Last updated on April 2nd, 2025 at 09:44 am

Welding is one of the oldest fabrication methods in human history. As far back as the Bronze Age, humans have been assembling smaller parts and fusing them together to create larger pieces. Even blacksmithing was an early form of welding.

Today, welding is a common manufacturing process that produces parts for cars, aircraft, houses, buildings, engines, high-pressure vessels, and more. The old spark-to-metal application may seem archaic, but as the saying goes, “A good welder can weld anything from the crack of dawn to a broken heart.”

At Approved Sheet Metal, we specialize in various weldment techniques and leverage best practices to meet the specifications of every project we take on.

Table of Contents

- 1 3 Expert Weldment Techniques at Approved Sheet Metal

- 2 Weldment Best Practices at Approved Sheet Metal

- 3 Welding Design & Engineering Best Practices

- 4 Sheet Metal Part Design for Manufacturing Tip

- 5 Sheet Metal Weldment Techniques FAQ

- 5.0.1 What is welding, and how does it relate to historical fabrication methods?

- 5.0.2 What are some expert weldment techniques used at Approved Sheet Metal?

- 5.0.3 What is spot welding, and where is it commonly used?

- 5.0.4 When is seam welding preferred, and what are its advantages?

- 5.0.5 What is plug welding, and why is it popular in the automotive industry?

3 Expert Weldment Techniques at Approved Sheet Metal

A weldment is a larger unit formed by welding an assembly of custom sheet metal pieces together.

When dealing with larger parts, basic MIG or TIG welding techniques aren’t always the most efficient or cost-effective solutions. Our team uses different welding methods to streamline the process of creating quick-turn assembled parts.

Spot Welding

Spot welding consists of firing an electrical current through two pins pinching two or more layers of sheet metal together. As the wire heats up, the material melts into a coin at the point of contact, fusing the materials.

The simple, automated process requires minimal setup, making spot welding the most efficient and cost-effective welding option for high-volume production. Common applications include electronics, solar panels, and automobile parts.

Seam Welding

When layering two workpieces together to form a longer piece, the surface becomes irregular at the seams. Seam welding uses electrical resistance to create a smooth, continuous joint between the metal sheets.

Resistance seam welding can produce airtight welds and watertight seals, making it ideal for marine applications, tanks, shipping containers, pressure vessels, and nuclear components.

Seam welding is faster than spot welding and doesn’t require filler material, though material thickness is limited to 3 mm per sheet.

Plug Welding

Also known as rosette welding, plug welding is widely used in the automotive industry.

Similar to spot welding, plug welding fuses material together by making coin-like deposits on overlapping sheet metal. Instead of using two pins to cinch the sheets, the welder cuts holes into one sheet and layers it over another. Once heat is applied, the metal melts, fills the hole, and fuses the two parts together.

For manufacturing hot rods or performing auto repairs, plug welding is a versatile and durable option.

Weldment Best Practices at Approved Sheet Metal

Led by our in-house master welder, Gerald Fanning, Approved Sheet Metal’s welding team follows strict best practices:

- Using low heat to avoid metal distortion. Too much heat can curve, oil-can, or warp a part. Our experienced team carefully controls welding temperatures to maintain strength without heat distortion.

- Cleco holes for precision alignment. Using CAD software, we add alignment holes into your design to ensure precision placement for all assembly parts.

- Custom fixtures. Parts tend to move when heat is applied, so we design and create custom fixtures to hold everything in place.

Although we’re experts in welding, we also specialize in welding alternatives like rivets and mechanical fasteners. Some of the strongest and most sophisticated designs don’t require welding at all.

Welding Design & Engineering Best Practices

Designing for weldments requires balancing structural integrity, manufacturability, and precision to ensure high-quality results while minimizing defects, distortion, and unnecessary rework.

1. Optimize Weld Joint Design

Choosing the right joint configuration is critical to achieving strong, reliable welds with minimal material waste. Common weld joint types include:

- Butt Joints – Ideal for joining two flat sheets along their edges with minimal excess material.

- Lap Joints – Provide high strength and ease of welding, commonly used in spot and seam welding applications.

- Fillet Joints – Suitable for corner, T, and lap joints, often used in structural and enclosure applications.

- Plug & Slot Welds – Best for joining overlapping sheets while maintaining a flush outer surface.

2. Minimize Heat Distortion & Warping

- Use the lowest heat input necessary. Precision TIG or resistance welding methods generate less heat than MIG welding.

- Apply stitch welding instead of continuous beads. Intermittent welds reduce heat buildup.

- Utilize backstepping techniques. Welding in a non-linear sequence distributes stress evenly.

- Incorporate heat sinks or cooling jigs. Metal blocks or copper backing bars help dissipate heat and maintain dimensional accuracy.

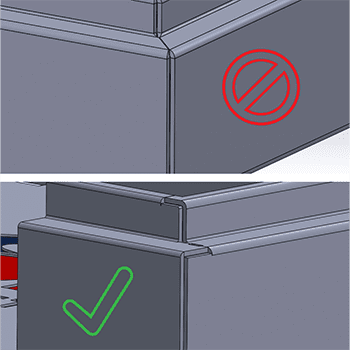

3. Use Alignment Features for Precision Fit-Up

- Cleco holes or tab & slot features. Pre-positioned alignment holes or interlocking tabs ensure precise assembly.

- Custom fixtures. Rigid welding jigs prevent parts from shifting during the welding process.

- Pre-bending or pre-compensating for shrinkage. Designs should account for material contraction after cooling.

If you need weldments for your next project, rely on us to produce the best welds without worrying about uneven seams, heat distortion, or misalignment. Request a quote today!

Sheet Metal Weldment Techniques FAQ

Welding is a fabrication method where smaller parts are fused together to create larger pieces. It has a long history, dating back to the Bronze Age and even blacksmithing. Today, it's used in various industries to produce parts for cars, aircraft, buildings, and more.

Approved Sheet Metal employs three key weldment techniques: spot welding, seam welding, and plug welding. These methods are tailored to specific applications and help streamline the creation of assembled parts.

Spot welding involves using electrical current to fuse layers of sheet metal together. It's highly efficient and cost-effective, making it a popular choice for high-volume production. Common applications include electronics, solar panels, and automobile parts.

Seam welding is ideal for creating smooth, continuous joints between metal sheets. It's commonly used in applications requiring airtight or watertight seals, such as marine components, tanks, and pressure vessels. Seam welding is faster than spot welding and doesn't require filler material.

Plug welding, also known as rosette welding, is a versatile method used in the automotive industry. It involves creating coin-like deposits on overlapping sheet metal by cutting holes into one sheet and layering it over the other. This technique is highly durable and suitable for manufacturing hot rods and auto repairs.