Last updated on May 21st, 2025 at 12:48 pm

EMI/RFI shielding provides critical protection against electromagnetic and radio frequency interference for many electronics components and assemblies. Without proper shielding, electronic devices may suffer from lower performance, malfunctions, or—worse—complete failure.

Though often presented as interchangeable terms, there are critical differences between EMI and RFI shielding. Here, we’ll explore both types of interference protection, which industries and applications rely on each, and why you can trust Approved Sheet Metal with your custom sheet metal fabrication needs.

Table of Contents

- 1 What Is EMI/RFI Shielding?

- 2 Material Selection Trade-offs for EMI/RFI Shielding

- 3 ASM’s EMI/RFI Shielding Capabilities

- 4 EMI / RFI Shielding in Sheet Metal Fabrication FAQ

- 4.0.1 What is the difference between EMI and RFI shielding?

- 4.0.2 Why is EMI/RFI shielding important for electronic devices?

- 4.0.3 Which industries rely on EMI shielding, and for what applications?

- 4.0.4 What are some common applications of RFI shielding?

- 4.0.5 How does Approved Sheet Metal (ASM) support EMI/RFI shielding needs?

What Is EMI/RFI Shielding?

EMI (“electromagnetic interference”) and RFI (“radio frequency interference”) shielding are processes used to protect electronic devices and circuits from related forms of interference and radiation.

EMI shielding

More often than not, electromagnetic interference is generated by power lines, radio transmitters, motors, and even other electronic devices. This type of interference can have adverse effects on electronics components of all kinds, namely on their circuitry and transmission ability.

To maintain the integrity and reliability of these systems, EMI shielding uses conductive metals or coatings that effectively create barriers to absorb or reflect electromagnetic waves.

EMI shielding is a benchmark for applications in a range of industries, including:

- Consumer electronics: Many consumer electronics products (e.g., laptops, smartphones, TVs, gaming consoles, and home appliances) feature EMI shielding.

- Telecommunications: EMI shielding is crucial not only for mobile phones but also for telecommunications base stations, antennas, and network infrastructure.

- Healthcare: EMI shielding offers protection and safety for medical devices and equipment ranging from MRI and CT machines to pacemakers and other monitoring devices.

- Aerospace and defense: Many applications in these industries—such as electronic systems onboard aircraft, satellites, missiles, and radar systems—require EMI shielding for protection against electromagnetic pulse (EMP) events and other related forms of EM interference.

- Automotive: In this industry, EMI shielding ensures reliable operation and regulatory compliance for engine control units, infotainment systems, navigation systems, and safety sensors.

RFI shielding

Radio frequency interference can come from a variety of sources, including mobile phones, Wi-Fi networks, radio transmitters, and other electronic devices that may be operating at specific radio frequencies. In response, RFI shielding is intended to protect wireless communication, data transmission, and reception systems from this type of interference.

RFI shielding is essential for many of the same industries that rely on EMI shielding; however, RFI shielding tends to be used for different purposes. For example:

- Wireless communication devices and systems (including cellular networks, Wi-Fi routers, Bluetooth devices, RFID systems, and satellite communication systems) use RFI shielding to protect signal quality.

- In broadcasting and entertainment, one can find RFI shielding in television and radio transmitters, studio equipment, broadcasting equipment, and AV receivers.

- RFI shielding is a mainstay in industrial automation, where it is integrated into programmable logic controllers, motor drives, and sensors, among other devices.

- Military and security applications (e.g., RF jamming systems, surveillance equipment, encrypted communication devices, electronic warfare systems) regularly include RFI shielding to shore up performance and security.

Material Selection Trade-offs for EMI/RFI Shielding

Choosing the right material for EMI/RFI shielding is critical to balancing performance, manufacturability, cost, and durability. Each material offers unique electrical, mechanical, and environmental properties that impact shielding effectiveness and long-term reliability.

| Material | Conductivity | Corrosion Resistance | Shielding Effectiveness | Magnetic Permeability | Formability | Cost |

|---|---|---|---|---|---|---|

| Copper | Excellent | Moderate (can oxidize) | Excellent (up to GHz) | Low | Good | High |

| Aluminum | Very Good | Very Good (lightweight) | Good | Low | Excellent | Moderate |

| Tin-Plated Steel | Good | Very Good | Good | Moderate | Moderate | Moderate |

| Nickel Silver | Good | Excellent | Very Good | Low | Good | High |

| Mu-metal | Moderate | Poor | Excellent (Low-frequency) | Very High | Poor (brittle) | Very High |

| Stainless Steel | Fair | Excellent | Moderate | Low to Moderate | Poor (harder to cut/form) | Moderate to High |

Key Considerations

- Frequency Range: Mu-metal is ideal for low-frequency magnetic shielding, while copper and aluminum are better suited for high-frequency EMI.

- Environmental Exposure: In corrosive environments, tin-plated or stainless steel offers better long-term resistance than raw copper.

- Mechanical Constraints: Aluminum is a top choice for lightweight, high-formability applications; stainless steel, while durable, can be challenging to form.

- Cost and Availability: Material choice may be driven by production volume and budget—copper and nickel silver provide premium performance but come with higher costs.

By selecting the optimal material early in the design phase, you can prevent over-engineering and reduce total lifecycle costs while ensuring compliance with EMI/RFI shielding requirements.

ASM’s EMI/RFI Shielding Capabilities

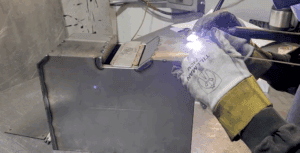

Unlike many fabrication companies in Boston, MA, and elsewhere, ASM has over 30 years of experience working with leaders from these industries to design and fabricate high-precision EMI/RFI shields. Over these years, we’ve honed our custom sheet metal fabrication capabilities, including laser cutting, forming, and hardware insertion, which are commonly used in this type of work.

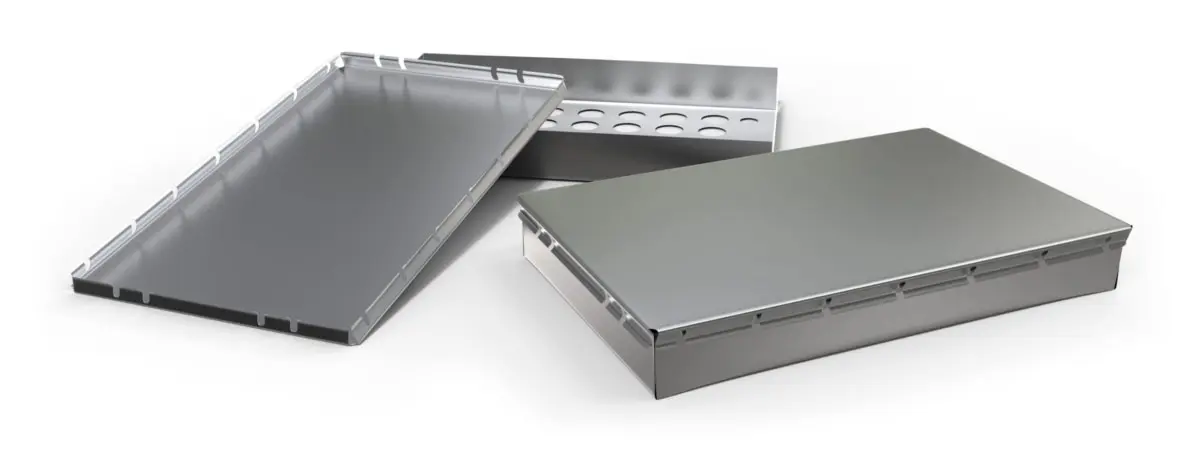

This experience has given us unique insight into the materials regularly used for components and assemblies that incorporate EMI/RFI shielding. Whether we’re fabricating multi-cavity, surface mount, snap-in, or one-piece shields, we offer a complete range of metal options (including copper, aluminum, nickel, steel, tin-plated steel) to inhibit EM and RF interference.

When we fabricate your EMI/RFI shields, we’ll provide you with any finishing and plating option that you choose. Whether you opt for color anodizing, powder coating, engraving, or another custom finish, we’ll work in lockstep with you to maximize your parts' performance and EMI/RFI resilience.

Finally, we’re just as comfortable fabricating a handful of prototypes as we are collaborating on bigger production runs. Whatever your EMI/RFI shielding needs might be, our custom sheet metal fabrication shop is ready to serve you.

Looking for EMI/RFI shielding to protect your next product? Request a quote today!