Last updated on March 19th, 2025 at 08:24 am

When customers request a quote for sheet metal fabrications, they provide a flat design and we fabricate it into a 3D part. There are all sorts of considerations we take into account when we go from 2D to 3D.

Corner measurements are one of those quirks that we address on just about every part we make. Most of the time, the corners as designed will have a gap that needs to be welded closed.

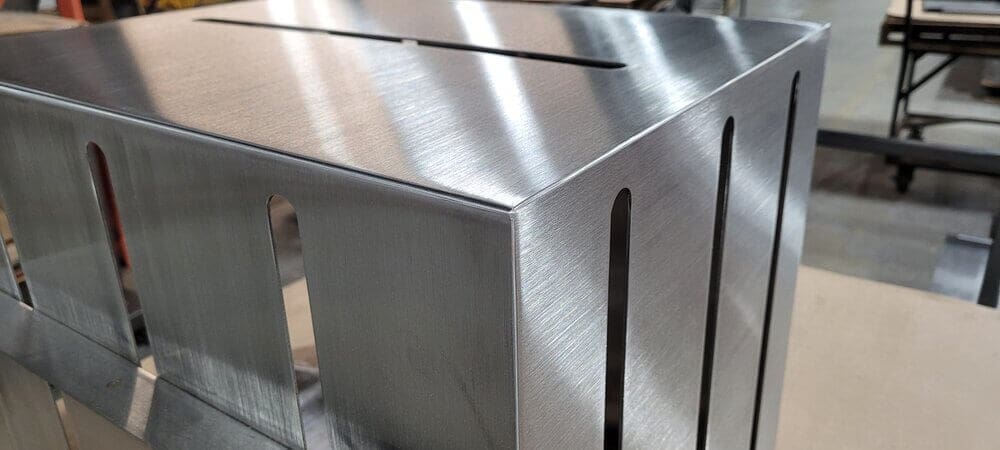

It’s our job as your trusted sheet metal shop to ensure that your corners are strong, precise, and aesthetically pleasing—and we take that job very seriously.

Table of Contents

- 1 Why Is Corner Construction So Important?

- 2 Sheet Metal Corner Joint Types & Their Applications

- 3 Approved Sheet Metal’s Proven Approach to Corner Construction

- 4 Sheet Metal Part Design for Manufacturing Tip

- 5 Metal Fabrication Corner Construction FAQ

- 5.0.1 Why is proper corner construction crucial in sheet metal fabrications?

- 5.0.2 How does Approved Sheet Metal ensure high-quality corners in every fabrication?

- 5.0.3 Why do aluminum parts require a different corner construction approach?

- 5.0.4 How do you handle corner construction for steel and stainless steel parts?

- 5.0.5 Are there additional techniques you use to enhance corner strength and weld aesthetics?

Why Is Corner Construction So Important?

Not every shop is as obsessive about corner prep as we are. But when shops fail to prepare corners properly for welding, parts can end up out of tolerance, with weak and wavy corners that are prone to breakage. These issues are not in line with our quality standards. Your sheet metal fabrications need to stand the test of time without cracking under pressure.

Want to know how we guarantee high-quality corners every time? Take a look at our proven approach to corner construction.

Sheet Metal Corner Joint Types & Their Applications

Selecting the right corner joint for your custom metal fabrication is crucial to ensuring structural integrity, durability, and ease of manufacturing. Different joint types offer varying levels of strength, weldability, and suitability for different applications. Here’s a breakdown of the most common corner joints and where they are best used:

1. Butt Joint

A butt joint is the simplest type of corner joint, where two pieces of metal meet edge-to-edge and are welded together.

✅ Best For:

- Applications requiring a clean, flush surface.

- Thin sheet metal where minimal material overlap is needed.

⚠️ Considerations:

- Requires precise alignment for strong welds.

- May need reinforcement for high-stress applications.

2. Lap Joint

A lap joint involves overlapping two pieces of sheet metal and welding along the edge where they overlap.

✅ Best For:

- Enhancing strength in thin-gauge sheet metal.

- Applications where welding on one side is preferred.

⚠️ Considerations:

- Can create uneven surfaces if not properly controlled.

- May trap moisture or contaminants, requiring post-weld cleaning.

3. Corner Joint (Closed or Open)

Corner joints are formed when two metal sheets meet at a 90-degree angle. These joints can be either open (with a gap to be filled with welding material) or closed (where the edges touch completely).

✅ Best For:

- Enclosures, boxes, and frames requiring clean aesthetics.

- High-strength applications where full penetration welding is needed.

⚠️ Considerations:

- Heat input can cause warping, especially in aluminum.

- Proper fixturing is required to maintain alignment during welding.

4. Fillet Welded Corner Joint

A fillet weld is applied to the outside of a corner joint, fusing the two surfaces together without requiring a full penetration weld.

✅ Best For:

- Applications where moderate strength is needed.

- Faster welding process compared to full penetration welds.

⚠️ Considerations:

- May not provide the same strength as a full penetration weld.

- Requires precise welding technique to avoid excess buildup.

5. Miter Joint

A miter joint is formed by cutting the metal edges at a 45-degree angle before welding, creating a seamless 90-degree corner.

✅ Best For:

- Aesthetic applications requiring a smooth, professional appearance.

- Architectural and decorative metal fabrications.

⚠️ Considerations:

- More difficult to align and weld compared to other joints.

- Weaker than other joints if not properly reinforced.

Choosing the Right Corner Joint

The right corner joint depends on your part’s strength requirements, material type, and fabrication process. For instance, butt joints and fillet-welded joints are great for simple enclosures, while miter joints are ideal for aesthetic applications. If welding is a concern, lap joints or mechanical fastening methods can be explored as alternatives.

Approved Sheet Metal’s Proven Approach to Corner Construction

Our approach to corner construction is largely dependent on part material. The heat from the welding process affects aluminum differently than steel or stainless steel, so these common sheet metal materials require different approaches:

- Aluminum. Aluminum parts call for open corner welds. Because aluminum isn’t as rigid as steel or stainless steel, it can’t stand up to heat in the same way. If we were to blast an aluminum part with too much heat, we could blow a hole in the material. So instead of risking that costly mishap, we rely on filler rods, which are just simple metal rods, to aid in the process. Filler rods help to reinforce and strengthen the corners. We melt them to the appropriate temperature before attaching them to the base of the part.

- Steel or stainless steel. With steel and stainless steel parts, we can perform a full outside weld. In this scenario, we only cut one side of the corner, so there is more material there than with aluminum, which means we need only a minimal amount of filler rod. Then, we fuse the metal together, creating a strong corner.

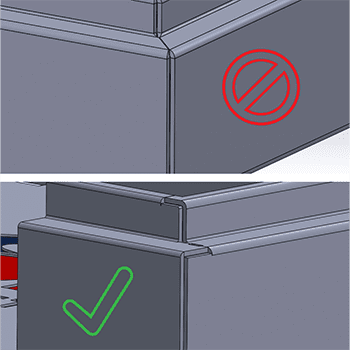

In addition to these approaches, we also leverage reliable techniques like interlocking tabs to strengthen corners and ensure beautiful welds every time.

Don’t let just any sheet metal shop construct your corners for you. Request a quote from Approved Sheet Metal and we promise we’ll never cut corners on cutting corners. 😉

Metal Fabrication Corner Construction FAQ

Corner construction plays a vital role in ensuring the durability and strength of sheet metal parts. When corners are not properly prepared for welding, it can lead to parts being out of tolerance, weak, and susceptible to breakage. Our obsessive attention to corner prep ensures that your fabricated parts meet high-quality standards and can withstand the test of time without compromising under pressure.

Our approach to corner construction varies based on the material of the part. For aluminum parts, we utilize open corner welds due to aluminum's sensitivity to excessive heat. To avoid damaging the material, we use filler rods to reinforce and strengthen corners, ensuring a solid weld without compromising the integrity of the aluminum. In the case of steel or stainless steel parts, we perform full outside welds, using minimal filler rod to fuse the metal together and create robust corners.

Aluminum is less rigid than steel or stainless steel, making it sensitive to high levels of heat during the welding process. To prevent the risk of blowing a hole in the material, we employ open corner welds with filler rods. These filler rods reinforce the corners and provide the necessary strength while avoiding excessive heat exposure.

For steel and stainless steel parts, we perform full outside welds. This involves cutting only one side of the corner, leaving more material compared to aluminum. With the addition of a minimal amount of filler rod, we fuse the metal together to create strong corners. This approach is effective in maintaining the structural integrity of the parts while ensuring aesthetically pleasing welds.

Yes, in addition to the corner construction approaches mentioned, we also implement reliable techniques like interlocking tabs. These tabs further strengthen corners and contribute to achieving beautiful welds consistently. Our commitment to detail and precision ensures that every aspect of corner construction is optimized for the best possible results in your sheet metal fabrications.