Hardware Insertion in Sheet Metal Parts

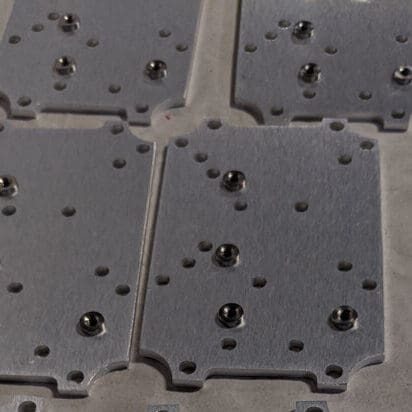

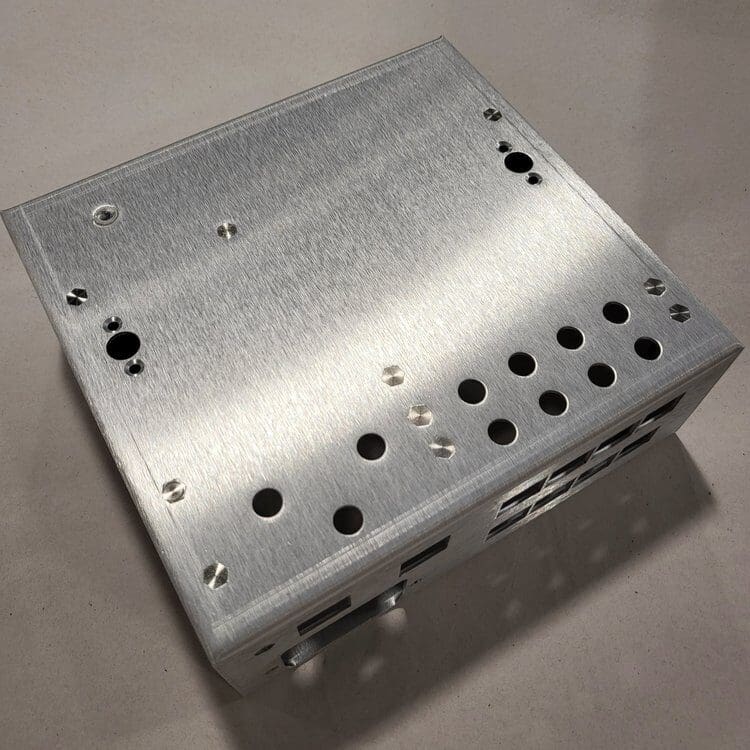

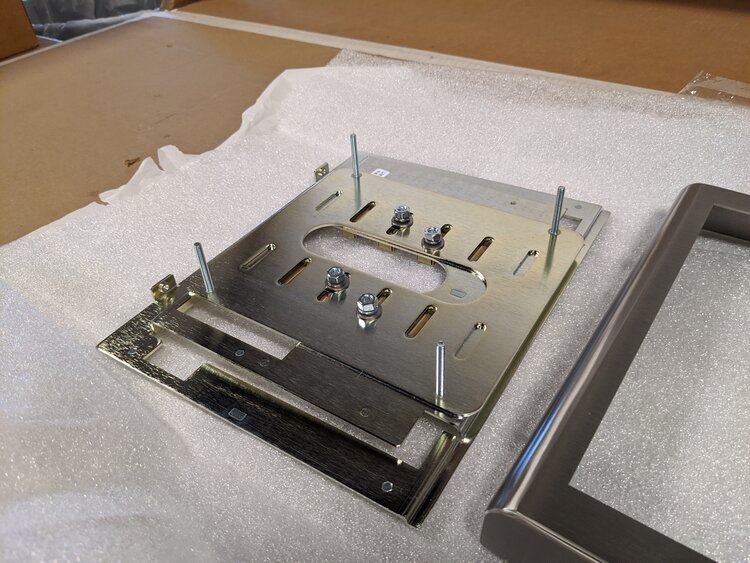

Hardware insertion of custom precision sheet metal parts is a process that requires special tools and experience. The first step is to create a die, which is a negative mold of the desired shape. The die is then used to cut the metal into the desired shape. Next, the hardware is inserted into the metal using a press. This step must be done carefully in order to avoid damage to the hardware or the metal. Finally, the metal is trimmed and finished to create a clean, professional appearance. hardware insertion of custom precision sheet metal parts is a complex process, but with the help of a skilled fabricator like Approved Sheet Metal, it can be done quickly and correctly.

Approved Sheet Metal has hardware insertion capabilities in-house so you can get precisely hardware inserted parts FAST. Our hardware insertion operators have 15+ years of experience in inserting hardware into prototype and low volume production quantities. In addition to hardware insertion, other capabilities that Approved Sheet Metal has extensive experience in include:

Check out the gallery below to see what we can do for you!

Frequently Asked Questions (FAQ)

What is your lead time for sheet metal parts?

Standard shipping for punch-formed parts is 7-10 days, with expedites available!

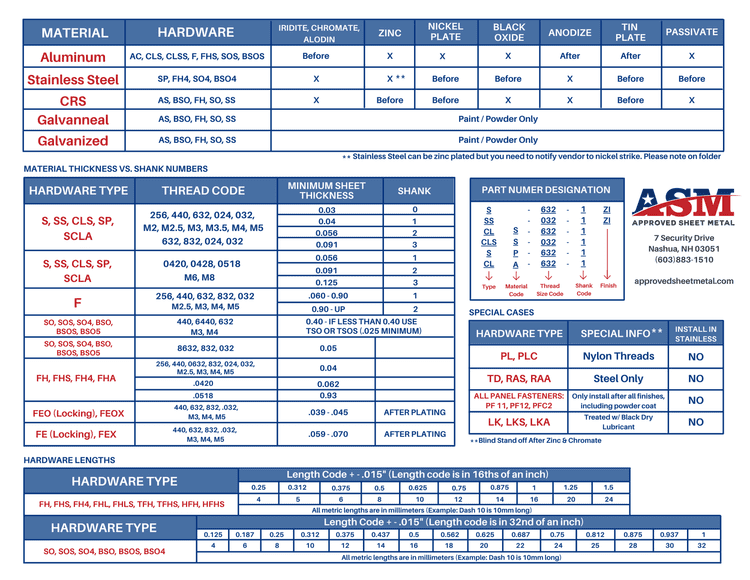

What types of hardware can you insert into sheet metal parts?

Standoffs, Pins, Studs, Lock Nuts, Micro Pins, Non-Flush Studs, Flush-Head Pins, Blind Fasteners, Self-Clinching Lock Nuts and much more.

What considerations should I think about when designing parts?

There are ways to design parts, and specific features, that will help reduce back-and-forth and ensure that you get what you need out of your part. Take a look at our Sheet Metal Design for Manufacturing eBook to see best practices - See the eBook