Last updated on April 11th, 2025 at 07:41 am

Metal fabrication comprises a number of processes used to manipulate flat metal into various shapes and structures. Forming, bending, cutting, punching, stamping, shearing, welding, and assembling are all types of metal fabrication.

Working in dedicated metal fabrication shops, expert metal fabricators transform raw plate metal, cast metal, metal tubing, and expanded metal into finished products for a variety of uses.

Table of Contents

- 1 Metal Fabrication Categories

- 2 Tolerancing and GD&T Considerations

- 3 Sheet Metal Design for Manufacturing

- 4 Common Applications for Precision Fabrication

- 5 Common Types of Metal Used in Precision Metal Fabrication

- 6 Our Precision Metal Fabrication Capabilities

- 7 Precision Metal Fabrication Technologies

- 8 Recommended Default Sheet Metal Tolerances

- 9 Metal Fabrication FAQ

- 9.0.1 What does metal fabrication involve, and what processes does it include?

- 9.0.2 What are the four main categories of metal fabrication?

- 9.0.3 What are some common applications for precision sheet metal fabrication?

- 9.0.4 Which types of metals are commonly used in precision metal fabrication?

- 9.0.5 What are some key processes involved in precision metal fabrication?

- 9.0.6 How does your metal fabrication process ensure precision and quality?

- 9.0.7 What is involved in the finishing and assembly stages of metal fabrication?

Metal Fabrication Categories

Let’s explore the four main categories of metal fabrication.

Structural Fabrication

Structural fabrication is a specialized sub-category of metal fabrication that focuses on the creation of large-scale structural components and assemblies used in various industries, including construction, manufacturing, and infrastructure development. This process involves the transformation of raw metal materials, such as steel, into precisely crafted structural elements like beams, columns, trusses, and frames that form the skeletal framework of buildings, bridges, industrial facilities, and other structures. Structural fabrication is crucial for ensuring the stability, durability, and safety of these constructions.

Industrial fabrication

Industrial fabrication is a specialized sub-category of metal fabrication that focuses on the manufacturing of various metal components and assemblies used in industrial applications. This field encompasses a wide range of processes and techniques, all geared towards producing custom metal parts and equipment tailored to the specific needs of industrial sectors such as manufacturing, energy production, aerospace, and automotive industries. Industrial fabrication involves the utilization of various metals, including steel, aluminum, and stainless steel, to create parts like machinery components, conveyor systems, storage tanks, and specialized tooling.

Commercial fabrication

Commercial fabrication is a sub-category of metal fabrication that specializes in crafting metal products and structures for commercial enterprises and businesses. Unlike industrial fabrication, which often involves large-scale production for heavy industries, commercial fabrication caters to a diverse range of businesses in sectors like retail, hospitality, healthcare, and office spaces. This field encompasses the creation of custom-made fixtures, furnishings, and architectural elements that enhance the functionality and aesthetics of commercial spaces. Common examples of commercial fabrication projects include storefront facades, decorative metalwork, custom signage, display fixtures, and interior architectural elements like railings and staircases.

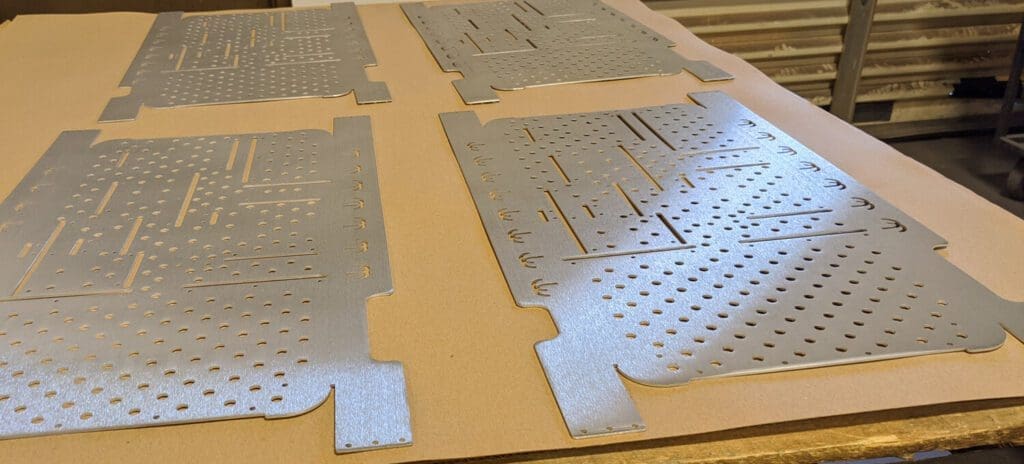

Precision metal fabrication

Precision metal fabrication is reserved for applications where part functionality depends on a high degree of accuracy. Precision parts may have complex features and often require a polished appearance. The high level of detail demanded by this fabrication type makes it the most meticulous of the four.

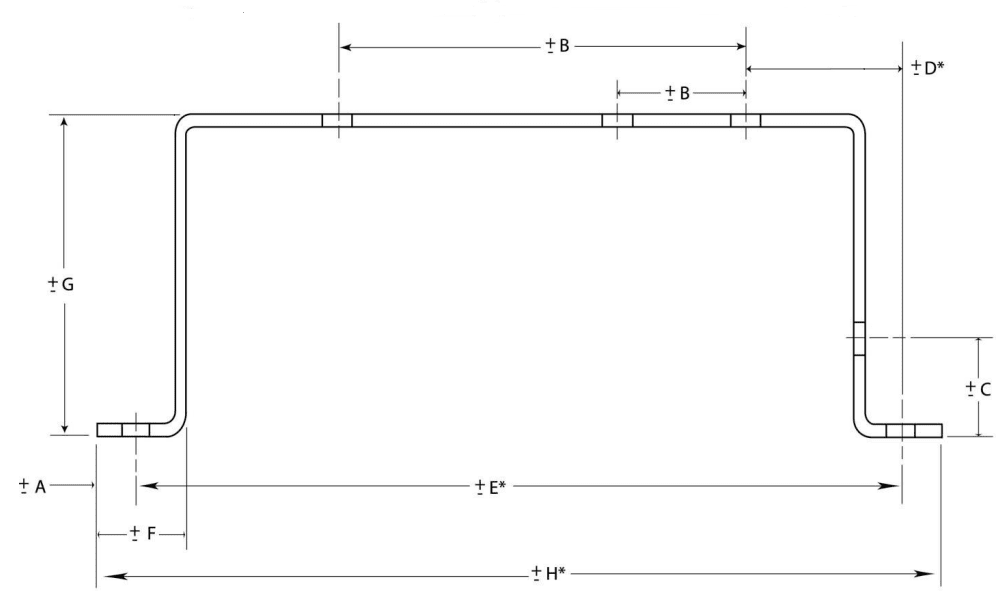

Tolerancing and GD&T Considerations

For mechanical engineers, precision isn’t just a preference—it’s a requirement. Whether you’re designing enclosures, brackets, or high-performance assemblies, understanding how tolerances and GD&T apply to sheet metal fabrication is essential to ensuring functional, manufacturable parts.

Typical Sheet Metal Tolerances

| Feature | Standard Tolerance |

|---|---|

| Laser-cut dimensions | ±0.005" to ±0.010" |

| Bend angle | ±1° |

| Bend length | ±0.015" |

| Hole-to-edge or hole-to-bend distance | ±0.010" to ±0.030" |

| Form height/depth | ±0.015" to ±0.030" |

Design Tips for Tolerancing

- Avoid unnecessarily tight tolerances: Over-tolerancing increases costs, slows down production, and may require manual inspection or rework.

- Use functional tolerances: Tolerances should be driven by performance needs. For example, a laser-cut vent doesn’t need the same tolerance as a mounting hole for a precision sensor.

- Be consistent with features: Hole patterns, tabs, and fastener locations should follow a logical, uniform spacing to minimize variation during forming.

GD&T in Sheet Metal

While Geometric Dimensioning & Tolerancing (GD&T) is more common in machined parts, it’s increasingly being used in sheet metal designs where precision is critical.

Common GD&T callouts used in sheet metal include:

- Flatness – ensures proper mating or assembly of base surfaces

- Position – controls location of mounting holes and cutouts

- Perpendicularity – critical for flanges or formed tabs

- Parallelism – used when panels or bracket arms must align

Tip: When using GD&T, be sure to align your feature control frames with the fabrication process. Over-specifying can cause confusion and delays during quoting or inspection.

Discuss Early, Avoid Rework

We always recommend involving our engineering team early in the design process—especially for parts that will be used in assemblies or functional systems. By reviewing tolerances and GD&T callouts together, we can:

- Recommend achievable tolerances for each process

- Flag over-constrained dimensions that could increase cost or complexity

- Suggest alternate features or joining methods for better repeatability

At Approved Sheet Metal, we dedicate our services to precision metal fabrication.

Common Applications for Precision Fabrication

Precision sheet metal fabrication is a versatile manufacturing process used to create a wide range of components and products with high accuracy and consistency. Some common applications of precision sheet metal fabrication include:

- Electronics Enclosures: Precision sheet metal fabrication is often used to manufacture enclosures and chassis for electronic devices, such as computer servers, control panels, and telecommunications equipment. These enclosures protect sensitive electronic components from environmental factors while providing thermal management.

- Aerospace Components: The aerospace industry relies on precision sheet metal fabrication to produce critical components like aircraft fuselages, wings, and structural parts. These parts need to meet strict safety and performance standards.

- Automotive Parts: Precision sheet metal fabrication is used in the automotive industry to manufacture components such as car bodies, frames, brackets, and exhaust systems. These parts require precision to ensure safety and performance.

- Medical Equipment: Many medical devices and equipment, such as MRI machines, surgical instruments, and diagnostic tools, are manufactured using precision sheet metal fabrication to ensure accuracy, durability, and hygiene.

- HVAC (Heating, Ventilation, and Air Conditioning): Ductwork, ventilation systems, and HVAC components are commonly fabricated with precision sheet metal to ensure efficient and reliable climate control in buildings.

- Appliance Manufacturing: Household appliances like ovens, refrigerators, and washing machines often incorporate precision sheet metal components for their structural integrity and aesthetics.

- Consumer Electronics: Products like smartphones, tablets, and laptops often contain precision sheet metal parts in their casings, frames, and internal structures.

- Lighting Fixtures: Precision sheet metal fabrication is used to create custom lighting fixtures for residential, commercial, and industrial applications.

- Custom Metal Cabinets and Enclosures: Many industries require custom metal cabinets and enclosures for housing various equipment and machinery. Precision sheet metal fabrication allows for tailored solutions.

- Architectural Metalwork: Precision sheet metal fabrication is used in architectural applications, including decorative metalwork, railing systems, and façade cladding in commercial and residential buildings.

- Food Service Equipment: Precision sheet metal is used in the manufacturing of commercial kitchen equipment such as sinks, countertops, and food preparation surfaces.

- Telecommunications Equipment: Telecommunications infrastructure relies on precision sheet metal components for housing and mounting equipment like servers, routers, and switches in data centers and network facilities.

Common Types of Metal Used in Precision Metal Fabrication

Our fabricators work primarily with four standard metals, using sheets measuring up to ¼” thick:

Our Precision Metal Fabrication Capabilities

Our highly skilled team performs an array of precision metal fabrication operations, including:

Laser cutting

In laser cutting, a high-powered laser beam is directed onto the material's surface, generating intense heat that melts or vaporizes the material along the desired cutting path. This process offers exceptional precision, allowing for intricate and complex designs to be cut with remarkable accuracy. Moreover, laser cutting's non-contact nature eliminates the need for traditional cutting tools, which can wear out and require frequent maintenance, resulting in cost-effective and efficient production processes. Additionally, the versatility of laser cutting extends to a wide range of materials, including metals, plastics, ceramics, and even textiles, making it a go-to choice for industries demanding both precision and adaptability in their fabrication processes.

Punching

Punching is a versatile metal fabrication technique known for its speed and efficiency in creating accurately positioned holes, notches, and complex shapes in sheet metal. This method relies on the force applied by the punch and die set, which can vary in size and shape to accommodate a wide range of designs and materials. CNC punching machines have revolutionized the process, enabling precise and automated production of intricate patterns and geometries. Furthermore, punching is not limited to holes alone; it can also be employed for embossing, deburring, and forming operations, making it a multifunctional process suitable for a variety of industries, from automotive and aerospace to electronics and construction.

Forming

Forming, as a metal fabrication technique, relies on the application of controlled force to reshape sheet metal into desired configurations. The use of a press brake, which features precision tooling, ensures consistency and repeatability in producing complex geometries with tight tolerances. This method is indispensable in manufacturing industries where components demand a high degree of precision and uniformity, such as aerospace, automotive, and appliance manufacturing. Beyond bending, forming can also encompass deep drawing processes, where flat sheets are transformed into three-dimensional parts like cylinders and cups, further showcasing its versatility in creating intricate and functional components.

Hardware insertion

Hardware insertion is a crucial step in the metal fabrication process that enhances the functionality and versatility of fabricated parts. The creation of a precise die ensures that the hardware component fits seamlessly into the metal, ensuring a secure and durable connection. This process is commonly employed in various industries, including manufacturing, automotive, and electronics, where the assembly of components with fasteners, studs, or threaded inserts is essential for the final product's performance. Furthermore, the meticulous trimming and finishing of the metal after hardware insertion not only enhances the aesthetic appeal but also guarantees that the components meet the desired specifications and quality standards, ensuring a seamless integration of hardware into the fabricated parts.

Welding

Welding, as a metal fabrication process, is indispensable for creating strong and durable connections between metal parts. It relies on the application of intense heat to achieve the melting and fusion of adjacent metal surfaces, resulting in a robust and structurally sound bond. The choice of welding method depends on factors such as the type of metals being joined, the desired joint strength, and the specific application requirements. For instance, MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding are favored for their precision and versatility, making them ideal for applications demanding fine craftsmanship and minimal distortion. On the other hand, spot and resistance welding are frequently used for high-speed production processes, such as automotive manufacturing, where the emphasis is on efficiency and consistency in creating secure welds. Welding plays a pivotal role in a multitude of industries, including construction, aerospace, and shipbuilding, ensuring the structural integrity and reliability of a wide range of products and structures.

Finishing

We offer a number of in-house finishing services. Powder coating, a versatile and widely used method, not only enhances the aesthetics of sheet metal parts but also provides a robust layer of protection against rust, corrosion, and wear. Silk screening adds a personalized touch, allowing us to apply logos, graphics, or important instructions directly onto the sheet metal, ensuring clarity and branding consistency. Furthermore, our plating and color anodizing options cater to various industries and applications, offering a range of finishes that not only improve the appearance of the sheet metal but also enhance its resistance to environmental factors, making our finished sheet metal products both visually appealing and highly functional. These in-house finishing services complement our sheet metal fabrication capabilities, providing clients with a one-stop solution for their precision sheet metal needs.

Assembly

We can also create your assemblies in our shop. Customers who hire us for assembly services benefit from completing their production workflow with a team that knows their parts inside and out.

Precision Metal Fabrication Technologies

We leverage three key technologies when performing metal fabrication services.

Automation

As a team that champions innovation, we incorporate automation into our metal fabrication processes whenever possible. Many of our state-of-the-art machines include sophisticated programming features that allow us to run operations with limited human involvement.

CAD software

Computer-aided design (CAD) software is an indispensable tool for designing parts for metal fabrication. Engineers use CAD to create and revise designs, identify weaknesses in a design, produce 3D models of a part, and communicate programming instructions to fabrication machinery.

Machinery

We use top-of-the-line machines to run various metal fabrication operations. Our machines perform tried-and-true fabrication methods, such as punching and forming, and more recent methods, like laser cutting. We’re always looking for innovative technologies that could offer new benefits to our customers.

How ASM’s Metal Fabrication Process Works

At Approved Sheet Metal, we’re known for having an efficient fabrication process that yields excellent results.

Design for Manufacturability Feedback

In this initial stage, our team reviews your CAD design to determine the requirements for the project and optimize the design for manufacturability. We have an unusually high number of in-house engineering experts who can collaborate with you on your overall design or help you troubleshoot individual design elements.

For advice on a full range of sheet metal fabrication design topics, you can also download our Sheet Metal Design for Manufacturing eBook.

Quote / Order Placing

Once your design is complete, you’ll request a quote for a prototype on our website. Our online quoting system will prompt you to include all the critical information we need to provide you with an accurate quote.

Gathering information up front reduces back and forth. And because our system is entirely digital, all of your project details are automatically added to our work queue—no manual data entry is required. Ultimately, our efficient approach to quoting and order placing ensures that we can start your project quickly and seamlessly.

Programming

When your part is ready to enter production, our team uses a 3D CAD model to program our laser cutter, press brake, or other computer-controlled machines used in the fabrication of your part. This automated process removes the risk of human error and allows us to identify potential issues with the part before fabrication begins.

Fabrication

Next, fabrication begins using one or more of our in-house metal fabrication processes, such as laser cutting, punching, forming, or welding. Many parts require several different operations.

Finishing (optional)

If you request finishing services, we will clean and prepare your parts in accordance with the finishing method you choose and then apply a high-quality finish.

Assembly (optional)

We have the in-house expertise to conduct a complete manufacturing workflow for your parts under our roof, including assembly. If you need help determining the best joining method for your assembly (e.g., welding vs. fastening), we’re always happy to advise.

Ready to partner with a metal fabrication shop you can trust? Request a quote to get started today!

Metal Fabrication FAQ

Metal fabrication encompasses various techniques used to manipulate flat metal into diverse shapes and structures. Processes such as forming, bending, cutting, punching, stamping, shearing, welding, and assembly are fundamental to metal fabrication.

The categories are Structural Fabrication (focuses on large-scale components for construction), Industrial Fabrication (manufacturing for industrial applications), Commercial Fabrication (crafting for commercial enterprises), and Precision Metal Fabrication (highly accurate parts).

recision sheet metal fabrication finds applications in electronics enclosures, aerospace components, automotive parts, medical equipment, HVAC systems, appliance manufacturing, consumer electronics, architectural metalwork, and more.

Fabricators often work with aluminum, cold-rolled steel, copper, and stainless steel, utilizing sheets up to ¼ inch thick to create precise components.

The critical operations include laser cutting (for precise designs), punching (creating holes and intricate shapes), forming (reshaping metal), hardware insertion (enhancing functionality), welding (creating strong bonds), and finishing (powder coating, silk screening, plating, etc.).

The process begins with design optimization for manufacturability, followed by efficient quoting and order placement. Automation, CAD software, and state-of-the-art machinery are employed to program and execute the fabrication process accurately, ensuring minimal errors and precise outcomes.

Finishing includes services like powder coating, silk screening, plating, and more, enhancing aesthetics and durability. Assembly services involve complete manufacturing workflows, including joining methods like welding or fastening.