Last updated on March 10th, 2025 at 09:47 am

Now more than ever, the medical community is tasked with providing outstanding care to patients worldwide.

Medical experts rely on top-quality devices to do their jobs well, and these products require high-precision fabricated parts—our specialty here at Approved Sheet Metal.

We're proud that Fortune 500 medical device companies trust us with their sheet metal fabrication projects. From our custom fabrication shop in Hudson, New Hampshire, we fabricate various precision sheet metal medical device components and assemblies for manufacturers worldwide.

Our team of mechanics, laser operators, and programmers is uniquely equipped to serve the medical device industry. In 2021, we acquired Nashua Fabrication, a company specializing in tubular stainless steel parts with a focus on pharmaceutical and biomedical applications.

We have 30+ years of specialized sheet metal fabrication experience and are ready to take your medical device manufacturing process to the next level.

Table of Contents

- 1 Common Parts We Fabricate for the Medical Device Industry

- 2 Common Materials for Medical Devices: Stainless Steel and Aluminum

- 3 Surface Finishing Techniques for Medical Devices

- 4 Fabrication Capabilities That Support the Medical Device Industry

- 5 Sheet Metal Design for Manufacturing

- 6 Sheet Metal Fabrication for Medical FAQ

- 6.0.1 What types of parts do you commonly fabricate for the medical device industry?

- 6.0.2 What materials are commonly used in medical device fabrication?

- 6.0.3 What fabrication capabilities does Approved Sheet Metal offer for the medical device industry?

- 6.0.4 What makes Approved Sheet Metal stand out in serving the medical device industry?

- 6.0.5 What advantages do stainless steel 316 and aluminum 5052 offer in medical device fabrication?

Common Parts We Fabricate for the Medical Device Industry

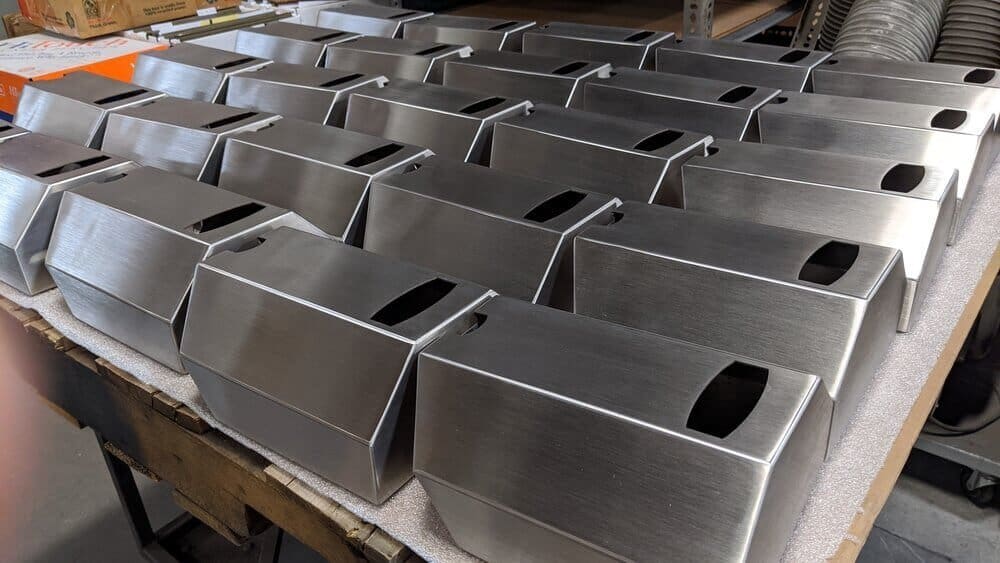

Whether you bring us hand sketches or detailed prints, we can transform your ideas into tangible precision sheet metal parts. Here are several parts we commonly fabricate for the medical device industry:

- Covers

- Custom medical carts

- Enclosures

- IV equipment

- Cabinets

And don’t forget about our signature custom metal fabrication for the medical industry: custom stainless steel tubular frames.

Applications for these frames include supply carts, trays, chassis, test tube racks, and baskets —all of which we can fabricate quickly and flawlessly. If your medical device company requires sheet metal parts fast, our team of seasoned experts can get your parts out the door quickly and right the first time.

Common Materials for Medical Devices: Stainless Steel and Aluminum

The two materials most commonly used for fabricating medical device parts are stainless steel and aluminum.

Stainless steel 316

Stainless steel 316 is an ideal material in the medical device industry, and for a good reason. This high-strength metal is extremely corrosion-resistant and can withstand the high heat and harsh chemicals used in medical sterilization processes without distorting. It also has a polished surface—perfect for applications that must be sterile at all times.

Aluminum 5052

While aluminum 5052 isn't the strongest aluminum available, it is common in the medical device industry for its excellent weldability, formability, and rust resistance.

When we work on your custom metal fabrication, we'll walk you through your options and make sure you're using the material that best fits your needs.

Surface Finishing Techniques for Medical Devices

In the medical industry, surface finish is just as critical as material selection. The right finish improves corrosion resistance, sterilization compatibility, and durability while ensuring the safety and longevity of medical devices. Below are common surface finishing techniques used in sheet metal fabrication for medical applications:

1. Passivation for Stainless Steel

Purpose: Enhances corrosion resistance by removing free iron from the surface.

- Ideal for 316 stainless steel, making it more resistant to harsh sterilization chemicals.

- Ensures biocompatibility by eliminating potential contaminants.

- Often required for FDA and ISO 13485 compliance in medical device manufacturing.

2. Electropolishing for Ultra-Smooth Surfaces

Purpose: Creates a smooth, mirror-like surface that resists bacterial adhesion.

- Removes microscopic imperfections that can harbor contaminants.

- Reduces surface roughness (Ra) to meet medical hygiene standards.

- Commonly used for surgical instruments, implantable devices, and stainless steel trays.

3. Anodizing for Aluminum Components

Purpose: Increases wear resistance, corrosion resistance, and visual identification.

- Type II anodizing (color anodizing) is useful for color-coded emergency medical devices.

- Type III (hard anodizing) improves abrasion resistance, ideal for long-term durability.

- Commonly applied to aluminum enclosures, surgical tools, and diagnostic equipment.

4. Powder Coating for Durability & Customization

Purpose: Adds a protective, durable, and aesthetically pleasing coating.

- Provides a non-porous surface that withstands frequent cleaning and sterilization.

- Allows for custom branding and identification in medical device casings.

- Can be applied to medical carts, enclosures, and cabinetry.

5. Bead Blasting for Matte Finishes

Purpose: Creates a uniform, non-reflective matte surface.

- Reduces glare in surgical environments.

- Used to prepare surfaces before coating or anodizing.

- Common for stainless steel housings and aluminum panels.

Choosing the Right Surface Finish

The ideal finishing technique depends on your application’s requirements, including:

- ✅ Corrosion resistance → Passivation, anodizing

- ✅ Sterilization compatibility → Electropolishing, passivation

- ✅ Aesthetic and branding → Anodizing, powder coating

- ✅ Durability and wear resistance → Hard anodizing, powder coating

By selecting the right finishing process, you ensure that your medical device components not only meet industry standards but also enhance performance, longevity, and patient safety.

Fabrication Capabilities That Support the Medical Device Industry

At Approved Sheet Metal, we’re dedicated to our craft and committed to supporting the medical device industry by fabricating components and assemblies that meet the most stringent requirements.

Our experienced team has a robust set of skills to ensure we meet your needs. Our capabilities include:

- In-house sheet metal forming, so you can get precisely formed parts FAST

- In-house laser cutting with experts leveraging their 15+ years of experience

- A punch press in-house that can yield tolerances of +/- 0.003"

- Various in-house welding services, including MIG, TIG, and spot welding

- Sheet metal assemblies that can ship out in 10-14 days, with expedited options available

- Color-anodizing services, which are especially useful for emergency features on medical devices

We can fabricate single parts or entire assemblies. Should your project require it, we can combine capabilities, such as welding and hardware insertion.

If you're in search of a custom fabrication shop that always delivers for the medical device industry, give us a shot on your next project.

Sheet Metal Fabrication for Medical FAQ

We commonly fabricate a variety of precision sheet metal parts for the medical device industry, including covers, custom medical carts, enclosures, IV equipment, and cabinets. Additionally, our signature offering is custom stainless steel tubular frames used for applications such as supply carts, trays, chassis, test tube racks, and baskets.

The two most common materials we use for fabricating medical device parts are stainless steel and aluminum. Stainless steel 316 is favored for its exceptional corrosion resistance, high strength, and ability to withstand sterilization processes. Aluminum 5052 is chosen for its weldability, formability, and rust resistance, making it a valuable choice in the medical device industry.

Approved Sheet Metal offers a range of fabrication capabilities to support the medical device industry's stringent requirements:

- In-house sheet metal forming for precise parts, delivered quickly.

- In-house laser cutting with 15+ years of expert experience.

- Punch press capabilities with tolerances of +/- 0.003".

- Various in-house welding services, including MIG, TIG, and spot welding.

- Rapid fabrication of sheet metal assemblies in 10-14 days, with expedited options.

- Color-anodizing services, particularly useful for emergency features on medical devices.

- We can fabricate single parts or complete assemblies and can combine capabilities as needed, including welding and hardware insertion.

Approved Sheet Metal stands out in the medical device industry due to our extensive experience, expertise, and dedicated team. We've gained the trust of Fortune 500 medical device companies. Our specialization in precision fabrication, use of high-quality materials like stainless steel 316 and aluminum 5052, and comprehensive capabilities, including in-house forming, laser cutting, welding, and expedited shipping, set us apart as a reliable partner for elevating the medical device manufacturing process.

Stainless steel 316 is an ideal choice for medical device fabrication due to its exceptional corrosion resistance and ability to withstand high heat and harsh chemicals used in sterilization processes. Its polished surface meets the sterilization requirements of medical applications. On the other hand, aluminum 5052 is favored for its weldability, formability, and rust resistance. Both materials are carefully chosen to meet the unique demands of the medical industry and ensure the longevity and functionality of medical devices.