Last updated on December 17th, 2024 at 02:53 pm

In sheet metal fabrication, sometimes an RFQ for a seemingly simple part can return an unexpectedly high quote, leaving customers wondering why. While sometimes certain complex features or exotic materials are to blame, one of the most surprising contributors is lot charges—minimum fees required by vendors in manufacturing.

These mandatory charges apply whether you need one part or one hundred, and single prototypes can be particularly costly. One basic bracket requiring finishing can suddenly jump to hundreds of dollars in cost, driven by lot charges alone.

Understanding lot charges and implementing smart strategies can help you optimize costs, reduce lead times, and better plan your projects. Read on to learn how to navigate—and potentially avoid—lot charges in your metal fabrication projects.

Table of Contents

What Are Lot Charges?

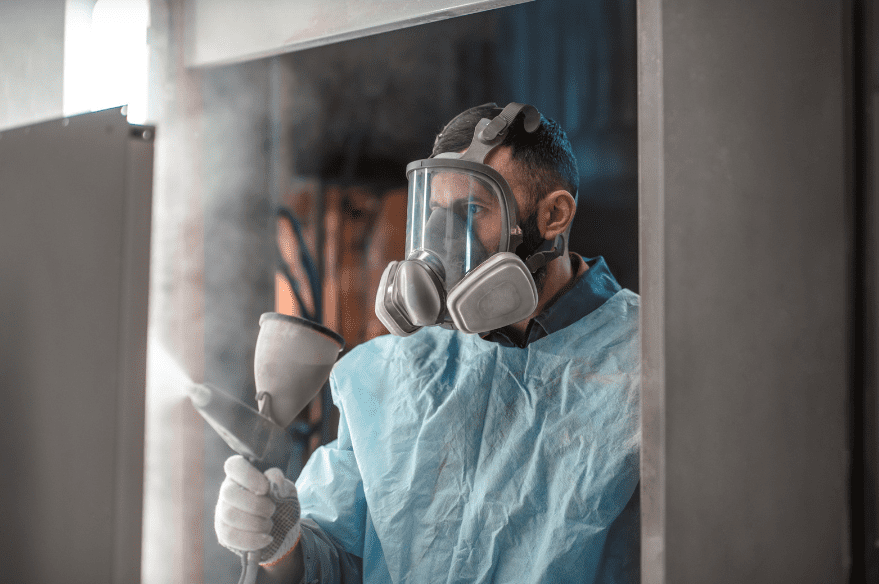

When your parts require outside finishing services like plating, powder coating, or silk screening, our vendors apply industry-standard minimum fees known as lot charges. Though our in-house fabrication services don't include these fees, they can become a significant factor in a part’s pricing when specialized finishes are needed.

These baseline charges are how vendors offset their setup costs, administrative fees, and operational overhead. While the actual finishing cost per part may be minimal, lot fees can still be significant. Consider a single part that needs painting: the coating itself might cost just a few dollars, but the lot charge could add hundreds to your total. The numbers add up quickly when your design requires multiple finishing processes, since each vendor applies their own minimum fee, turning what seems like a simple project into a surprisingly costly one.

How Much Are Lot Charges for Different Finishes?

Every finishing process has a different lot charge structure. Wet paint, for instance, typically has one of the highest lot charges, and often includes other fees like paint charges. Powder coating is typically less than wet paint, and customers who would like to avoid high lot charges for wet paint should consider powder coating as an alternative.

Basic plating processes will often have relatively low lot charges, but specialized processes like electropolishing can have higher fees. Other common processes like silk screening and bead blasting include lot fees that vary from vendor to vendor.

4 Ways to Manage Your Lot Charges

Lot charges are a fact of life in manufacturing, but you can use several strategies to help manage their impact on your custom metal fabrication project:

- Order Multiple Pieces: When a lot charge is spread across several pieces, the per unit cost drops significantly. Even increasing your order from one part to three parts can help to achieve significantly better cost efficiency. If you expect to need more parts in the future, it is often an ideal strategy to simply order them upfront.

- Evaluate the Necessity of Your Finish: If you’re leveraging our sheet metal prototyping services to test fit and function with a single part, a finishing process may not be necessary. Eliminating a non-essential finish can significantly reduce costs without compromising your prototype.

- Consider Alternative Finishes: If a finish is necessary, you may be able to use a comparable alternative finish that has lower lot charges. For example, wet paint typically has high lot charges, and powder coating may provide the necessary results with lower fees.

- Communicate With Your Fabrication Company: If you have pricing concerns, discuss them as soon as possible with your fabricator. We can often suggest alternative approaches, or we can help to combine your order with others that are shipping to the same vendor in order to minimize the lot charges.

Worried About Your Pricing? Talk to Us Today

Lot charges are a standard industry practice, and they help ensure manufacturers can provide their service for the long-term. Even so, we understand that they can lead to confusion around high quotes.

We always want customers to understand their quotes and what they can do to reduce their costs. If you’re looking to start a new project soon and want to minimize your pricing, talk to us today. We are always ready to help you optimize your project for cost by strategizing on lot charges, offering DfM advice, and more.

Request a quote and start collaborating with Approved Sheet Metal!