, our metal fabrication shop can eliminate manual data entry from the quoting process altogether. Instead, our state-of-the-art quoting software will integrate your part design details automatically and 100% accurately.

- Quality. When we have your CAD model, we can unfold the design, transfer the pattern to our laser, refold the model, and then proceed with forming and bending.

- Value. A CAD model can help us quickly identify potential problems well before they cost you a single penny. From there, we can make Design for Manufacturing recommendations and help you refine your part design for optimized fabrication.

When we’ve watched your 3D model unfold and refold successfully, our metal fabrication shop can provide you with the lowest price and shortest lead time.

Compatibility & File Formats: Choosing the Right CAD File for Fabrication

Submitting the correct CAD file format ensures a smooth transition from design to fabrication, minimizing errors and optimizing production efficiency. Different file types serve different purposes, and understanding which format to provide can help avoid delays and misinterpretations.

Preferred File Types for Sheet Metal Fabrication

Most metal fabrication shops, including Approved Sheet Metal, work best with neutral CAD formats that preserve model accuracy and compatibility across different software systems:

✅ STEP (.step, .stp) – The most universally accepted format for 3D CAD models, preserving solid geometry and parametric data.

✅ IGES (.iges, .igs) – Another widely used format, but with potential limitations in complex curvature and surface data.

✅ DXF (.dxf) – Essential for 2D flat pattern exports, used in laser cutting, punching, and waterjet machining.

✅ DWG (.dwg) – Often used for 2D prints, though compatibility varies depending on software versions.

Proprietary Formats & Their Limitations

While software-specific formats like SolidWorks (.sldprt), Fusion 360 (.f3d), or Inventor (.ipt) retain full parametric history, they are not always compatible with all fabrication software. Some shops may require conversion to STEP or DXF to ensure seamless integration with CAM (Computer-Aided Manufacturing) tools.

Avoiding Common Export Errors

When exporting CAD models for fabrication, engineers should double-check the following to prevent costly production issues:

⚠️ Missing Bend Data – Ensure that all bends and reliefs are correctly translated in the exported file, especially in flat pattern exports.

⚠️ Feature Loss – Some CAD conversions may lose important hole callouts, fillets, or thread specifications. Always verify exports before submission.

⚠️ Incorrect Units or Scale – Verify that the CAD file is in the correct measurement system (inch vs. mm) to avoid scaling issues in fabrication.

⚠️ Overly Complex Geometry – Simplify unnecessary model details that don’t impact manufacturing, reducing processing time and potential software compatibility problems.

What happens if you don’t have a CAD file..

Can our metal fabrication shop create a CAD model for you? Absolutely! There is a cost for our CAD services, but we’re happy to use your fully dimensioned 2D prints to make a 3D CAD model.

CAD Models and Custom Sheet Metal Fabrication

The advantages of submitting a 3D CAD model with your RFQ can’t be overstated.

Include your 3D model, and you’ll get a fast, accurate quote with little to no chance of data entry errors. You’ll also avoid fielding questions about your part’s specifications—questions that could slow down production after you’ve placed your part order.

This one simple tip is the number one way our customers can get top-quality parts at the best price in the least amount of time. Include a 3D CAD model any time you submit an RFQ for custom sheet metal fabrication services:

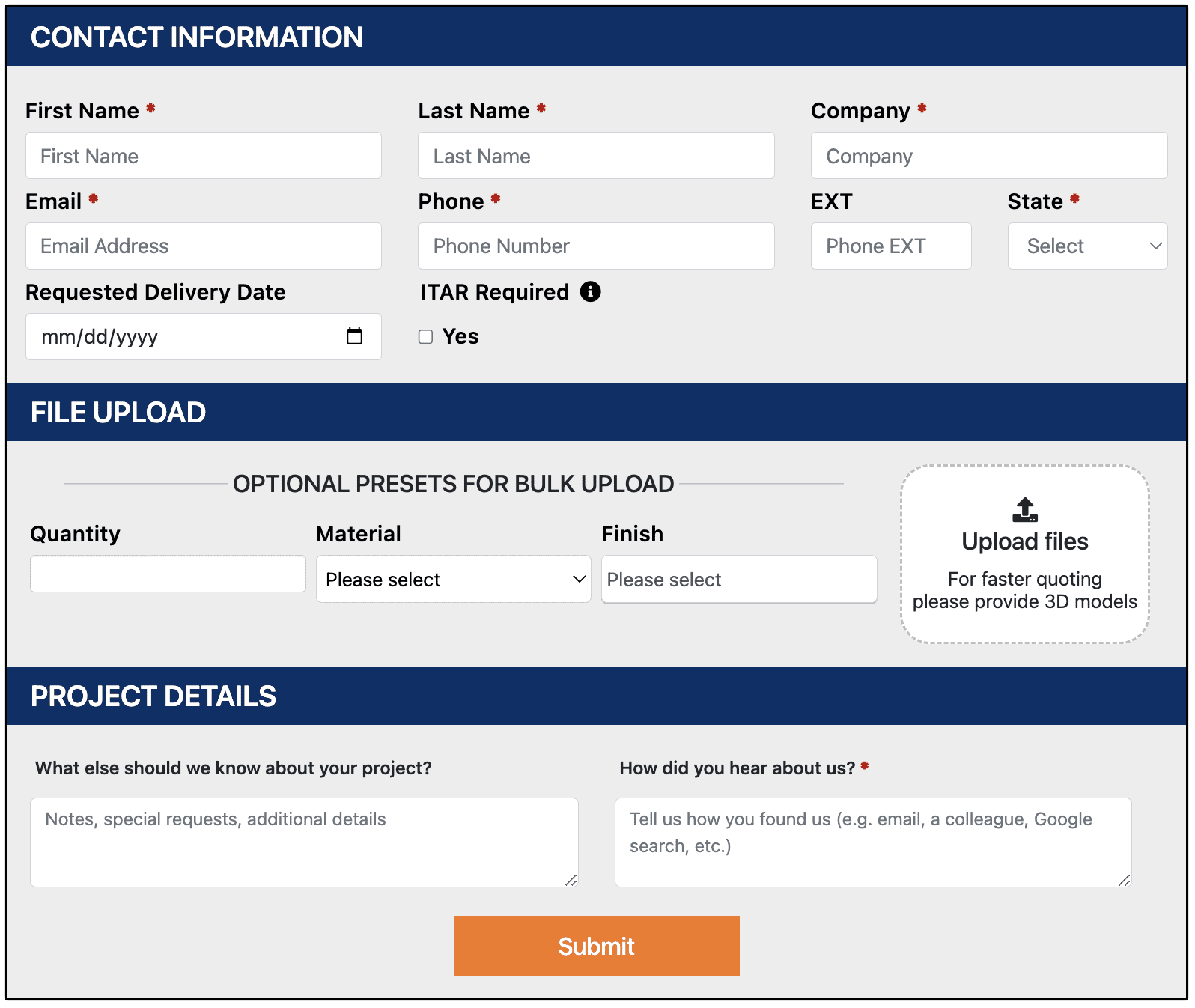

Request a quote from our secure quoting portal—and don’t forget to upload your CAD model!

3D CAD Models in Metal Fabrication FAQ

A 3D CAD model provides a comprehensive view of your part's design, aiding in identifying critical details and potential issues early in the process, ultimately ensuring accurate quoting and efficient fabrication.

2D prints may lack crucial details or unseen features, potentially leading to oversights in critical aspects like necessary tooling. This can result in delays, additional inquiries for missing information, and potentially unpleasant surprises during fabrication.

Having a 3D model drastically accelerates the quoting process, reducing the time required from 15 to 20 minutes for manual data entry from prints to just 2 to 3 minutes. Automation through CAD integration ensures 100% accuracy and eliminates human error.

Absolutely! The shop offers CAD services using fully dimensioned 2D prints for a fee. This service ensures the creation of a 3D CAD model to facilitate accurate quoting and manufacturing.

Submitting a 3D CAD model guarantees fast and precise quoting, minimizing the chances of errors in data entry. It also reduces queries about part specifications, streamlining production processes after placing an order, ultimately ensuring top-quality parts at the best price and shortest lead time.